The primary technical significance of using molybdenum disilicide (MoSi2) heating elements lies in their ability to sustain a stable 1500°C environment essential for liquid-phase sintering. This specific thermal capacity allows for precise temperature control curves, which are critical for facilitating the chemical reactions required to densify red mud-alumina composites without the application of external mechanical pressure.

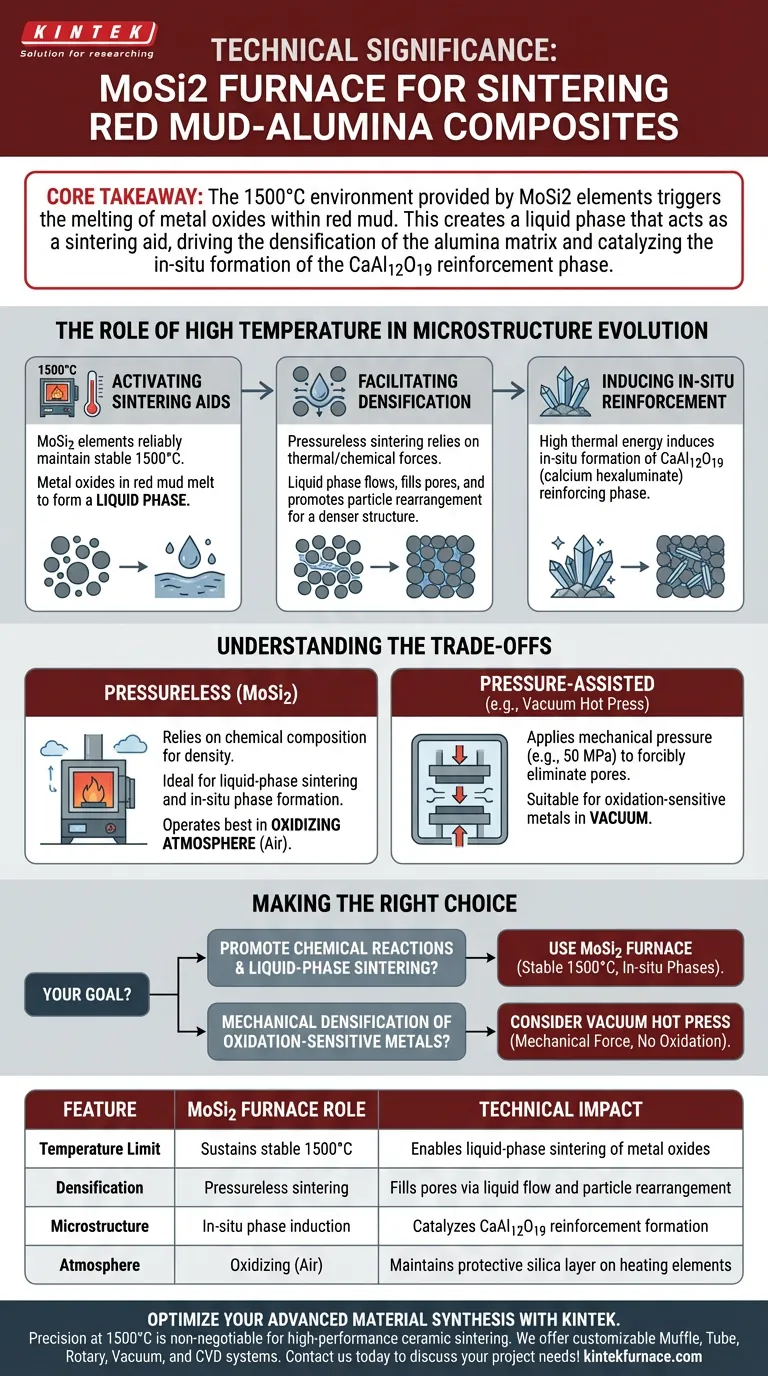

Core Takeaway The 1500°C environment provided by MoSi2 elements triggers the melting of metal oxides within red mud. This creates a liquid phase that acts as a sintering aid, driving the densification of the alumina matrix and catalyzing the in-situ formation of the CaAl12O19 reinforcement phase.

The Role of High Temperature in Microstructure Evolution

Activating Sintering Aids

Standard heating elements often degrade or lose stability at temperatures required for advanced ceramics. MoSi2 elements specifically enable the furnace to reach and maintain 1500°C reliably.

At this temperature, the metal oxides naturally present in the red mud undergo a phase transition. They melt to form a liquid phase, which is the mechanism that differentiates this process from solid-state sintering.

Facilitating Densification

In pressureless sintering, densification relies entirely on thermal and chemical driving forces rather than mechanical force.

The liquid phase generated by the high temperature flows between the solid alumina particles. This action fills pore spaces and promotes particle rearrangement, leading to a denser final composite structure.

Inducing In-Situ Reinforcement

The precise thermal control allows for specific chemical reactions to occur within the composite matrix.

The high thermal energy induces the formation of CaAl12O19 (calcium hexaluminate). This phase is not added externally; it forms "in-situ" (during the process) thanks to the reaction between the red mud components and the alumina, acting as a reinforcement phase to improve the material's properties.

Understanding the Trade-offs

Pressureless vs. Pressure-Assisted Sintering

While the MoSi2 furnace excels at pressureless sintering, it relies heavily on the chemical composition of the red mud to achieve density.

If the "liquid phase" formation is insufficient, the material may retain porosity. In contrast, techniques like vacuum hot pressing (mentioned in supplementary contexts) apply mechanical pressure (e.g., 50 MPa) to forcibly eliminate pores.

Atmosphere Limitations

MoSi2 elements typically operate best in oxidizing atmospheres (air) because they form a protective silica layer.

If your process requires a high vacuum to prevent oxidation of metallic components (as seen in copper or aluminum sintering), a standard MoSi2 box furnace may not be suitable without specific atmospheric control modifications.

Making the Right Choice for Your Goal

To determine if a high-temperature MoSi2 furnace is the correct tool for your composite development, consider your specific material objectives:

- If your primary focus is promoting chemical reactions and liquid-phase sintering: Utilize a MoSi2 furnace to achieve the stable 1500°C temperatures required to activate internal sintering aids and form in-situ phases like CaAl12O19.

- If your primary focus is mechanical densification of oxidation-sensitive metals: Consider a vacuum hot press furnace to apply mechanical force and prevent oxidation, as pressureless sintering in air may not achieve full density for these materials.

Ultimately, the MoSi2 furnace is the technical enabler for converting the waste oxides in red mud into functional sintering agents through precise high-temperature management.

Summary Table:

| Feature | MoSi2 Furnace Role | Technical Impact |

|---|---|---|

| Temperature Limit | Sustains stable 1500°C | Enables liquid-phase sintering of metal oxides |

| Densification | Pressureless sintering | Fills pores via liquid flow and particle rearrangement |

| Microstructure | In-situ phase induction | Catalyzes CaAl12O19 reinforcement formation |

| Atmosphere | Oxidizing (Air) | Maintains protective silica layer on heating elements |

Optimize Your Advanced Material Synthesis with KINTEK

Precision at 1500°C is non-negotiable for high-performance ceramic sintering. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique lab requirements.

Whether you are pursuing liquid-phase sintering with MoSi2 elements or require vacuum hot pressing for mechanical densification, our high-temperature solutions provide the thermal stability needed to drive in-situ reinforcement and full material density.

Ready to elevate your composite research? Contact us today to discuss your project needs!

Visual Guide

References

- Yongliang Chen, Shiwei Jiang. Wettability and Mechanical Properties of Red Mud–Al2O3 Composites. DOI: 10.3390/ma17051095

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What advantages does choosing the right ceramic heating element supplier offer? Secure a Strategic Partner for Peak Performance

- Why are both external and internal thermocouples required for pyrolysis? Optimize Your Thermal Reaction Monitoring

- What types of materials are used in heating elements and why? Discover the Best Choices for Your Application

- What is the maximum operating temperature for MoSi2 heating elements? Achieve Reliable High-Temp Performance

- Why are multiple sets of resistance heaters used in varying positions for calorimeter calibration? Ensure Spatial Accuracy

- What are the key advantages of MoSi2 heating elements? Achieve High-Temp Reliability and Efficiency

- Why is the miniaturization of halogen filaments necessary? Essential Precision for Floating-Zone Growth

- What are the safety advantages of ceramic heating elements over electric heating wires? Discover Inherent Electrical and Fire Safety