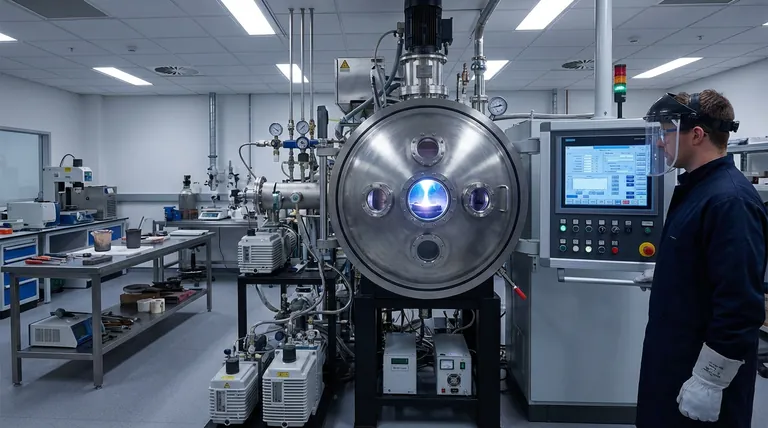

The Vacuum-arc melting furnace is the foundational synthesis equipment for Ti–Mo–Fe alloys, acting as the primary vessel where raw metal powders are converted into a solid, usable alloy.

Its role is twofold: it generates the extreme instantaneous heat necessary to melt refractory metals like titanium and molybdenum, while simultaneously isolating the material in a vacuum or argon environment to prevent catastrophic oxidation. Without this specific furnace type, achieving a chemically accurate and pure Ti–Mo–Fe alloy would be impossible due to the high reactivity of titanium.

Core Takeaway The Vacuum-arc melting furnace is essential for synthesizing Ti–Mo–Fe alloys because it combines high-temperature arc energy to melt refractory elements with a protective atmosphere to ensure purity. Its ability to facilitate multiple remelting cycles is the key factor in achieving the atomic-level homogeneity required for high-performance applications.

Overcoming Thermal and Chemical Barriers

Melting High-Temperature Elements

The primary challenge in creating Ti–Mo–Fe alloys is the high melting point of the constituent elements, particularly titanium and molybdenum.

The vacuum-arc furnace utilizes high-temperature electric arcs to generate intense, localized heat. This allows it to rapidly and completely melt metal powders that standard furnaces cannot efficiently process.

Preventing Atmospheric Contamination

Titanium is highly reactive; it readily absorbs oxygen and nitrogen from the air when heated, which ruins the alloy's mechanical properties.

To prevent this, the furnace operates under a high vacuum or a controlled argon protective atmosphere. This isolation ensures that the titanium matrix remains pure and that the final chemical composition matches the intended design without impurity-induced defects.

Achieving Structural Consistency

The Necessity of Electromagnetic Stirring

Melting the metals is only half the battle; ensuring they mix perfectly is the other.

The electric arc generates an electromagnetic stirring effect within the molten pool. This natural agitation helps break down clusters of individual elements, forcing the iron, molybdenum, and titanium to mix at a fundamental level.

The Process of Flipping and Remelting

A single melting cycle is rarely sufficient to produce a high-quality alloy.

To eliminate compositional segregation—where elements like iron might clump together—the alloy ingots must be flipped and remelted multiple times. Standard practice dictates a minimum of three melting cycles. This repetitive process ensures that alloying elements are distributed uniformly throughout the matrix, preventing localized chemical deviations that could lead to structural failure.

Understanding the Trade-offs

Synthesis vs. Heat Treatment

It is critical not to confuse the role of the Vacuum-arc furnace with that of a Muffle furnace.

The Vacuum-arc furnace is strictly for synthesis and homogenization (melting and mixing). It does not provide the stable, long-term temperature control required for phase stabilization (solution treatment). For stabilizing the beta phase or dissolving brittle intermetallic phases, a Muffle furnace is required after the melting process is complete.

The Risk of Insufficient Cycles

The efficiency of this equipment relies heavily on the operator's adherence to process protocols.

If the "flip and remelt" cycles are skipped or reduced to save time, the alloy will likely suffer from compositional segregation. In Ti–Mo–Fe alloys, this often results in inconsistent distribution of iron, leading to unpredictable mechanical behavior in the final part.

Making the Right Choice for Your Goal

When planning your alloy preparation workflow, consider the following technical priorities:

- If your primary focus is Chemical Purity: Ensure your furnace creates a high-vacuum environment or uses high-purity argon to strictly prevent oxygen uptake by the titanium.

- If your primary focus is Microstructural Homogeneity: Mandate a protocol of at least three remelting cycles with ingot flipping to leverage the arc's electromagnetic stirring effect.

- If your primary focus is Phase Stabilization: Do not rely on the cooling rate of the arc furnace; transfer the homogenized ingot to a Muffle furnace for precise thermal treatment at 1100°C.

The Vacuum-arc melting furnace is not just a heat source; it is a precision mixing tool that solves the twin challenges of titanium's reactivity and molybdenum's heat resistance.

Summary Table:

| Feature | Role in Ti–Mo–Fe Synthesis | Benefit to Final Alloy |

|---|---|---|

| Electric Arc Heat | Melts refractory Mo and Ti | Rapid, complete element fusion |

| Vacuum/Argon Atmosphere | Prevents O2/N2 absorption | High chemical purity and integrity |

| Electromagnetic Stirring | Natural agitation of molten pool | Atomic-level element mixing |

| Multiple Remelting | Minimum 3 cycles + flipping | Eliminates compositional segregation |

Elevate Your Materials Synthesis with KINTEK

Precise alloy preparation requires equipment that can handle extreme temperatures while maintaining absolute purity. KINTEK provides industry-leading Vacuum-arc, Muffle, Tube, and CVD systems designed to solve the most complex metallurgical challenges.

Whether you are synthesizing reactive titanium alloys or performing critical phase stabilization, our expert R&D and manufacturing teams offer customizable high-temperature solutions tailored to your unique lab requirements.

Ready to achieve superior homogeneity in your research? Contact us today to discuss your furnace needs.

References

- Nthabiseng Moshokoa, Maje Phasha. Influence of intermetallic phase (TiFe) on the microstructural evolution and mechanical properties of as-cast and quenched Ti–Mo–Fe alloys. DOI: 10.1038/s41598-024-60894-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What role does a Vacuum Induction Melting furnace play in the production of high-aluminum nickel-based superalloys?

- What are the two main types of graphite crucibles used in induction furnaces? Clay-Graphite vs. Silicon Carbide

- What are the key components of an induction-heated vacuum furnace? Uncover the Systems for Pure Melting

- What are the technical advantages of using a Vacuum Induction Melting furnace in the development of advanced packaging steel?

- What are the different types of vacuum melting furnaces and how do they compare? Choose the Right Furnace for Your Metallurgical Needs

- What are the key advantages of using induction furnaces for metal casting? Boost Efficiency and Quality in Your Foundry

- Why can a high vacuum cause process failure in Nb-MASC alloys? Prevent Critical Loss of Volatile Elements

- Why use a vertical induction furnace for magnesium smelting? Achieve Continuous, High-Efficiency Production