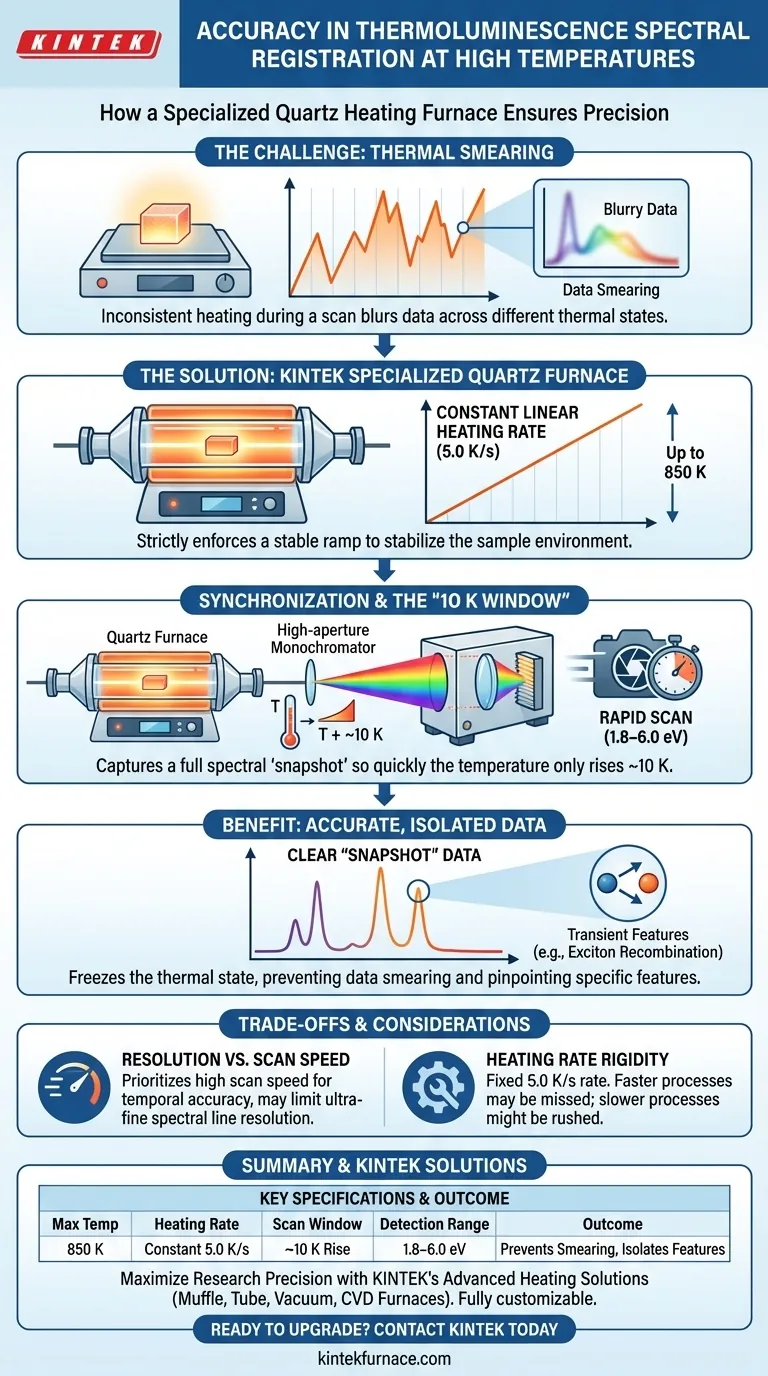

A specialized quartz heating furnace ensures accuracy by strictly enforcing a constant heating rate, even at extreme thermal thresholds. By maintaining a steady ramp of 5.0 K/s up to 850 K, the system stabilizes the sample environment long enough for optical instruments to capture a complete spectral "snapshot."

The core advantage of this system is the minimization of thermal drift during data acquisition. By limiting temperature change to approximately 10 K during a full spectral scan, the system prevents data smearing and accurately isolates specific luminescence features.

The Role of Precision Thermal Control

Maintaining Linearity at 850 K

In thermoluminescence, the integrity of your data depends heavily on the linearity of the heating rate.

Standard heating elements often struggle to maintain consistency as they approach their thermal limits.

A specialized quartz furnace, however, is engineered to sustain a precise 5.0 K/s heating rate all the way to 850 K. This ensures that the energy release from the sample follows a predictable, calculable curve rather than erratic fluctuations.

The Problem of Thermal Smearing

When measuring light emission (luminescence) over a wide energy range, the process takes time.

If the sample's temperature changes significantly during the measurement of a single spectrum, the resulting data becomes a blur of different thermal states.

This system solves that problem by synchronizing the heating rate with the measurement speed.

Synchronization of Heat and Optics

The 10 K Window Principle

To ensure accuracy, the measurement system pairs the furnace with a high-aperture monochromator capable of rapid scanning.

The system captures the full emission spectrum (ranging from 1.8 to 6.0 eV) so quickly that the sample temperature rises by only approximately 10 K.

This narrow temperature window effectively freezes the thermal state of the sample, allowing for a discrete, accurate data point.

Capturing Transient Features

This level of temporal and thermal resolution is critical for observing exciton recombination.

These luminescence features are often associated with specific stages of thermal dissociation.

By strictly controlling the temperature rise, the system allows researchers to pinpoint exactly which features appear at specific dissociation stages without overlap.

Understanding the Trade-offs

Resolution vs. Scan Speed

While this system excels at capturing fast-changing thermal events, there is an inherent compromise between scan speed and spectral resolution.

To scan the full 1.8–6.0 eV range within a 10 K rise, the monochromator must use a high aperture to maximize light throughput.

This prioritization of speed ensures temporal accuracy but may limit the ability to resolve extremely fine spectral lines compared to slower, steady-state measurements.

Heating Rate Rigidity

The defined rate of 5.0 K/s is optimized for general thermoluminescence but acts as a fixed variable.

Processes that occur significantly faster than this heating rate may still be missed.

Conversely, processes that require much slower heating to evolve fully might be rushed by this specific configuration.

Making the Right Choice for Your Goal

To determine if this measurement architecture suits your specific research needs, consider your primary objectives:

- If your primary focus is dynamic thermal events: This system is ideal, as it captures rapid changes in exciton recombination without thermal blurring.

- If your primary focus is ultra-fine spectral resolution: You may require a system that can "step and hold" temperature rather than one that employs a continuous heating ramp.

High-fidelity thermoluminescence data requires a system where the furnace and the spectrometer act as a single, synchronized unit.

Summary Table:

| Feature | Specification/Benefit |

|---|---|

| Max Operating Temp | 850 K |

| Linear Heating Rate | Constant 5.0 K/s |

| Spectral Scan Window | Narrow 10 K temperature rise |

| Energy Detection Range | 1.8 to 6.0 eV |

| Key Outcome | Prevents data smearing and isolates exciton recombination |

Maximize Your Research Precision with KINTEK

High-fidelity thermoluminescence data demands perfect synchronization between your furnace and optical sensors. At KINTEK, we provide the advanced heating solutions required for your most sensitive laboratory applications.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all fully customizable to meet your unique experimental needs. Whether you require rigid heating rates or specialized quartz chambers, our team ensures your equipment delivers repeatable, accurate results.

Ready to upgrade your thermal measurement capabilities? Contact us today to discuss your custom project with our engineering experts!

Visual Guide

References

- K. Shunkeyev, Zarina Serikkaliyeva. The Nature of High-Temperature Peaks of Thermally Stimulated Luminescence in NaCl:Li and KCl:Na Crystals. DOI: 10.3390/cryst15010067

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What heating temperatures can tube furnaces achieve? Unlock Precision Up to 1800°C for Your Lab

- What are the features of more elaborate tube furnaces? Precision Control for Advanced Thermal Processing

- How does a tube furnace ensure uniform temperature distribution? Discover Key Mechanisms for Precise Heating

- What is zonal heating in a horizontal tube furnace? Master Precise Thermal Control for Your Lab

- Can a quartz tube furnace be used for controlled atmosphere experiments? Achieve Precise Heat and Gas Control

- What problems existed with early tube furnace designs? Discover the Flaws That Hindered Performance

- What role does a tube furnace play in evaluating modified birnessite catalysts? Optimize VOC Degradation Activity

- What are the advantages of using a laboratory tube furnace? Achieve Precise Temperature and Atmosphere Control