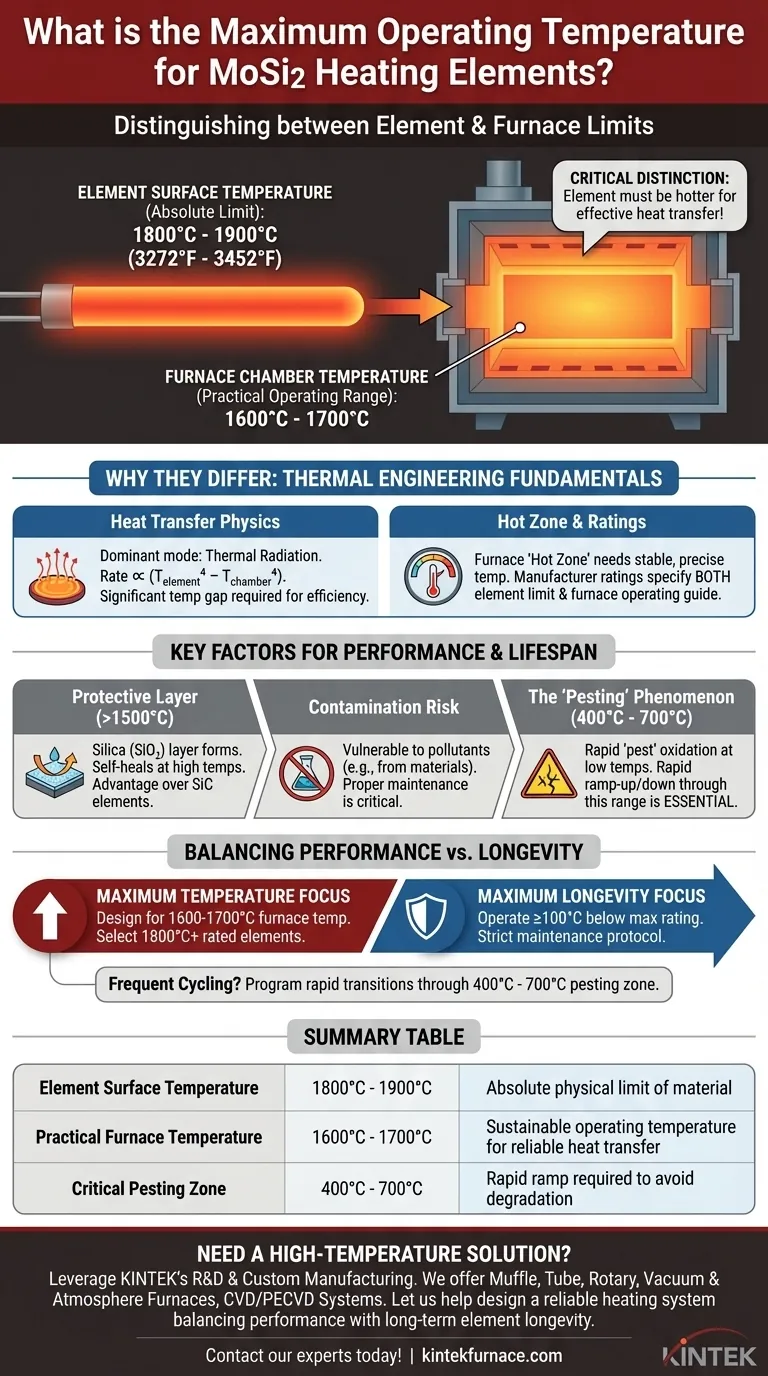

The absolute maximum surface temperature for a MoSi2 heating element is typically between 1800°C and 1900°C (3272°F to 3452°F). However, this figure represents the element's physical limit, not the sustainable operating temperature of the furnace it is in. For practical applications, the maximum furnace chamber temperature is significantly lower, generally in the range of 1600°C to 1700°C.

The critical distinction you must understand is between the element's surface temperature and the furnace's maximum chamber temperature. While the element itself can get hotter, the practical and safe operating temperature for the furnace it heats is limited to a lower range to ensure effective heat transfer and a reasonable service life.

Why Element Temperature and Furnace Temperature Differ

The difference between the element's rating and the furnace's capability is not a discrepancy; it is a fundamental principle of thermal engineering. An element must be substantially hotter than its surroundings to transfer heat efficiently.

The "Hot Zone" vs. The Element Surface

The internal chamber of a furnace, often called the "hot zone," is the area that needs to be held at a precise, stable temperature. To heat this volume of space and overcome heat loss, the heating elements surrounding it must operate at a higher temperature.

The Physics of High-Temperature Heat Transfer

At the extreme temperatures where MoSi2 elements operate, the dominant mode of heat transfer is thermal radiation. The rate of heat transfer is proportional to the difference in temperature to the fourth power (T_element⁴ - T_chamber⁴). This requires a significant temperature gap to drive heat into the chamber effectively.

Manufacturer Ratings Clarify This Distinction

Reputable manufacturers will specify both the maximum element temperature and the recommended maximum furnace operating temperature. The element's maximum rating (e.g., 1850°C) is a statement of material limits, while the furnace rating (e.g., 1700°C) is the practical guide for design and operation.

Key Factors Influencing Performance and Lifespan

Simply knowing the maximum temperature is not enough. The longevity and reliability of MoSi2 elements depend heavily on how they are operated and maintained.

The Advantage Above 1500°C

MoSi2 elements form a protective glassy layer of silica (SiO₂) on their surface when heated. This layer self-heals at high temperatures, giving these elements a distinct advantage and longer life compared to silicon carbide (SiC) elements when operated consistently above 1500°C.

The Risk of Contamination

The protective silica layer is vulnerable. Contaminants, such as those from improperly dried colored zirconia or other process materials, can attack this layer and cause premature element failure. Proper furnace maintenance and clean operation are critical.

Understanding the Trade-offs and Pitfalls

While powerful, MoSi2 elements have specific vulnerabilities that must be managed to ensure a successful outcome. Operating them without understanding these trade-offs leads to unexpected costs and downtime.

The "Pesting" Phenomenon at Low Temperatures

MoSi2 elements are susceptible to a specific type of failure known as "pest" oxidation or "pesting." This occurs at lower temperatures, typically between 400°C and 700°C, where the material can rapidly disintegrate into a powder. Furnaces must be designed to heat and cool through this temperature range as quickly as possible.

Pushing to the Absolute Limit

Operating an element at its absolute maximum rated temperature will drastically shorten its lifespan. Heat transfer becomes less efficient, and the protective layer degrades more rapidly. A conservative approach is always more cost-effective in the long run.

Brittleness and Handling

At room temperature, MoSi2 elements are very brittle and must be handled with extreme care during installation and replacement. They become more ductile only at very high temperatures.

Making the Right Choice for Your Application

Your operational strategy should be dictated by your primary engineering goal, whether it is achieving maximum temperature or ensuring maximum reliability.

- If your primary focus is maximum furnace temperature: Design for a continuous operating temperature of 1600°C to 1700°C, which requires selecting elements rated for 1800°C or higher.

- If your primary focus is element longevity: Operate the furnace at least 100°C below its maximum rated temperature and implement a strict maintenance protocol to prevent contamination.

- If your process involves frequent thermal cycling: Ensure your controller is programmed to ramp up and down quickly through the 400°C to 700°C range to avoid pest oxidation.

Understanding the distinction between element capability and practical furnace operation is the key to designing a reliable, high-performance heating system.

Summary Table:

| Temperature Type | Typical Range | Key Consideration |

|---|---|---|

| Element Surface Temperature | 1800°C - 1900°C | Absolute physical limit of the MoSi2 material |

| Practical Furnace Temperature | 1600°C - 1700°C | Sustainable operating temperature for reliable heat transfer |

| Critical Pesting Zone | 400°C - 700°C | Rapid ramp-up/down required to avoid element degradation |

Need a High-Temperature Furnace Solution Tailored to Your Specific Requirements?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let us help you design a reliable heating system that balances maximum temperature performance with long-term element longevity. Contact our experts today to discuss your application needs!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability