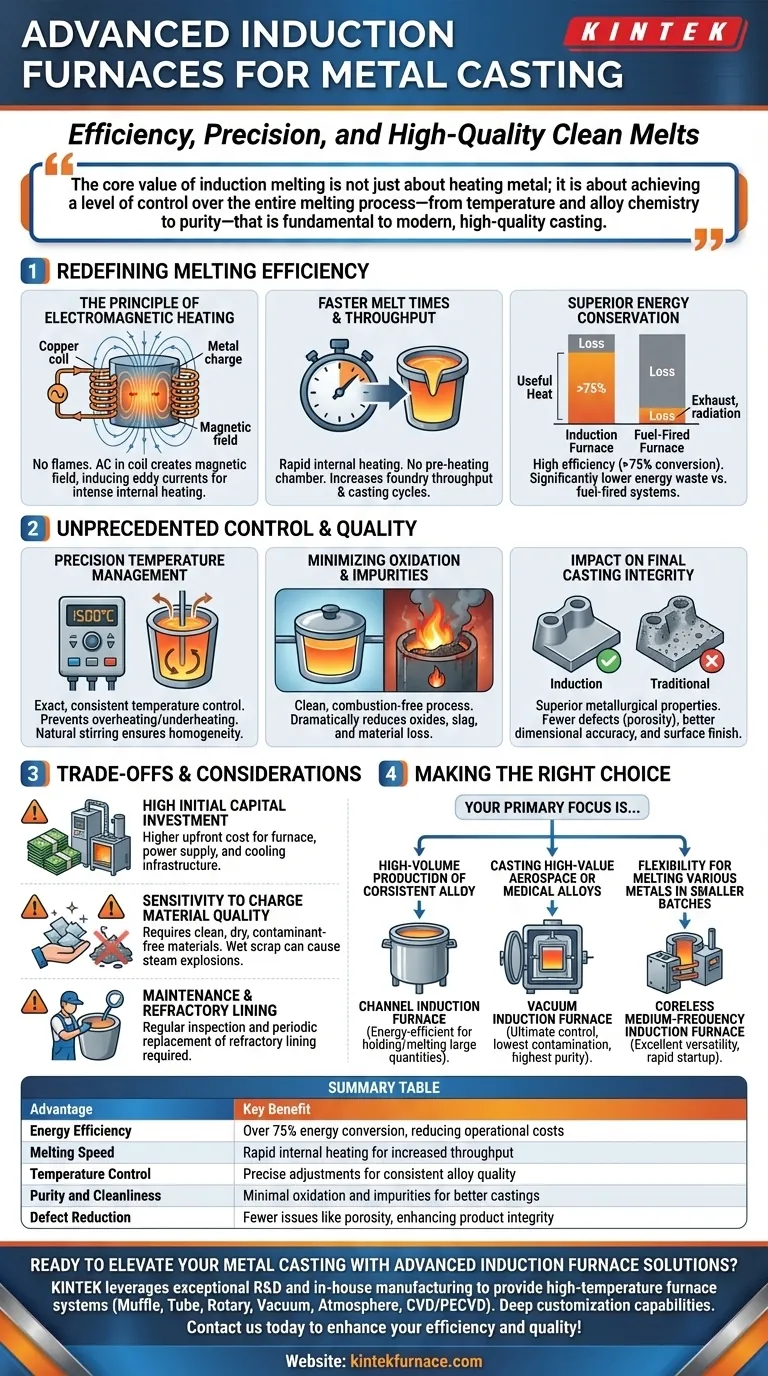

The primary advantages of induction furnaces for metal casting are their exceptional efficiency, precision control, and ability to produce high-quality, clean melts. This technology leverages electromagnetic heating to melt metal faster and with less energy consumption than traditional fuel-fired methods, resulting in significant operational cost savings and superior final product integrity.

The core value of induction melting is not just about heating metal; it is about achieving a level of control over the entire melting process—from temperature and alloy chemistry to purity—that is fundamental to modern, high-quality casting.

How Induction Furnaces Redefine Melting Efficiency

The efficiency of an induction furnace stems directly from its unique heating method, which is fundamentally different from conventional combustion-based systems.

The Principle of Electromagnetic Heating

An induction furnace operates without flames or external heating elements. Instead, a powerful alternating current is passed through a copper coil, creating a strong magnetic field.

This magnetic field induces powerful electrical currents, known as eddy currents, directly within the metal charge itself. The metal's natural electrical resistance causes these currents to generate intense, rapid heat, melting it from the inside out.

Faster Melt Times and Throughput

Because heat is generated directly within the metal, the melting process is extremely fast and efficient. There is no need to first heat a chamber and then transfer that heat to the charge.

This rapid melting capability significantly increases foundry throughput, allowing for more casting cycles per shift compared to slower, conventional methods.

Superior Energy Conservation

Induction furnaces boast high energy efficiency, often converting over 75% of their electrical energy directly into useful heat in the metal.

This is a stark contrast to fuel-fired furnaces, where a substantial amount of energy is lost to the environment through exhaust gases and heat radiation from the furnace walls.

Achieving Unprecedented Control and Quality

The benefits of induction go beyond speed and efficiency. The process provides a level of control that directly translates to higher-quality castings.

Precision Temperature Management

Induction systems allow for exact and consistent temperature control. The power input can be adjusted instantly to maintain the molten bath at the precise temperature required for a specific alloy and casting process.

This prevents overheating, which can burn off valuable alloying elements, and underheating, which can lead to casting defects. The electromagnetic field also creates a natural stirring action, ensuring a homogenous temperature and chemical composition throughout the melt.

Minimizing Oxidation and Impurities

Since there is no combustion, the process is inherently cleaner. The melt is not exposed to the byproducts of burning fuel, such as sulfur or other contaminants.

This clean melting environment dramatically reduces the formation of oxides and slag, leading to less material loss and a purer final metal for casting.

The Impact on Final Casting Integrity

The combination of precise temperature control and a clean melt environment results in castings with superior metallurgical properties.

Foundries experience fewer defects like porosity, enhanced dimensional accuracy, and a better surface finish, which often reduces the need for extensive and costly secondary machining operations.

Understanding the Trade-offs and Considerations

While highly advantageous, induction technology is not a universal solution. A clear understanding of its requirements is essential for successful implementation.

High Initial Capital Investment

The primary barrier to adoption is cost. Induction furnace systems, including their power supplies and cooling infrastructure, represent a significantly higher upfront capital investment compared to simple fuel-fired furnaces.

Sensitivity to Charge Material Quality

The performance of an induction furnace is sensitive to the quality of the scrap or charge material used. Materials must be clean, dry, and free of non-metallic contaminants to ensure a safe, efficient melt. Wet or oily scrap can cause dangerous steam explosions.

Maintenance and Refractory Lining

The refractory lining that contains the molten metal is a critical component that requires regular inspection and periodic replacement. The longevity of this lining is a key operational factor, and its maintenance requires specialized knowledge.

Making the Right Choice for Your Operation

The decision to use an induction furnace should be driven by your specific production goals, the types of metals you work with, and your quality requirements.

- If your primary focus is high-volume production of a consistent alloy: A channel induction furnace is often the most energy-efficient choice for holding and melting large quantities.

- If your primary focus is casting high-value aerospace or medical alloys: A vacuum induction furnace provides the ultimate control over atmospheric contamination, ensuring the highest possible purity.

- If your primary focus is flexibility for melting various metals in smaller batches: A coreless, medium-frequency induction furnace offers excellent versatility and rapid startup for diverse jobbing foundry work.

Ultimately, investing in induction technology is a strategic decision that elevates control over the most critical variable in casting: the quality of your molten metal.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Energy Efficiency | Over 75% energy conversion, reducing operational costs |

| Melting Speed | Rapid internal heating for increased throughput |

| Temperature Control | Precise adjustments for consistent alloy quality |

| Purity and Cleanliness | Minimal oxidation and impurities for better castings |

| Defect Reduction | Fewer issues like porosity, enhancing product integrity |

Ready to elevate your metal casting with advanced induction furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnace systems tailored for industries like aerospace, automotive, and medical. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Contact us today to discuss how we can enhance your efficiency and quality!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries