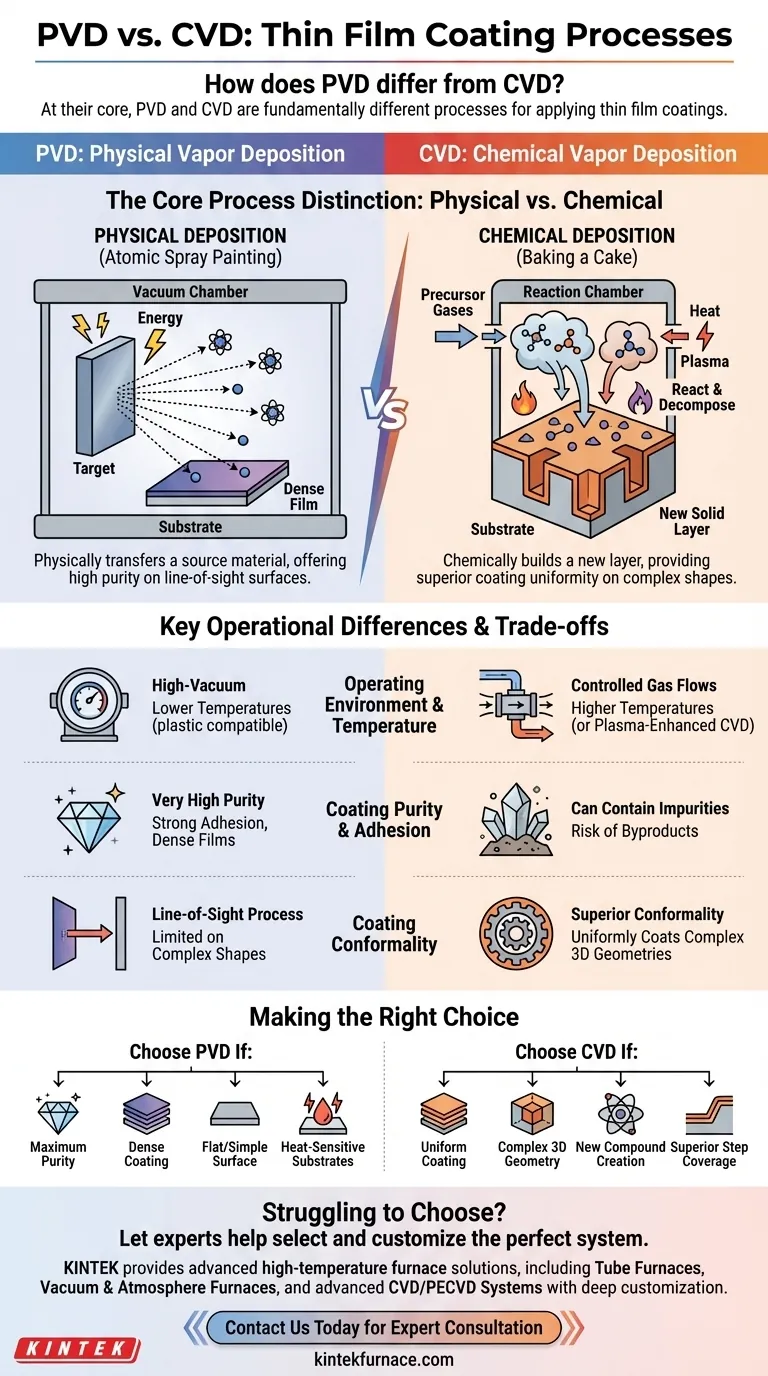

At their core, PVD and CVD are fundamentally different processes for applying thin film coatings. Physical Vapor Deposition (PVD) is a physical process that takes a solid material, vaporizes it in a vacuum, and deposits it atom-by-atom onto a substrate. Chemical Vapor Deposition (CVD), by contrast, is a chemical process where precursor gases react on the substrate's surface to grow an entirely new solid layer.

The choice between PVD and CVD is not about which is "better," but which process mechanics align with your end goal. PVD physically transfers a source material, offering high purity on line-of-sight surfaces, while CVD chemically builds a new layer, providing superior coating uniformity on complex shapes.

The Core Process Distinction: Physical vs. Chemical

Understanding the mechanism is the first step to choosing the right technology. The names themselves—Physical vs. Chemical—reveal the fundamental operational difference.

PVD: Physical Deposition Explained

PVD works by bombarding a solid source material, known as a target, with energy inside a high-vacuum chamber. This energy dislodges atoms or molecules from the target.

These dislodged particles travel in a straight line and condense on the cooler substrate, forming a thin, dense film. Think of it as an atomic-scale spray painting process, where the paint particles are atoms of the source material.

CVD: Chemical Vapor Deposition Explained

CVD introduces volatile precursor gases into a reaction chamber containing the substrate. These gases are not the final coating material.

Instead, energy—typically heat or plasma—is applied, causing the gases to react and decompose on the substrate's surface. This chemical reaction forms a new solid material as a film. It is less like painting and more like baking a cake, where raw ingredients (gases) are transformed by heat into a new solid (the coating).

Key Operational Differences

The physical versus chemical nature of these processes leads to significant practical differences in temperature, environment, and the final characteristics of the coating.

Operating Environment and Temperature

PVD is defined by its high-vacuum environment, which is necessary to allow atoms to travel from the target to the substrate without colliding with air molecules.

CVD processes operate with controlled gas flows and pressures. While traditional CVD requires very high temperatures to initiate the chemical reactions, modern variants like Plasma-Enhanced CVD (PECVD) can operate at much lower temperatures.

Coating Purity and Adhesion

PVD generally produces films of very high purity because it is simply transplanting the source material. The resulting coatings are also often very dense and exhibit strong adhesion due to the energetic impact of the atoms striking the surface.

CVD films can sometimes contain impurities from unreacted precursor gases or chemical byproducts that get trapped in the growing layer.

Coating Conformality

This is a critical point of divergence. CVD offers superior conformality, meaning it can uniformly coat complex, three-dimensional shapes with high aspect ratios. The precursor gases can flow into and react within intricate geometries.

PVD is a line-of-sight process. Surfaces that are not directly facing the source target will receive little to no coating, making it challenging to coat complex parts uniformly without sophisticated rotation and manipulation.

Understanding the Trade-offs

Neither technology is a universal solution. The strength of one is often the weakness of the other, creating a clear set of trade-offs for engineers to consider.

The PVD Compromise: Geometry Limitations

PVD's direct, line-of-sight transfer provides excellent control and purity for flat or simple surfaces. However, this becomes a significant limitation for parts with undercuts, deep trenches, or internal channels.

The CVD Compromise: Process Complexity and Impurities

CVD's primary advantage is its excellent conformality. The trade-off is a more complex process that often involves hazardous precursor gases and requires precise control over temperature and pressure to manage reaction rates. The chemical nature of the process also carries an inherent risk of incorporating unwanted byproducts into the final film.

Material and Substrate Compatibility

PVD can deposit a vast range of materials, including metals, alloys, and ceramics, as long as they can be made into a solid target. Because it can be a lower-temperature process, it is often compatible with more sensitive substrates like plastics.

CVD is limited by the availability of suitable volatile precursors for the desired material. Furthermore, the high temperatures of traditional CVD can damage or warp certain substrate materials.

Making the Right Choice for Your Application

Selecting the correct method requires matching the process characteristics to your primary objective.

- If your primary focus is maximum purity and density for a flat or simple surface: PVD is typically the superior choice due to its direct physical transfer mechanism.

- If your primary focus is uniformly coating a complex 3D geometry: CVD's ability for gases to reach all surfaces makes it the clear winner for conformality.

- If you are working with heat-sensitive substrates: A low-temperature PVD process or Plasma-Enhanced CVD (PECVD) should be your first consideration.

- If your goal is to create a new compound material on the surface that isn't easily sourced as a solid target: CVD's chemical reaction process is inherently designed for this task.

Understanding this fundamental distinction between physical transfer and chemical creation is the key to selecting the right tool for your specific engineering challenge.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Core Process | Physical transfer of a solid target material | Chemical reaction of precursor gases |

| Operating Environment | High vacuum | Controlled gas flow and pressure |

| Coating Conformality | Line-of-sight; limited on complex shapes | Excellent; uniformly coats complex 3D geometries |

| Typical Coating Purity | Very high | Can contain impurities from byproducts |

| Ideal For | Flat/simple surfaces, high purity, dense coatings | Complex shapes, superior step coverage, new compound creation |

Struggling to Choose Between PVD and CVD for Your Application?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and advanced CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental and coating requirements.

Let our experts help you select and customize the perfect system for your specific needs.

Contact us today to discuss your project and discover how KINTEK's solutions can enhance your research and development!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab