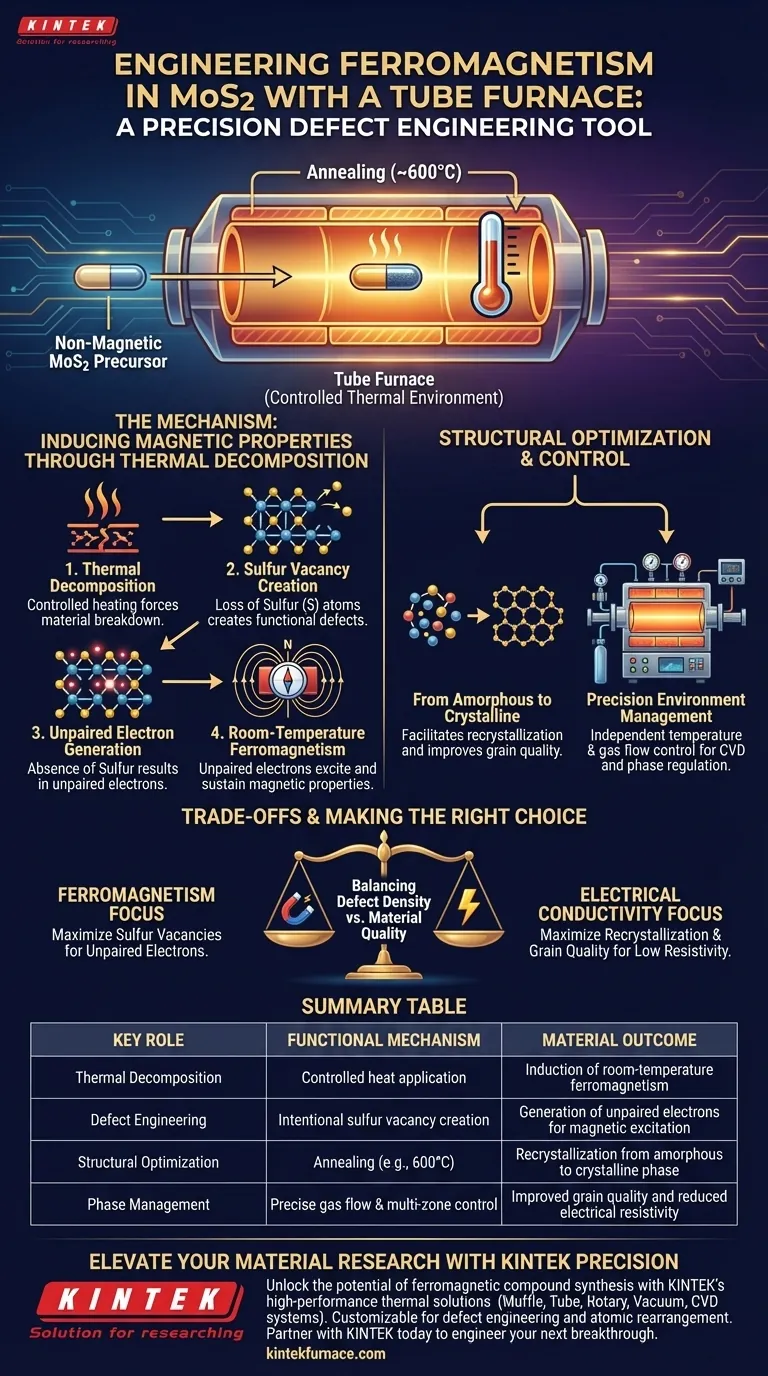

In the preparation of ferromagnetic Molybdenum Disulfide (MoS2), the Tube Furnace acts as a precision instrument for defect engineering. Its primary function is to provide a strictly controlled thermal environment that induces specific structural changes—specifically sulfur vacancies—necessary to activate magnetic properties in an otherwise non-magnetic material.

Core Insight: The Tube Furnace does not simply heat the material; it acts as a catalyst for thermal decomposition. By annealing at specific temperatures, the furnace forces the loss of sulfur atoms, creating vacancies that generate unpaired electrons—the key source of room-temperature ferromagnetism in MoS2.

The Mechanism of Magnetic Induction

Inducing Thermal Decomposition

To synthesize ferromagnetic MoS2, the material must undergo a specific type of thermal treatment. The Tube Furnace creates an environment where thermal decomposition occurs in a controlled manner.

Creating Sulfur Vacancies

The heat applied by the furnace causes sulfur atoms to disassociate from the MoS2 lattice. This process intentionally creates sulfur vacancies, which are essentially missing atoms within the crystal structure.

Generating Unpaired Electrons

These sulfur vacancies are not merely structural flaws; they are functionally active defects. The absence of sulfur atoms results in unpaired electrons, which are physically required to excite and sustain room-temperature ferromagnetism.

Structural Optimization and Control

From Amorphous to Crystalline

Beyond creating magnetic defects, the Tube Furnace is essential for defining the material's structure. It facilitates the recrystallization of MoS2 thin films, transforming them from an amorphous or weakly crystalline state into a highly ordered structure.

Enhancing Atomic Arrangement

During the annealing process (often around 600°C), the furnace allows for significant atomic rearrangement. This improves the overall grain quality and phase stability of the compound.

Precision Environment Management

In advanced setups, such as Chemical Vapor Deposition (CVD), the furnace acts as a multi-zone vessel. It utilizes independent temperature controls and precise gas flow systems to regulate the decomposition of precursors and the phase of the resulting compound.

Understanding the Trade-offs

Defect Density vs. Material Quality

There is a delicate balance between creating defects for magnetism and maintaining structural integrity. While sulfur vacancies are necessary for ferromagnetism, an excess of defects can degrade the material's stability.

Resistivity and Crystallinity

While annealing generally improves electrical properties by reducing resistivity, the introduction of vacancies alters the electronic landscape. You must balance the need for high-quality crystallization with the need for the specific defects that drive magnetism.

Making the Right Choice for Your Goal

The Tube Furnace is a versatile tool, but your operational parameters must align with your specific end-goal for the MoS2 material.

- If your primary focus is Inducing Ferromagnetism: Prioritize thermal decomposition parameters that maximize the formation of sulfur vacancies to generate unpaired electrons.

- If your primary focus is Electrical Conductivity: Focus on annealing regimes (e.g., around 600°C) that maximize recrystallization and grain quality to reduce resistivity.

Success relies on using the Tube Furnace not just to heat the sample, but to precisely engineer the atomic defects that dictate the material's behavior.

Summary Table:

| Key Role | Functional Mechanism | Material Outcome |

|---|---|---|

| Thermal Decomposition | Controlled heat application | Induction of room-temperature ferromagnetism |

| Defect Engineering | Intentional sulfur vacancy creation | Generation of unpaired electrons for magnetic excitation |

| Structural Optimization | Annealing (e.g., 600°C) | Recrystallization from amorphous to crystalline phase |

| Phase Management | Precise gas flow & multi-zone control | Improved grain quality and reduced electrical resistivity |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your ferromagnetic compound synthesis with KINTEK’s high-performance thermal solutions. Backed by expert R&D and world-class manufacturing, we provide a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of your defect engineering and atomic rearrangement processes.

Whether you are focusing on maximizing sulfur vacancies for magnetism or optimizing grain quality for conductivity, our precision-engineered furnaces deliver the uniform heating and atmosphere control your research requires. Partner with KINTEK today to engineer your next breakthrough—Contact us now!

Visual Guide

References

- Chang-Soo Park, Deuk Young Kim. Strong Room-Temperature Ferromagnetism of MoS2 Compound Produced by Defect Generation. DOI: 10.3390/nano14040334

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- Why must catalysts undergo reduction in a tube furnace? Master Your Furfural Hydrogenation Preparation

- How is a tube high-temperature furnace utilized in the preparation of NiSA-O/Mo2C catalysts? Expert Synthesis Guide

- How does thermal treatment in a tube furnace improve biomass films? Enhance Heat Management via Graphitization

- What factors should be considered when choosing a vertical tube furnace? Key Selection Criteria for Optimal Performance

- Why is a continuous nitrogen flow required in a closed tube furnace during the solid-phase synthesis of LiMnO2 precursors?

- What role does automation play in horizontal electric furnaces? Boost Precision and Efficiency in Thermal Processing

- What are the key features of a modern tube furnace? Precision, Control, and Versatility for Advanced Labs

- What role does a tube furnace play in producing activated carbon? Master Walnut Shell Activation for High Adsorption