The material at the heart of any heating element is chosen for its ability to convert electrical energy into heat efficiently and reliably. The most common materials are metallic alloys, primarily nichrome (nickel-chromium) and Kanthal (iron-chromium-aluminum). For more extreme temperatures or specialized environments, non-metallic materials like silicon carbide and molybdenum disilicide are used.

The selection of a heating element material is a deliberate engineering trade-off. It is not about finding one "best" substance, but about balancing a material's electrical resistance, high-temperature durability, and resistance to oxidation against the cost and operating environment of a specific application.

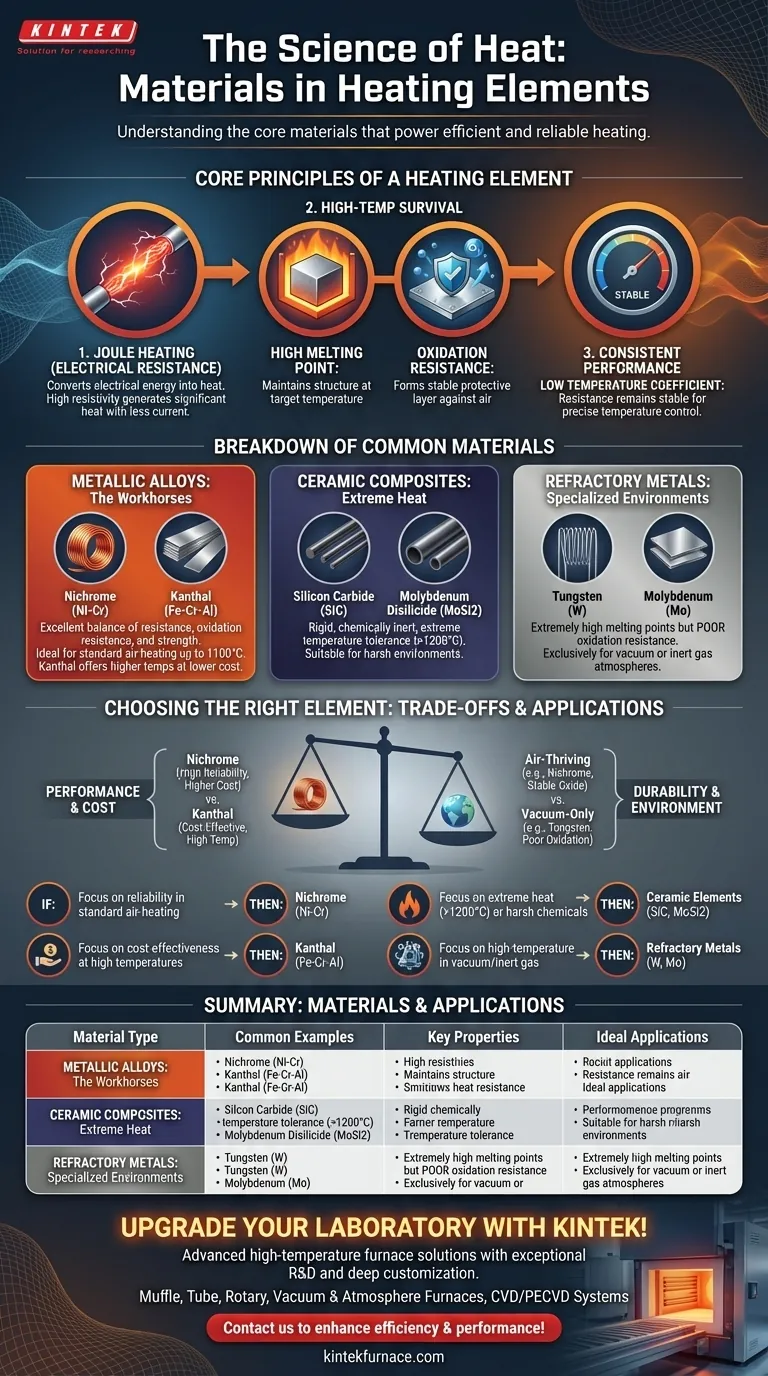

The Core Principles of a Heating Element

To understand why certain materials are used, we must first understand the fundamental requirements of the job. A heating element's primary function is to get hot when electricity passes through it and to survive doing so repeatedly.

The Role of Electrical Resistance

Every heating element operates on a principle known as Joule heating. When an electric current flows through a material with electrical resistance, energy is converted into heat.

A material with high resistivity is ideal. It generates significant heat with less current compared to a low-resistance material, making the system more efficient and compact.

Surviving High Temperatures

The chosen material must be able to withstand its own heat without degrading. Two properties are critical here: a high melting point and resistance to oxidation.

A high melting point ensures the element remains solid and structurally stable at its target operating temperature.

Oxidation resistance is arguably the most critical factor for longevity. At high temperatures, most metals react with oxygen in the air, forming an oxide layer that can cause the element to become brittle and fail. Materials like nichrome are prized because they form a stable, protective oxide layer that prevents further corrosion.

Ensuring Consistent Performance

For predictable and controlled heating, the element's resistance should remain relatively stable as its temperature changes. This property is known as a low temperature coefficient of resistance.

If a material's resistance changes dramatically with heat, the power output will fluctuate, making it difficult to maintain a precise temperature.

A Breakdown of Common Heating Element Materials

Materials are generally grouped into categories based on their composition and ideal operating conditions. Each has a distinct profile of strengths and weaknesses.

Metallic Alloys: The Workhorses

These are the most common materials found in everyday appliances and industrial furnaces.

- Nichrome (Nickel-Chromium): Often considered the gold standard, nichrome (typically 80% nickel, 20% chromium) offers an excellent combination of high resistance, superb oxidation resistance, and good ductility. It maintains its strength well at high temperatures.

- Kanthal (Iron-Chromium-Aluminum): A leading alternative to nichrome, Fe-Cr-Al alloys are less expensive and can often operate at even higher temperatures. Their primary advantage is cost-effectiveness for high-temperature applications.

Ceramic Composites: For Extreme Heat

When temperatures exceed the limits of metallic alloys, ceramic-based materials are required.

- Silicon Carbide (SiC): This material is rigid, chemically inert, and can operate in open air at very high temperatures. It is often formed into rods or tubes.

- Molybdenum Disilicide (MoSi2): Known for its exceptional high-temperature performance and resistance to corrosion, MoSi2 is used in the most demanding industrial and laboratory furnaces.

Refractory Metals: For Specialized Environments

These metals have extremely high melting points but one critical weakness: they oxidize almost instantly in air at high temperatures.

- Tungsten and Molybdenum: These materials are used exclusively in vacuum furnaces or environments filled with an inert gas. Their poor oxidation resistance makes them entirely unsuitable for heating in open air.

Understanding the Trade-offs

Choosing a heating element is never about a single metric. It is always a balance of competing factors.

Performance vs. Cost

Nichrome offers fantastic all-around performance and reliability, but it comes at a higher cost due to its high nickel content. Kanthal (Fe-Cr-Al) provides a more economical solution for many high-temperature applications, representing a direct trade-off between material cost and specific performance characteristics.

Durability vs. Environment

The operating atmosphere is a non-negotiable constraint. A material like Tungsten has a phenomenal melting point but will be destroyed in seconds if operated in air. Conversely, a nichrome element is specifically designed to thrive in air by forming its own protective oxide layer.

Temperature Range vs. Material Class

A simple mental model helps guide selection. For general-purpose heating up to around 1100°C (2000°F), metallic alloys are the go-to choice. For extreme heat above that, ceramic composites are necessary. For high heat in a controlled vacuum, refractory metals are the only option.

Making the Right Choice for Your Application

Your final decision should be guided by your primary goal and operating constraints.

- If your primary focus is reliability in standard air-heating applications: Nichrome (Ni-Cr) alloys are the proven, trusted industry standard for longevity and consistent performance.

- If your primary focus is cost-effectiveness at high temperatures: Iron-chromium-aluminum (Fe-Cr-Al) alloys like Kanthal offer an excellent balance of high-temperature capability and lower material cost.

- If your primary focus is operating in extreme heat (above 1200°C) or harsh chemical environments: Ceramic elements like Silicon Carbide (SiC) or Molybdenum Disilicide (MoSi2) are the necessary choice.

- If your primary focus is high-temperature heating within a vacuum or inert atmosphere: Refractory metals like Tungsten or Molybdenum are required due to their high melting points and inability to survive in oxygen.

Understanding these core material properties empowers you to select an element engineered for performance, longevity, and efficiency in your specific context.

Summary Table:

| Material Type | Common Examples | Key Properties | Ideal Applications |

|---|---|---|---|

| Metallic Alloys | Nichrome, Kanthal | High resistivity, oxidation resistance, stable performance | Standard air-heating up to 1100°C, cost-effective solutions |

| Ceramic Composites | Silicon Carbide, Molybdenum Disilicide | Extreme temperature tolerance, chemical inertness | High-temperature (>1200°C) or harsh environments |

| Refractory Metals | Tungsten, Molybdenum | Very high melting points, poor oxidation resistance | Vacuum or inert gas atmospheres only |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable heating systems. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Contact us today to discuss how we can enhance your efficiency and performance!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What recent advancements have been made in MoSi2 heating elements? Optimize for Extreme Temperatures and Reactive Atmospheres

- What heating elements are used in furnaces designed for higher temperatures? Explore SiC, MoSi2, Molybdenum, and Graphite Solutions

- How do silicon carbide heating elements reduce operating costs? Achieve Long-Term Savings and Efficiency

- How can the service life of silicon carbide heating elements be prolonged? Extend Lifespan with Expert Tips

- Why is platinum selected as a heating zone material for SEM furnaces? Ensuring High-Contrast Imaging at 1300°C

- What are the main advantages of graphite heating elements in vacuum ovens? Unlock Extreme Heat & Purity

- What are the maintenance requirements for MoSi2 heating elements? Ensure Longevity with Proper Care

- What metal treatment processes employ MoSi2 heating elements? Unlock High-Temp Efficiency for Your Lab