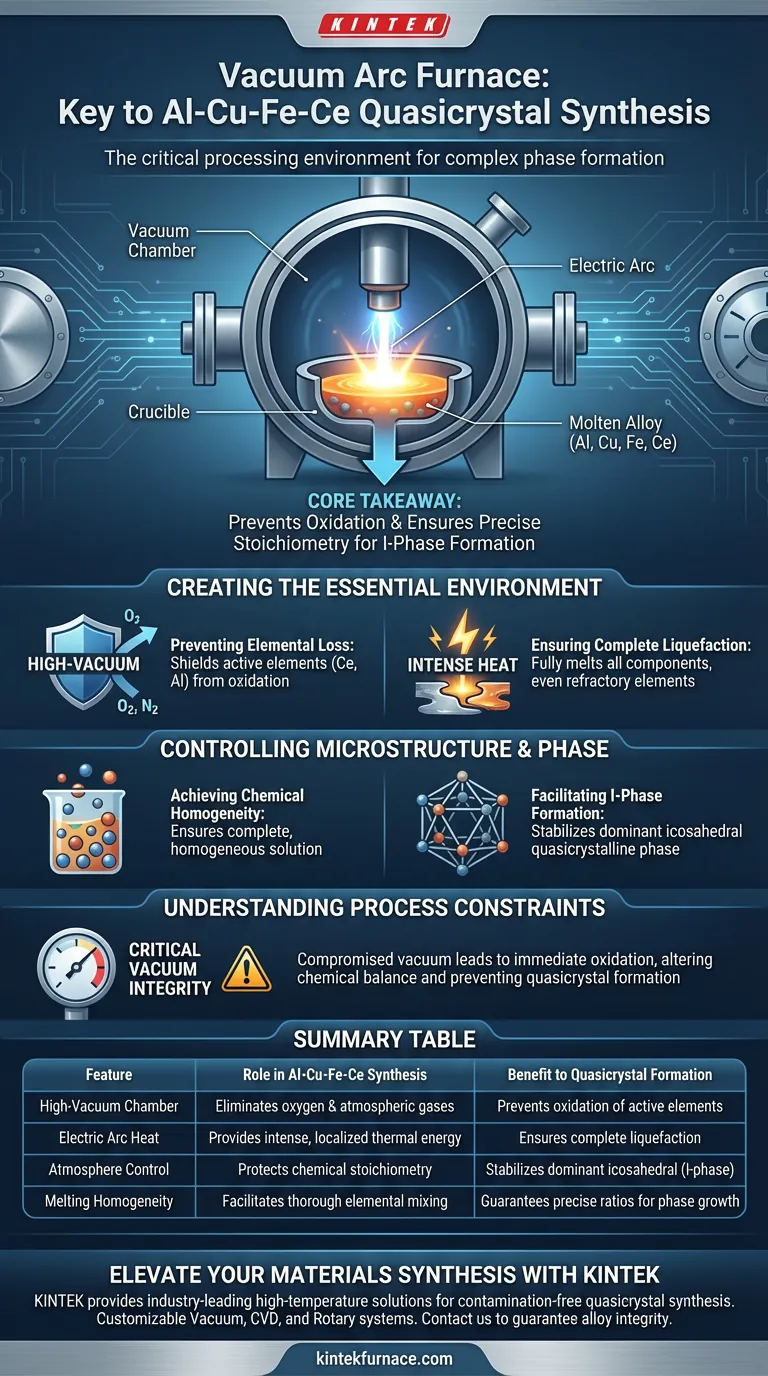

The Vacuum Arc Furnace acts as the critical processing environment for synthesizing Al-Cu-Fe-Ce quasicrystal master alloys. It utilizes intense electric arc heat within a high-vacuum chamber to melt reactive components, preventing oxidation while ensuring the precise chemical stoichiometry required for complex phase formation.

Core Takeaway The synthesis of quasicrystals is highly sensitive to impurities and compositional deviations. The Vacuum Arc Furnace solves this by eliminating oxygen during the melt, guaranteeing the stability of active elements and creating the specific conditions necessary to form the dominant icosahedral (I-phase) structure.

Creating the Essential Environment

Preventing Elemental Loss

The primary role of the furnace is to maintain a high-vacuum environment. This is non-negotiable for this specific alloy system.

Alloys containing active metallic elements (such as Cerium and Aluminum) are prone to rapid oxidation at elevated temperatures. The vacuum shield prevents these elements from reacting with air, ensuring they remain in the melt rather than becoming oxide slag.

Ensuring Complete Liquefaction

The furnace generates intense heat via an electric arc.

This thermal energy is sufficient to fully melt components with varying melting points. It ensures that even the most refractory elements in the mix are brought to a liquid state, which is the first step toward creating a unified alloy.

Controlling Microstructure and Phase

Achieving Chemical Homogeneity

Melting is not enough; the components must be thoroughly mixed.

The arc melting process ensures that all elements are fully integrated into a homogeneous solution. This precise chemical composition is vital because quasicrystals require exact stoichiometric ratios to form correctly.

Facilitating I-Phase Formation

The ultimate goal of using this furnace is to stabilize the dominant I-phase (icosahedral quasicrystalline phase).

By controlling the atmosphere and ensuring chemical uniformity, the furnace establishes the thermodynamic conditions required for this unique atomic structure to nucleate and grow. Without this controlled environment, the formation of the quasicrystal phase would likely be disrupted by impurities or segregation.

Understanding the Process Constraints

The Sensitivity of Composition

While the furnace is powerful, the process relies heavily on the maintenance of the vacuum.

If the vacuum integrity is compromised, the active elements will oxidize immediately. This alters the chemical balance of the master alloy, making it impossible to achieve the target quasicrystalline structure. The equipment does not just "melt" metal; it actively protects the recipe.

Making the Right Choice for Your Goal

To maximize the quality of your Al-Cu-Fe-Ce master alloys, consider these specific operational focuses:

- If your primary focus is Purity: Prioritize the depth of the vacuum before initiating the arc to strictly prevent the oxidation of active elements like Cerium.

- If your primary focus is Phase Stability: Ensure the melt is held under the arc long enough to guarantee complete mixing, which is the prerequisite for the dominant I-phase formation.

Success in synthesizing quasicrystals depends entirely on maintaining a contamination-free environment that preserves the precise stoichiometry of the melt.

Summary Table:

| Feature | Role in Al-Cu-Fe-Ce Synthesis | Benefit to Quasicrystal Formation |

|---|---|---|

| High-Vacuum Chamber | Eliminates oxygen and atmospheric gases | Prevents oxidation of active elements like Cerium |

| Electric Arc Heat | Provides intense, localized thermal energy | Ensures complete liquefaction of refractory components |

| Atmosphere Control | Protects chemical stoichiometry | Stabilizes the dominant icosahedral (I-phase) |

| Melting Homogeneity | Facilitates thorough elemental mixing | Guarantees the precise ratios required for phase growth |

Elevate Your Materials Synthesis with KINTEK

Precise control over stoichiometry and atmosphere is non-negotiable when synthesizing complex Al-Cu-Fe-Ce quasicrystals. KINTEK provides industry-leading high-temperature solutions—including Vacuum, CVD, and Rotary systems—engineered to eliminate contamination and ensure phase stability.

Backed by expert R&D and manufacturing, our furnaces are fully customizable to meet the unique demands of your advanced materials research. Contact KINTEK today to discover how our high-vacuum technology can guarantee the integrity of your master alloys.

Visual Guide

References

- Juan Wang, Zhong Yang. Microstructure and Properties of Al-Cu-Fe-Ce Quasicrystalline-Reinforced 6061 Aluminum Matrix Composites after Aging. DOI: 10.3390/coatings14030372

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What are the process advantages of cyclic vacuum annealing and oxidation? Maximize Carbon Chain Yield up to 48%

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- Why is a vacuum oven required for drying ZIF67/NiMoO4 composite materials? Protect Delicate Material Architecture

- What are the advantages of using a vacuum brazing furnace over other metal joining processes? Achieve Clean, Strong, and Distortion-Free Metal Joints

- What is unique about the heating mechanism of a Spark Plasma Sintering (SPS) furnace when preparing nanostructured h-BN ceramics? Achieve Ultra-Fast Densification and Suppress Grain Growth

- Why is a vacuum heat treatment furnace required for IN718-CuCrZr? Maximize Bimetallic Bond Strength

- What are the key applications of high vacuum furnaces? Unlock Purity and Performance in Critical Industries

- Why is a laboratory vacuum oven necessary for drying degraded LTGP samples? Ensure Pure Surface Analysis Results