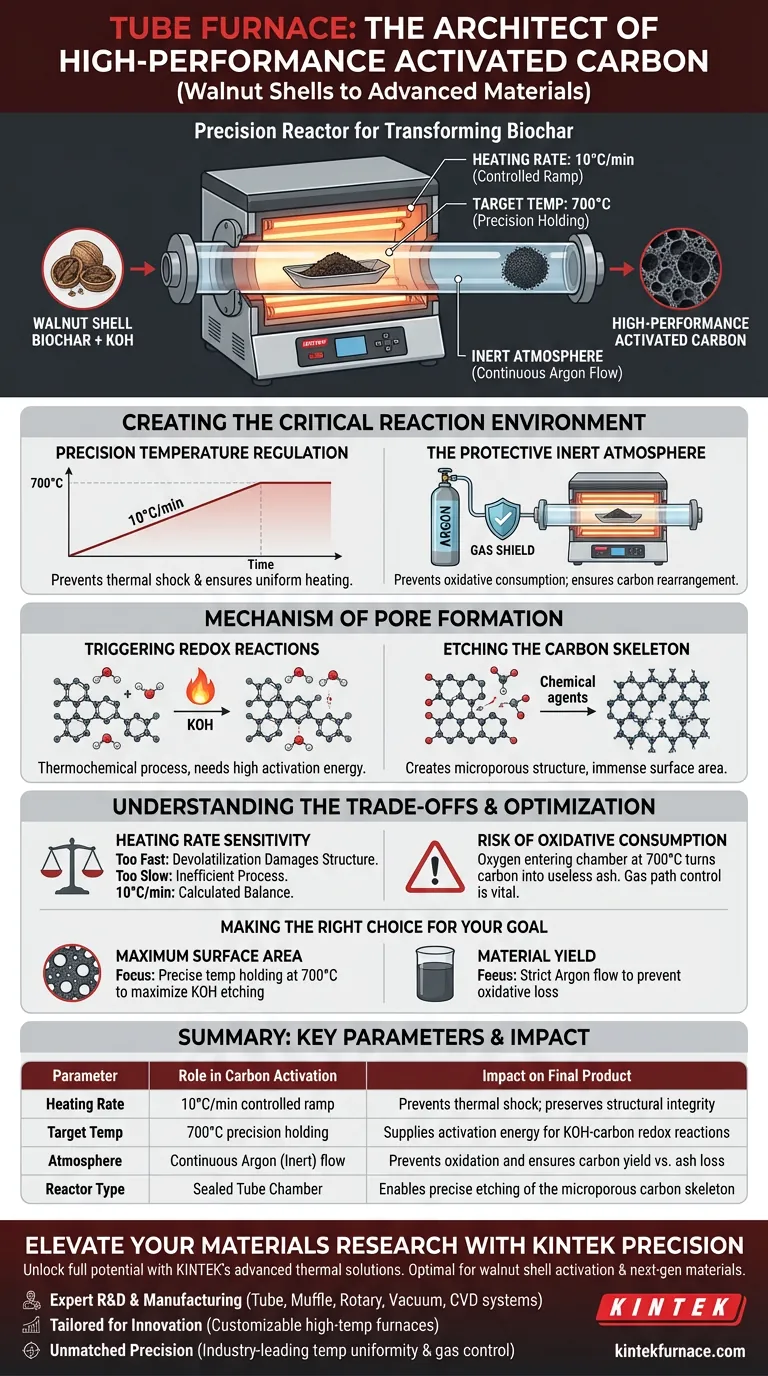

A tube furnace serves as the precision reactor necessary to convert walnut shell biochar into high-performance activated carbon. It creates a strictly controlled thermal environment—specifically heating at a rate of 10°C per minute to a target of 700°C under argon gas—to facilitate the critical chemical reaction between the biochar and the activating agent, typically potassium hydroxide (KOH).

The tube furnace is not merely a heat source; it is the architect of the material's internal structure. By maintaining a precise, oxygen-free thermal field, it drives the specific redox reactions that etch the carbon skeleton, directly determining the final surface area and adsorption efficiency.

Creating the Critical Reaction Environment

The production of high-performance carbon requires conditions that a standard oven cannot provide. The tube furnace creates a highly specific "thermal field" that governs the transformation of the walnut shell precursor.

Precision Temperature Regulation

The furnace must ramp up temperature at a controlled rate, such as 10 degrees Celsius per minute. It acts as a governor for the reaction speed.

This slow, steady rise prevents thermal shock and ensures uniform heating throughout the material. Once the target temperature (typically 700°C) is reached, the furnace maintains it with high precision to sustain the reaction.

The Protective Inert Atmosphere

High-performance carbon cannot be produced in the presence of air. The tube furnace utilizes a sealed chamber to maintain a continuous flow of inert gas, such as argon.

This "gas shield" prevents the carbon from burning away (oxidizing) at high temperatures. It ensures that the carbon atoms are rearranged rather than destroyed.

Mechanism of Pore Formation

The defining characteristic of "high-performance" activated carbon is its microporous structure. The tube furnace is the tool that physically enables the chemistry required to create these pores.

Triggering Redox Reactions

Inside the furnace, the high heat triggers a chemical redox reaction between the walnut shell biochar and the impregnated potassium hydroxide (KOH).

This is a thermochemical process that cannot occur efficiently at lower temperatures or with uneven heat. The furnace supplies the activation energy required to initiate this specific chemical interchange.

Etching the Carbon Skeleton

As the reaction proceeds, the chemical agents "etch" the carbon framework. This process removes specific carbon atoms from the lattice.

This etching creates a vast network of micropores within the biochar. These pores are what give the final product its immense surface area and superior adsorption capabilities.

Understanding the Trade-offs

While the tube furnace is the optimal tool for this process, improper operation can lead to material failure. Understanding these variables is critical for consistent results.

Sensitivity to Heating Rates

The heating rate is a significant variable. If the temperature rises too quickly, the devolatilization process may become violent, damaging the pore structure.

Conversely, if the heating is too slow, the process becomes inefficient. The 10°C/min rate is a calculated balance to maximize structural integrity.

The Risk of Oxidative Consumption

The integrity of the inert atmosphere is non-negotiable. If the furnace seal fails or the gas flow is interrupted, oxygen will enter the chamber.

At 700°C, oxygen causes "oxidative consumption," effectively turning your high-value activated carbon into useless ash. The gas path control system is as vital as the heating elements.

Making the Right Choice for Your Goal

The way you operate the tube furnace dictates the specific properties of the final walnut shell activated carbon.

- If your primary focus is Maximum Surface Area: Prioritize precise temperature holding at 700°C to maximize the KOH etching effect without collapsing the pore structure.

- If your primary focus is Material Yield: Strict control of the argon flow is essential to prevent oxidative loss of the carbon substrate during the high-heat phase.

The tube furnace transforms raw potential into performance by balancing thermal energy with chemical precision.

Summary Table:

| Parameter | Role in Carbon Activation | Impact on Final Product |

|---|---|---|

| Heating Rate | 10°C/min controlled ramp | Prevents thermal shock; preserves structural integrity |

| Target Temp | 700°C precision holding | Supplies activation energy for KOH-carbon redox reactions |

| Atmosphere | Continuous Argon (Inert) flow | Prevents oxidation and ensures carbon yield vs. ash loss |

| Reactor Type | Sealed Tube Chamber | Enables precise etching of the microporous carbon skeleton |

Elevate Your Materials Research with KINTEK Precision

Unlock the full potential of your biomass precursors with KINTEK’s advanced thermal solutions. Whether you are optimizing walnut shell activation or developing next-generation energy storage materials, our systems provide the stability and control required for world-class results.

Why Choose KINTEK?

- Expert R&D & Manufacturing: High-performance Tube, Muffle, Rotary, Vacuum, and CVD systems.

- Tailored for Innovation: Fully customizable lab high-temp furnaces designed for your unique research needs.

- Unmatched Precision: Industry-leading temperature uniformity and gas path control to prevent oxidative loss.

Ready to transform raw potential into high-performance carbon? Contact our technical experts today to find the perfect furnace for your laboratory.

Visual Guide

References

- Zitong Zhuang, Hui Jin. Preparation of biochar adsorption material from walnut shell by supercritical CO2 pretreatment. DOI: 10.1007/s42773-024-00302-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is heat transferred to the material inside the tube furnace? Master the Three-Stage Process for Precise Heating

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How can the uniform length of a tube furnace be improved? Boost Temperature Uniformity with Proven Methods

- How does the working temperature range affect the choice of a tube furnace? Match Your Lab's Thermal Needs for Precision and Cost-Efficiency

- What role does an industrial-grade tube furnace play in Fe-P-NC catalyst pyrolysis? Precision Heating for Fe-P-NC Synthesis

- How is a laboratory tube furnace used in materials science research? Unlock Precision in Material Synthesis and Heat Treatment

- What conditions does a tube furnace provide for post-ion-implantation? Achieve Precise Microstructural Repair

- How do sealed flanges improve oxygen annealing for superconducting joints? Enhance Purity and Precision