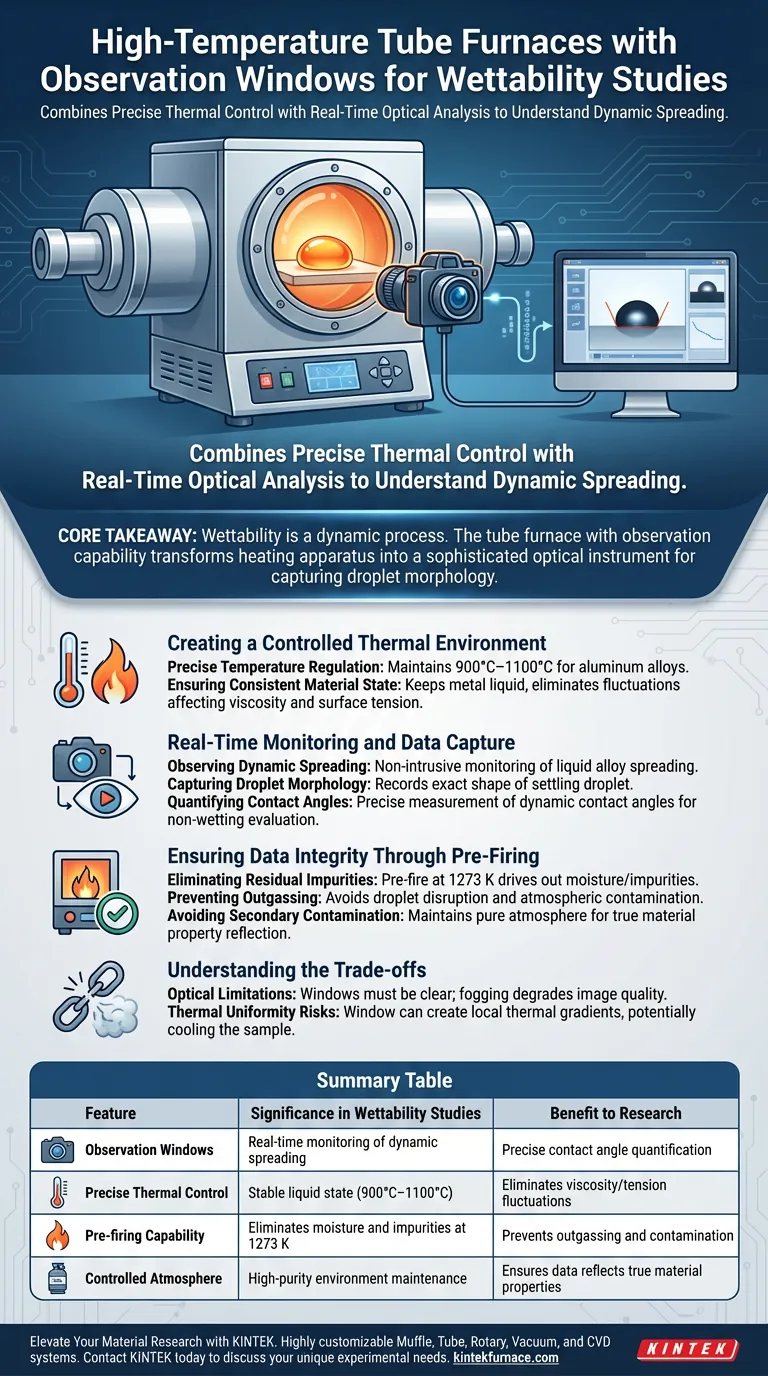

The significance of using a high-temperature tube furnace with observation windows lies in its ability to combine precise thermal control with real-time optical analysis. This setup allows researchers to heat aluminum alloys to a liquid state (900°C–1100°C) while simultaneously recording the dynamic spreading behavior of the droplet on ceramic surfaces. Without the observation windows, it would be impossible to measure the changing contact angles that define the material's wettability and non-wetting characteristics.

Core Takeaway Wettability is a dynamic process, not a static event. The tube furnace with observation capability transforms a standard heating apparatus into a sophisticated optical instrument, enabling the capture of droplet morphology to quantify exactly how liquid metals interact with solid ceramics over time.

Creating a Controlled Thermal Environment

Precise Temperature Regulation

For studying aluminum alloys on specific ceramics like Sr4Al6O12SO4, maintaining a specific temperature range is non-negotiable. The furnace provides a controlled environment between 900°C and 1100°C.

Ensuring Consistent Material State

This thermal precision ensures the aluminum remains in the correct liquid phase throughout the experiment. It eliminates temperature fluctuations that could alter the viscosity or surface tension of the molten metal, ensuring data reliability.

Real-Time Monitoring and Data Capture

Observing Dynamic Spreading

The observation windows serve a critical function: they allow for non-intrusive monitoring. Researchers can watch the liquid aluminum alloy as it physically spreads across the ceramic surface in real-time.

Capturing Droplet Morphology

External cameras record the experiment through these windows. This video data captures the exact shape (morphology) of the metal droplet as it settles.

Quantifying Contact Angles

The visual data allows for the precise measurement of dynamic contact angles. These measurements are the primary metric used to evaluate the non-wetting characteristics of the ceramic material against the molten alloy.

Ensuring Data Integrity Through Pre-Firing

Eliminating Residual Impurities

Beyond the wetting experiment itself, the furnace is essential for sample preparation. It is used to pre-fire porous substrates (e.g., at 1273 K) to completely drive out residual moisture or internal impurities.

Preventing Outgassing

If these impurities remain, they can lead to outgassing when the temperature rises during the actual test. This outgassing can disrupt the droplet surface and contaminate the atmosphere.

Avoiding Secondary Contamination

By preventing outgassing, the furnace ensures the experimental atmosphere remains pure. This prevents secondary contamination, guaranteeing that the wettability measurements reflect the true properties of the materials, not the artifacts of pollution.

Understanding the Trade-offs

Optical Limitations

While observation windows provide crucial data, they also introduce optical challenges. The windows must remain perfectly clear; any deposition or fogging from the furnace atmosphere will degrade the image quality and compromise the accuracy of the contact angle measurement.

Thermal Uniformity Risks

An observation window inherently represents a break in the furnace insulation. Care must be taken to ensure that the window does not create a local thermal gradient, which could cause the sample to be slightly cooler than the set furnace temperature.

Making the Right Choice for Your Goal

To maximize the value of this experimental setup, align your procedure with your specific data requirements:

- If your primary focus is quantifying non-wetting properties: Ensure your video recording system is calibrated to capture high-contrast images of the droplet morphology for accurate angle measurement.

- If your primary focus is data purity and repeatability: Prioritize a high-temperature pre-firing cycle (approx. 1273 K) to eliminate moisture and prevent secondary contamination from outgassing.

The high-temperature tube furnace with observation windows effectively bridges the gap between thermal processing and optical analysis, providing the comprehensive view needed to master solid-liquid interfaces.

Summary Table:

| Feature | Significance in Wettability Studies | Benefit to Research |

|---|---|---|

| Observation Windows | Real-time monitoring of dynamic spreading | Precise contact angle quantification |

| Precise Thermal Control | Stable liquid state (900°C–1100°C) | Eliminates viscosity/tension fluctuations |

| Pre-firing Capability | Eliminates moisture and impurities at 1273 K | Prevents outgassing and contamination |

| Controlled Atmosphere | High-purity environment maintenance | Ensures data reflects true material properties |

Elevate Your Material Research with KINTEK

Unlock unparalleled precision in solid-liquid interface studies. Backed by expert R&D and manufacturing, KINTEK offers highly customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of lab high-temperature applications. Whether you need integrated observation windows for dynamic wettability analysis or specialized thermal gradients, our furnaces provide the stability and clarity your research deserves.

Ready to optimize your thermal processing? Contact KINTEK today to discuss your unique experimental needs with our specialists.

Visual Guide

References

- José A. Rodríguez‐García, Enrique Rocha‐Rangel. Chemical Interaction between the Sr4Al6O12SO4 Ceramic Substrate and Al–Si Alloys. DOI: 10.3390/eng5010025

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a controlled nitrogen atmosphere essential during the high-temperature processing of biomass in a tube furnace?

- Why is a nitrogen atmosphere essential in a tube furnace for LiFePO4 synthesis? Prevent Oxidation & Ensure Purity

- How did the tube furnace originate and where is it commonly used today? Discover Its Evolution and Modern Applications

- What are the key applications of tube furnaces in materials research and chemistry? Unlock Precise High-Temperature Processing

- How is the silver contamination inside a quartz tube addressed? 1000°C Thermal Cleaning for Pure CVD Results

- What technical advantages do three-zone tube furnaces offer? Superior Temperature Control and Flexibility

- What role does a laboratory tube furnace play in STO thin film annealing? Unlock Neuromorphic Potential

- What is the function of a dual-zone tube furnace in LPCVD? Master Precise MnSe Nanosheet Synthesis