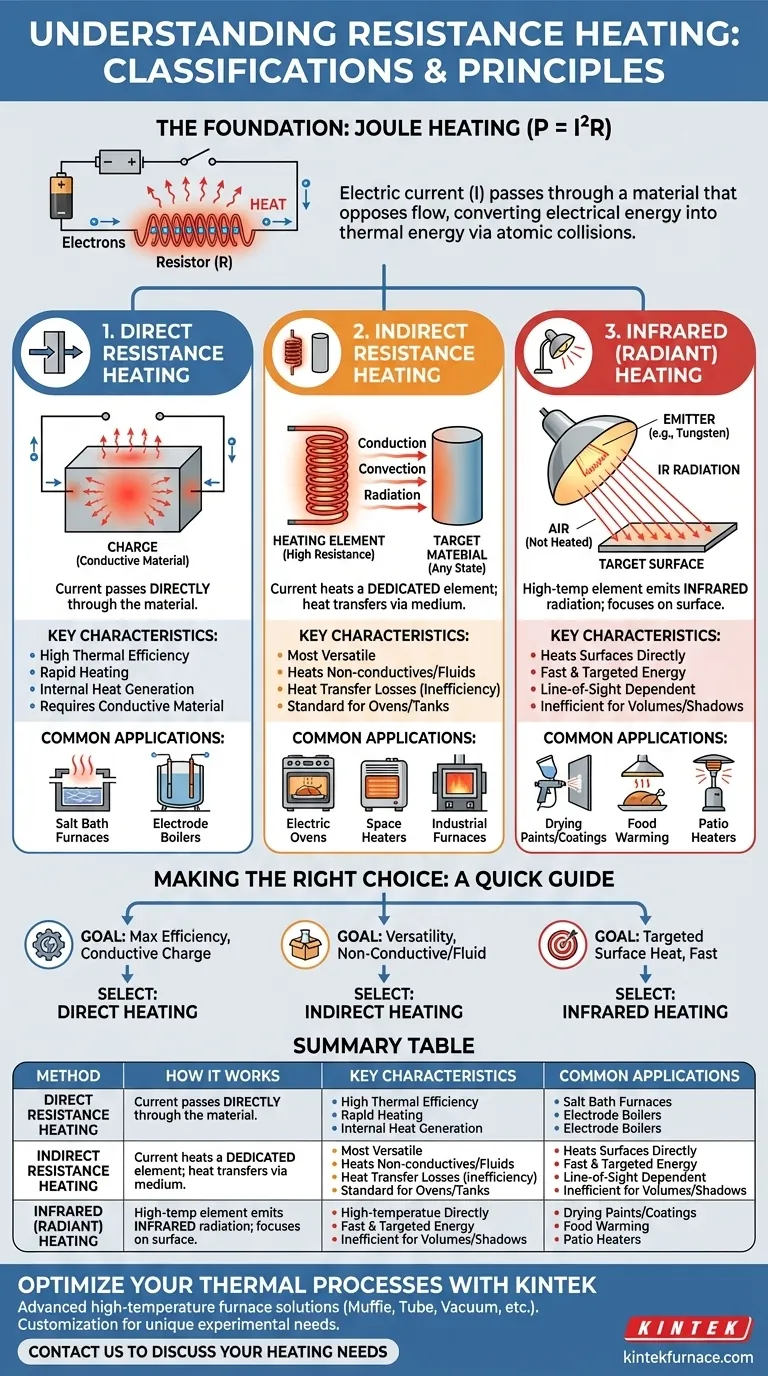

At its core, resistance heating is the process of generating heat by passing an electric current through a material that opposes its flow—a resistor. This conversion of electrical energy to thermal energy, governed by Joule's Law, is one of the most fundamental principles in electrical engineering. It is broadly classified into three distinct methods: direct resistance heating, indirect resistance heating, and infrared (or radiant) heating.

The distinction between the types of resistance heating is not merely academic. The choice of method depends entirely on what you are heating (the "charge"), how it can be heated, and the desired efficiency of the energy transfer.

The Fundamental Principle: Joule Heating

The Physics of Heat Generation

All resistance heating operates on the principle of Joule's First Law. This law states that the power converted into heat (P) is equal to the square of the current (I) multiplied by the resistance (R) of the material, or P = I²R.

Essentially, as electrons are forced through a resistive material, they collide with atoms, transferring their kinetic energy. This increased atomic vibration manifests as heat.

The Role of the Material

The effectiveness of a heating element is determined by its electrical resistance, its ability to withstand high temperatures without degrading, and its resistance to oxidation. This is why materials like nichrome (an alloy of nickel and chromium) are so common in heating elements.

1. Direct Resistance Heating: The Material is the Element

How It Works

In direct resistance heating, the electric current is passed directly through the material to be heated. The material itself acts as the resistor, causing heat to be generated internally.

This requires the material, or "charge," to be electrically conductive. Electrodes are placed in contact with the charge to complete the circuit.

Key Characteristics

The primary advantage of this method is its high thermal efficiency. Since the heat is generated within the substance, heat transfer losses to the surrounding environment are minimal. The heating process is also typically very rapid and allows for uniform temperature control.

Common Applications

This method is well-suited for specific industrial processes, such as salt bath furnaces for heat-treating metals or electrode water heaters and boilers where current is passed directly through the water.

2. Indirect Resistance Heating: Using a Dedicated Element

How It Works

Indirect resistance heating is the most common form. In this method, a current is passed through a high-resistance heating element, which becomes very hot.

This heat is then transferred to the material or space to be heated through a combination of conduction, convection, and radiation.

Key Characteristics

This method is incredibly versatile because the material being heated does not need to be electrically conductive. It is the standard for heating air, liquids in insulated tanks, and solids in ovens.

Common Applications

You encounter indirect resistance heating every day in devices like electric ovens, space heaters, toasters, and industrial process furnaces. The coiled or ribbon-like elements are typically made of nichrome.

3. Infrared (Radiant) Heating: Focused Energy Transfer

How It Works

Infrared heating is a specialized type of indirect heating. A heating element, often a tungsten filament, is heated to a very high temperature, causing it to emit a significant amount of electromagnetic energy in the infrared spectrum.

This energy travels in straight lines until it is absorbed by an object. Reflectors, often parabolic in shape, are used to direct this radiation precisely onto the target surface.

Key Characteristics

The defining feature of radiant heating is that it heats objects and surfaces directly, not the air in between. This allows for extremely fast and targeted energy transfer, making it highly efficient for specific tasks.

Common Applications

Infrared heating is ideal for applications like drying paints and coatings, food warming stations, and outdoor patio heaters. In all these cases, the goal is to heat a surface or person efficiently without wasting energy heating the surrounding air.

Understanding the Trade-offs

Efficiency vs. Control

Direct heating offers the highest potential efficiency because there are no intermediate transfer steps—the heat is born exactly where it's needed. However, it is limited to conductive materials and can be harder to control if the material's resistance changes with temperature.

Versatility vs. Losses

Indirect heating is the workhorse because it can heat virtually anything. Its primary trade-off is the inherent inefficiency of transferring heat from the element to the target. Heat is lost to the element's supports and the surrounding environment through convection and radiation.

Specificity vs. Environment

Infrared heating is unparalleled for surface heating, but it is a "line-of-sight" technology. It is inefficient for heating a volume of air or an object with a complex shape that creates shadows. The effectiveness depends entirely on the surface's ability to absorb infrared radiation.

Making the Right Choice for Your Goal

Selecting the proper heating method requires a clear understanding of your objective.

- If your primary focus is maximum thermal efficiency while heating a conductive substance: Direct resistance heating is the most effective approach as it generates heat within the material itself.

- If your primary focus is versatility for heating non-conductive materials, liquids, or air: Indirect resistance heating provides a robust and widely applicable solution.

- If your primary focus is rapidly heating surfaces or objects without affecting the surrounding air: Infrared (radiant) heating offers targeted, line-of-sight energy transfer for specialized applications.

Understanding these classifications moves beyond simple definitions, allowing you to select the precise tool for your specific thermal challenge.

Summary Table:

| Method | How It Works | Key Characteristics | Common Applications |

|---|---|---|---|

| Direct Resistance Heating | Current passes directly through the material to be heated | High thermal efficiency, rapid heating, requires conductive material | Salt bath furnaces, electrode water heaters |

| Indirect Resistance Heating | Current heats a dedicated element, transferring heat via conduction, convection, or radiation | Versatile, works with non-conductive materials, common in everyday devices | Electric ovens, space heaters, industrial furnaces |

| Infrared (Radiant) Heating | Element emits infrared radiation absorbed by objects | Heats surfaces directly, fast and targeted, line-of-sight dependent | Drying paints, food warming, patio heaters |

Optimize your thermal processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with reliable heating systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing efficiency and performance. Contact us today to discuss how we can support your specific heating needs!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films