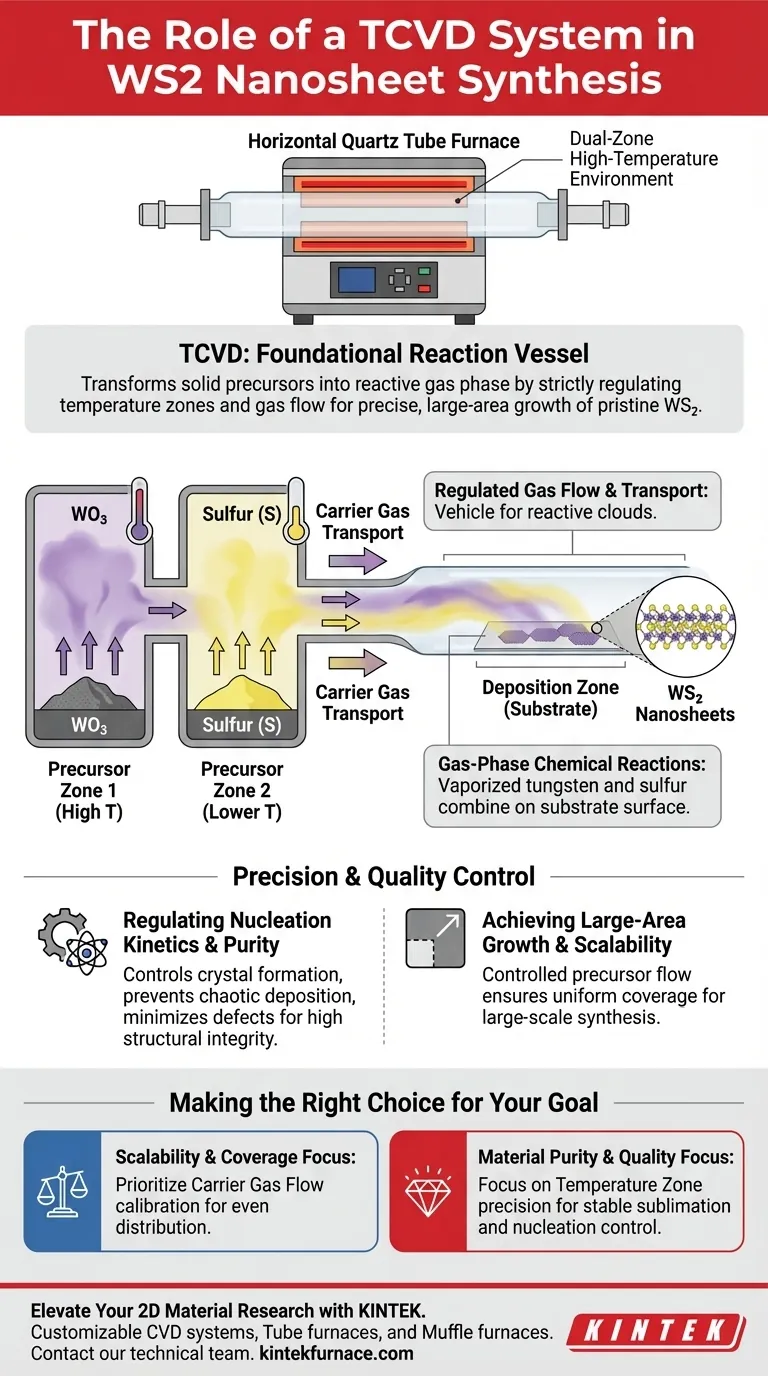

A Thermal Chemical Vapor Deposition (TCVD) system serves as the foundational reaction vessel for synthesizing Tungsten Disulfide (WS2) nanosheets. It orchestrates the growth process by creating a dual-zone high-temperature environment within a horizontal quartz tube furnace, where solid precursors—Sulfur (S) and Tungsten Trioxide (WO3)—are sublimated and transported by carrier gases to deposit as high-quality, two-dimensional layers on a substrate.

The TCVD system transforms solid chemical precursors into a reactive gas phase by strictly regulating temperature zones and gas flow, enabling the precise, large-area growth of pristine WS2 structures.

The Mechanics of the Reaction Environment

The Horizontal Quartz Tube Setup

The core of the TCVD system is a horizontal quartz tube furnace. This tube acts as the reaction chamber, providing a clean, isolated environment necessary for high-purity synthesis.

Creating Specific Temperature Zones

Unlike simple heating elements, the TCVD system is designed to manage separate temperature zones. This is critical because the precursors used for WS2 synthesis have vastly different thermal requirements.

Thermal Separation

The system allows for the independent heating of Tungsten Trioxide (WO3) and Sulfur (S). This ensures that both materials reach their specific sublimation points at the exact right moment to facilitate the reaction.

The Role of Precursors and Transport

Sublimation of Precursors

The primary function of the heat is sublimation. The system converts solid WO3 and S into a vapor state, releasing them as reactive gases within the tube.

Carrier Gas Transport

Once the precursors are vaporized, the system utilizes carrier gases to move them down the tube. These gases act as a vehicle, transporting the reactive clouds from the source zones toward the target substrate.

Gas-Phase Chemical Reactions

Deposition occurs through a gas-phase chemical reaction. The vaporized tungsten and sulfur combine on the surface of the substrate to form the desired WS2 nanosheets.

Precision and Quality Control

Regulating Nucleation Kinetics

By managing the furnace temperature and pressure, the system controls nucleation kinetics. This dictates how the crystals begin to form and grow, preventing random or chaotic deposition.

Achieving Large-Area Growth

The controlled flow of precursors ensures uniform coverage. This capability allows for the synthesis of large-area materials rather than just isolated microscopic clusters.

High-Quality Structure

The precise environment minimizes defects. The result is the formation of high-quality, two-dimensional materials with high structural integrity.

Understanding the Trade-offs

Complexity of Multi-Zone Control

Operating a TCVD system requires balancing multiple variables simultaneously. If the temperature in the sulfur zone fluctuates even slightly, it can alter the stoichiometry of the final product, leading to poor quality WS2.

Sensitivity to Gas Flow Rates

The carrier gas flow is a double-edged sword. While necessary for transport, an aggressive flow rate can blow the precursors past the substrate before they deposit, while a flow that is too slow may cause uneven thickness or premature deposition.

Making the Right Choice for Your Goal

To maximize the effectiveness of a TCVD system for WS2 synthesis, you must align the system settings with your specific objectives.

- If your primary focus is Scalability and Coverage: Prioritize the calibration of carrier gas flow rates to ensure the vaporized precursors are distributed evenly across the entire length of the substrate.

- If your primary focus is Material Purity and Quality: Focus heavily on the precision of the temperature zones, ensuring the precursors sublime at stable rates to control nucleation kinetics effectively.

Success in WS2 synthesis relies not just on heating the materials, but on the precise orchestration of their transport and reaction.

Summary Table:

| Component/Process | Role in WS2 Synthesis |

|---|---|

| Horizontal Quartz Tube | Provides a clean, isolated environment for high-purity reaction. |

| Dual Temperature Zones | Independently regulates sublimation of Sulfur and Tungsten Trioxide. |

| Carrier Gas Flow | Transports vaporized precursors to the substrate for deposition. |

| Nucleation Kinetics | Controls crystal formation to ensure high structural integrity. |

| Substrate Deposition | Facilitates gas-phase reactions for large-area 2D material growth. |

Elevate Your 2D Material Research with KINTEK

Precise control over temperature zones and gas flow is non-negotiable for high-quality WS2 synthesis. Backed by expert R&D and world-class manufacturing, KINTEK provides industry-leading CVD systems, Tube furnaces, and Muffle furnaces—all fully customizable to meet your unique laboratory requirements.

Whether you are focusing on scalability or material purity, our systems deliver the stability your research demands. Contact our technical team today to discuss your specific needs and discover how our advanced thermal solutions can optimize your synthesis outcomes.

Visual Guide

References

- Mohammad Shahbazi, Ramin Mohammadkhani. High performance in the DC sputtering-fabricated Au/WS2 optoelectronic device. DOI: 10.1038/s41598-025-87873-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- Why is precise temperature control of the precursor delivery system essential in CVD for hollow silica particles?

- What is the role of the Quartz Tube CVD Furnace in the synthesis of 2D In2Se3 nanosheets? Expert Synthesis Guide

- What role does a quartz tube reaction chamber play in CVD synthesis? Ensuring Purity in 2D TMD Growth

- What is Ultraviolet-activated Chemical Vapor Deposition (UVCVD)? Enable Low-Temp, High-Quality Coatings for Sensitive Materials

- How does PVD differ from CVD? A Guide to Choosing the Right Thin-Film Coating Process

- What protective functions does a circulating water cooling system provide during CVD? Secure Vacuum Integrity Today

- What are the applications of CVD in the automotive industry? Boost Vehicle Performance with Advanced Coatings

- What are the advantages of using Chemical Vapor Deposition? Achieve High-Purity, Uniform Thin Films for Your Applications