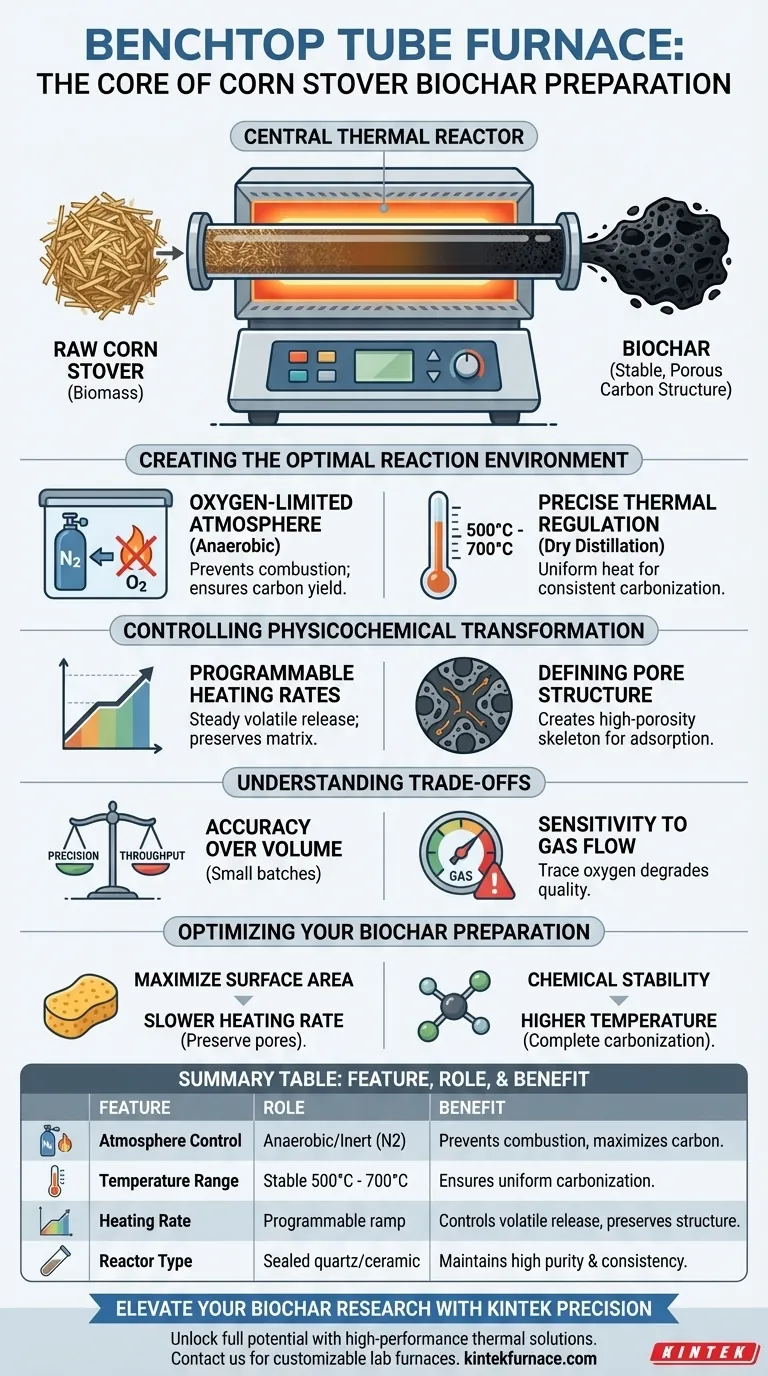

A benchtop tube furnace serves as the central thermal reactor for the laboratory-scale conversion of corn stover into biochar. It provides a sealed, strictly controlled environment where biomass undergoes dry distillation and carbonization under high temperatures (typically 500°C to 700°C) without the presence of oxygen.

Core Takeaway The tube furnace does not merely heat the material; it acts as a precision instrument for slow pyrolysis. By strictly regulating the atmosphere and heating rate, it transforms corn stover from raw agricultural waste into a stable, porous carbon structure with specific physicochemical properties defined by the researcher.

Creating the Optimal Reaction Environment

To convert corn stover into high-quality biochar, the equipment must prevent combustion while promoting thermal decomposition.

Oxygen-Limited Atmosphere

The most critical role of the tube furnace is to maintain an anaerobic or oxygen-limited environment.

By sealing the reaction zone and often utilizing a continuous flow of inert gas (such as nitrogen), the furnace prevents the corn stover from burning to ash. This ensures the carbon atoms remain in the solid structure rather than reacting with oxygen to form CO2.

Precise Thermal Regulation

The furnace facilitates thorough dry distillation by maintaining constant temperatures, specifically in the 500°C to 700°C range for corn stover.

This thermal stability is essential. It ensures that the heat distribution is uniform across the sample, leading to consistent carbonization throughout the batch rather than uneven pockets of unburnt biomass or over-processed ash.

Controlling Physicochemical Transformation

Beyond simple heating, the tube furnace allows for the engineering of the biochar's internal structure.

Regulating Heating Rates

A programmable tube furnace controls the speed at which the temperature rises.

Controlling this rate is vital for the steady release of volatile organic compounds. If the heating is too aggressive, the structure may collapse; a controlled rate preserves the matrix of the corn stover during the transition to biochar.

Defining Pore Structure

The furnace is responsible for creating the initial physicochemical structure of the biochar.

As the furnace drives off volatiles, it leaves behind a carbon skeleton. This process opens up primary channels and creates a high-porosity structure, which is the fundamental characteristic determining the biochar’s ability to adsorb substances later.

Understanding the Trade-offs

While the benchtop tube furnace is the standard for precision research, it creates specific limitations that researchers must acknowledge.

Throughput vs. Precision

These units are designed for accuracy, not volume.

While they offer exceptional control over parameters for characterization, they produce small batch sizes. They are ideal for determining the perfect recipe for corn stover biochar but cannot simulate the mass flow dynamics of industrial continuous pyrolysis reactors.

Sensitivity to Gas Flow

The quality of the "oxygen-free" environment is entirely dependent on the gas flow system.

Any fluctuation in the nitrogen purge or a leak in the tube seals can introduce oxygen. Even trace amounts of oxygen at 600°C can significantly degrade the yield and surface properties of the biochar, altering the experimental results.

Optimizing Your Biochar Preparation

To get the most out of your tube furnace experiments, align your settings with your specific research goals.

- If your primary focus is maximizing surface area: Program a slower heating rate to facilitate the gentle release of volatiles, preserving the delicate pore network.

- If your primary focus is chemical stability: Maintain the temperature at the higher end of the spectrum (closer to 700°C) to drive complete carbonization and increase the aromaticity of the structure.

The benchtop tube furnace provides the critical experimental control necessary to turn corn stover into a functional material with predictable, reproducible properties.

Summary Table:

| Feature | Role in Biochar Preparation | Research Benefit |

|---|---|---|

| Atmosphere Control | Provides anaerobic/inert environment (Nitrogen) | Prevents combustion to ash; maximizes carbon yield |

| Temperature Range | Stable heating between 500°C - 700°C | Ensures uniform carbonization and dry distillation |

| Heating Rate | Programmable ramp speeds | Controls volatile release and preserves pore structure |

| Reactor Type | Sealed quartz or ceramic tube | Maintains high purity and physicochemical consistency |

Elevate Your Biochar Research with KINTEK Precision

Unlock the full potential of your carbonization studies with KINTEK’s high-performance thermal solutions. Backed by expert R&D and manufacturing, we offer advanced Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of laboratory pyrolysis.

Whether you are preparing corn stover biochar or developing complex nanomaterials, our fully customizable lab furnaces provide the thermal stability and atmosphere control essential for reproducible results.

Ready to optimize your material synthesis? Contact KINTEK today to discuss your unique needs with our technical team!

Visual Guide

References

- Lijie Li, Mingsong Chen. Reduction Effect of Extra Biochar on PAHs Originating from Corn Stover Pyrolysis. DOI: 10.3390/molecules30214238

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a tube furnace achieve uniform thermal distribution? Master Precise Heat Control for Your Lab

- What role does a Tube Furnace play in the solution treatment of titanium alloys? Master Material Integrity.

- What are the main advantages of using a tube furnace in industrial and laboratory settings? Achieve Precise Temperature and Atmosphere Control

- What specific technological tasks does a high-temperature tube furnace perform? Testing Fiber Optic Sensor Reliability

- What role does the gas management system play in a 70mm tube furnace? Essential for Precise Atmosphere Control

- What is the function of vacuum-sealed silica tubes in FeTeSe synthesis? Ensure Purity & Precise Stoichiometry

- What is the primary role of a Tube Furnace in g-C3N4 synthesis? Achieve Precise Thermal Polycondensation

- How does a specialized quartz heating furnace ensure accuracy? Mastering Thermoluminescence at High Temperatures