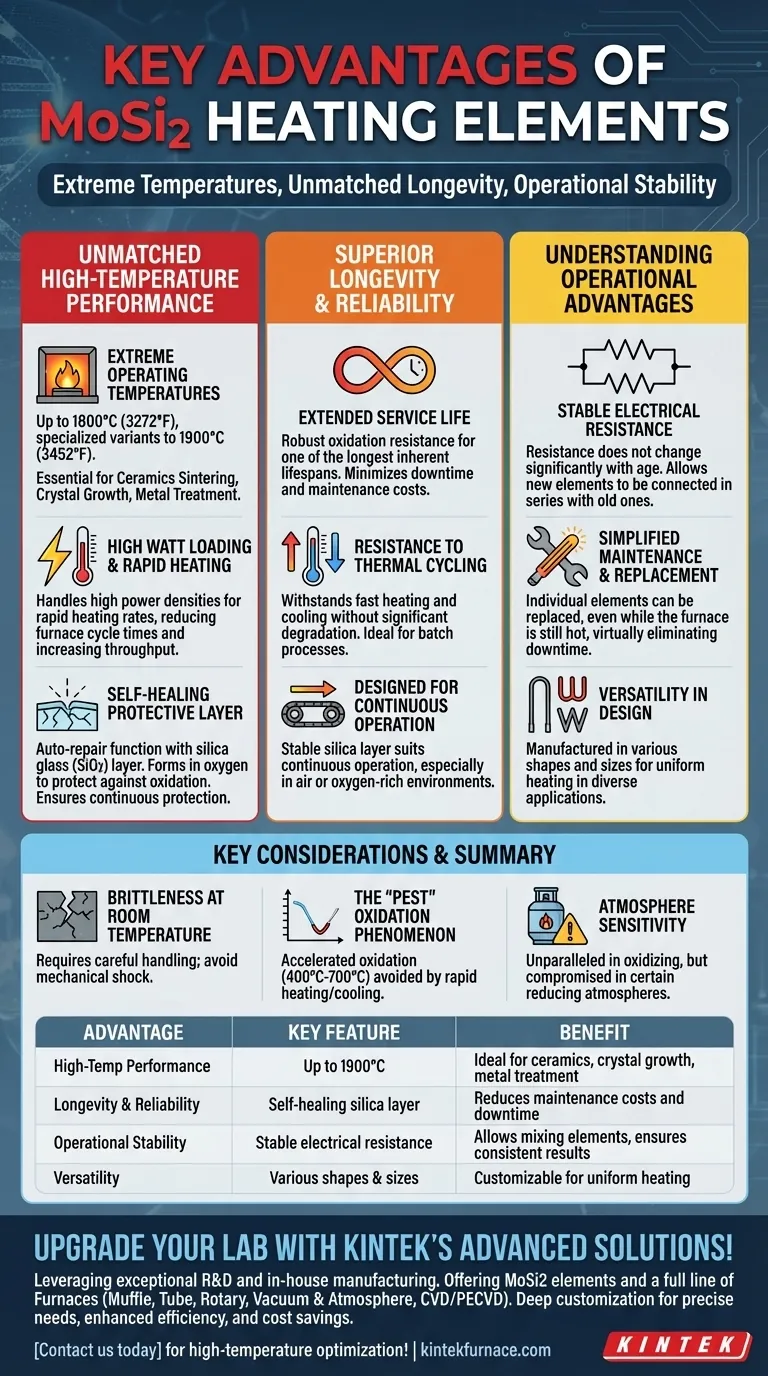

At their core, the primary advantages of Molybdenum Disilicide (MoSi2) heating elements are their capacity for extremely high operating temperatures, unmatched service life, and remarkable operational stability. These attributes make them a superior choice for the most demanding industrial and laboratory furnace applications where performance and reliability are non-negotiable.

While many materials can get hot, MoSi2 elements are unique because they thrive in extreme heat. Their ability to form a self-healing protective layer in oxygen ensures exceptional longevity and predictable performance, fundamentally lowering the total cost of ownership in high-temperature processes.

Unmatched High-Temperature Performance

The defining characteristic of MoSi2 is its ability to perform reliably at temperatures that would destroy most other metallic heating elements. This capability is the foundation for its use in advanced thermal processing.

Extreme Operating Temperatures

MoSi2 elements can operate continuously at temperatures up to 1800°C (3272°F), with some specialized variants reaching as high as 1900°C (3452°F). This makes them indispensable for processes like ceramics sintering, crystal growth, and metal heat treatment.

High Watt Loading and Rapid Heating

These elements can handle very high power densities, or watt loadings. This allows for extremely rapid heating rates, significantly reducing furnace cycle times and increasing throughput.

The Self-Healing Protective Layer

The key to MoSi2's high-temperature durability is its "auto-repair" function. When heated in an oxygen-containing atmosphere, a thin, non-porous layer of silica glass (SiO2) forms on the element's surface. If this layer is cracked or damaged, the underlying MoSi2 is exposed to oxygen and immediately "heals" the breach with new silica, ensuring continuous protection against oxidation.

Superior Longevity and Reliability

Beyond pure temperature, MoSi2 elements are engineered for long-term, continuous operation, which minimizes downtime and maintenance costs.

Extended Service Life

Due to their robust oxidation resistance, MoSi2 elements possess one of the longest inherent lifespans of any electric heating element technology. This reduces the frequency of costly replacement cycles and associated labor.

Resistance to Thermal Cycling

The elements are capable of undergoing fast thermal cycling—rapid heating and cooling—without suffering significant degradation or fatigue. This makes them ideal for batch processes that require frequent temperature changes.

Designed for Continuous Operation

The stability of the protective silica layer makes MoSi2 perfectly suited for continuous operation, especially in air or oxygen-rich environments.

Understanding the Operational Advantages

MoSi2 elements offer practical benefits that simplify furnace design, operation, and maintenance.

Stable Electrical Resistance

Unlike many other heating elements, the electrical resistance of MoSi2 does not change significantly with age or use. This is a critical advantage, as it allows new elements to be connected in series with old ones without affecting performance.

Simplified Maintenance and Replacement

The stability of MoSi2 allows for individual elements to be replaced without having to replace the entire set. Many furnace designs even permit elements to be replaced while the furnace is still hot, virtually eliminating downtime for maintenance.

Versatility in Design

MoSi2 elements can be manufactured in a wide variety of shapes and sizes, including common U-shaped, W-shaped, and straight configurations. This allows furnace designers to optimize heating uniformity and power for specific applications.

Key Considerations and Trade-offs

To leverage MoSi2 effectively, it is crucial to understand its specific material properties and limitations.

Brittleness at Room Temperature

MoSi2 is a cermet (ceramic-metal composite) and is quite brittle at lower temperatures. It requires careful handling and installation to prevent mechanical shock or fracture.

The "Pest" Oxidation Phenomenon

In a specific low-temperature range of approximately 400°C to 700°C, MoSi2 can undergo accelerated oxidation, known as "pest" oxidation, which can cause the material to disintegrate. This is avoided by ensuring the furnace heats or cools rapidly through this temperature zone.

Atmosphere Sensitivity

While unparalleled in oxidizing atmospheres, MoSi2 performance can be compromised in certain reducing or reactive atmospheres that attack the protective silica layer. The operating environment must always be considered during material selection.

Making the Right Choice for Your Goal

Selecting MoSi2 is a decision based on achieving specific performance outcomes for your thermal process.

- If your primary focus is maximum process temperature and speed: MoSi2 is the definitive choice for applications operating consistently above 1600°C that demand rapid heating.

- If your primary focus is operational uptime and low maintenance: The stable resistance and long life of MoSi2 elements reduce replacement frequency and allow for hot-swapping, maximizing furnace availability.

- If your primary focus is process consistency: The element's resistance to thermal cycling and its stable electrical output ensure highly repeatable and predictable results from batch to batch.

Ultimately, investing in MoSi2 elements is a strategic decision for achieving reliable, efficient, and high-performance thermal processing.

Summary Table:

| Advantage | Key Feature | Benefit |

|---|---|---|

| High-Temperature Performance | Operates up to 1900°C | Ideal for ceramics sintering, crystal growth, and metal treatment |

| Longevity and Reliability | Self-healing silica layer | Reduces maintenance costs and downtime |

| Operational Stability | Stable electrical resistance | Allows mixing old and new elements, ensures consistent results |

| Versatility | Various shapes and sizes | Customizable for uniform heating in diverse applications |

Upgrade your lab's thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide MoSi2 heating elements and a full product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—tailored for diverse laboratories. Our deep customization capability ensures precise fit for your unique experimental needs, delivering enhanced efficiency, reliability, and cost savings. Contact us today to discuss how we can optimize your high-temperature applications!

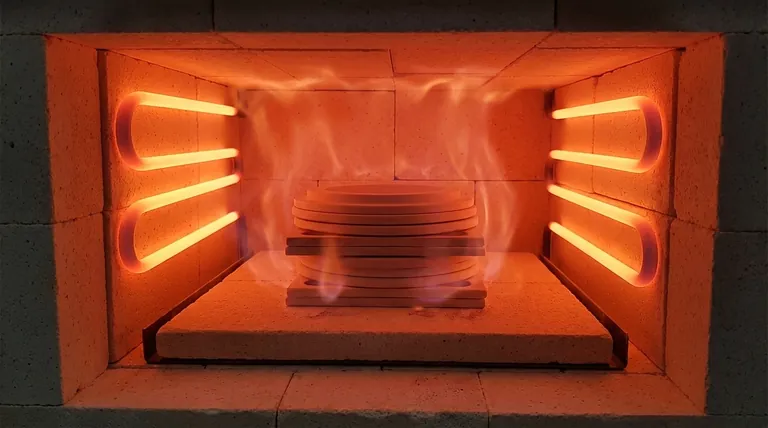

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency