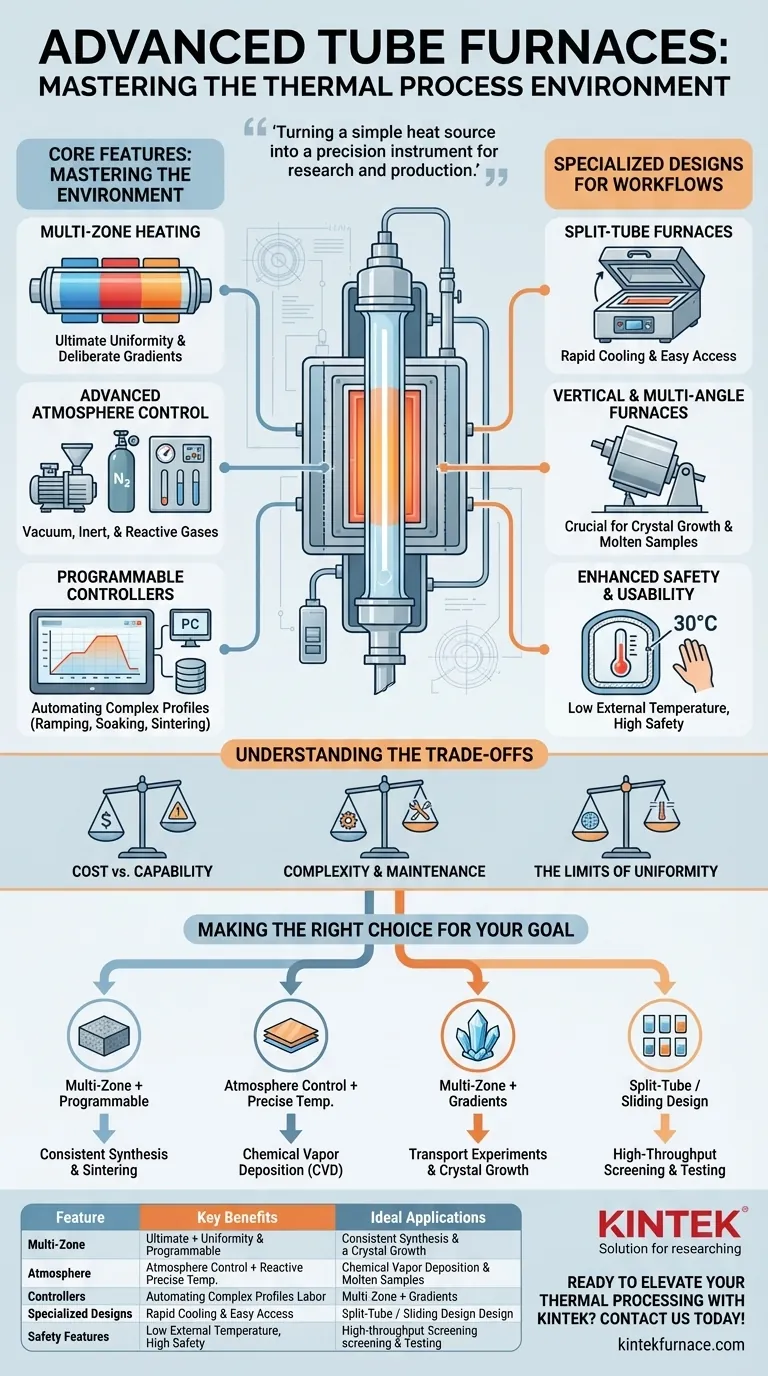

At their core, more elaborate tube furnaces are distinguished by features that provide granular control over the entire thermal processing environment. This includes multi-zone heating for thermal uniformity or gradients, advanced atmosphere control for creating vacuum or inert/reactive gas environments, and sophisticated digital controllers for automating complex temperature profiles.

Moving beyond a basic furnace is not just about achieving higher temperatures. It's about gaining precise, repeatable control over every variable of your process—turning a simple heat source into a precision instrument for research and production.

Beyond Temperature: Mastering the Process Environment

The defining characteristic of an advanced tube furnace is its ability to precisely manage the conditions inside the process tube. This goes far beyond simply setting a target temperature.

Multi-Zone Heating: Achieving Thermal Precision

While a single-zone furnace heats from the center outwards, it creates a temperature gradient toward the ends. More elaborate furnaces use multiple, independently controlled heating zones to counteract this.

This design serves two distinct purposes:

- Ultimate Uniformity: By adjusting the outer zones to be slightly hotter, you can create a significantly larger and more uniform flat thermal zone in the middle. This is critical for processes where every part of the sample must experience the exact same temperature.

- Deliberate Gradients: For applications like chemical vapor transport or crystal growth, you may need a specific, stable temperature slope across the sample. Multi-zone control makes this possible.

Advanced Atmosphere Control: From Vacuum to Reactive Gases

Many modern material processes are highly sensitive to oxygen or require a specific gas to proceed. Advanced furnaces are built to manage this.

Features include sealed end caps and ports for connecting external equipment. This allows you to create a controlled atmosphere, most commonly through:

- Vacuum: Pumping the air out of the tube to levels as low as 10⁻⁵ torr prevents oxidation and removes contaminants.

- Inert Gas: Backfilling the tube with a gas like nitrogen or argon provides a stable, non-reactive environment.

- Reactive Gas: Specialized gas mixing systems can introduce precise mixtures of gases required for processes like Chemical Vapor Deposition (CVD), where gases react on the substrate surface to form a thin film.

Programmable Controllers: Automating Complex Profiles

Manual temperature adjustments are impractical for sophisticated processes. Advanced furnaces use fully programmable digital controllers, often with computer interfaces (like an RS232 port) for automation and data logging.

These controllers allow you to define multi-step process segments, including:

- Ramping: Controlling the rate of temperature increase or decrease.

- Soaking: Holding the temperature at a specific point for a set duration.

- Sintering: A complex profile of ramping and soaking designed to densify materials without melting them.

Specialized Designs for Specific Workflows

The physical construction of the furnace is another area of elaboration, tailored to improve efficiency and safety for specific tasks.

Split-Tube Furnaces

These furnaces are hinged and can be opened in half. This design allows for extremely rapid cooling and provides easy access to the process tube and sample without having to disassemble the end caps, significantly speeding up high-throughput work.

Vertical and Multi-Angle Furnaces

Some furnaces are mounted on stands that allow for horizontal, vertical, or angled operation. Vertical orientation can be crucial for certain crystal growth methods or to prevent a molten sample from touching the sides of the process tube.

Enhanced Safety and Usability

Elaborate models often feature a double-walled or insulated housing. This keeps the external surface temperature remarkably low (e.g., ~30°C) even when the internal temperature is at 800°C or higher, dramatically improving operator safety in a lab environment.

Understanding the Trade-offs

While advanced features offer greater capability, they come with practical considerations that must be balanced against your specific needs.

Cost vs. Capability

Each additional feature—an extra heating zone, a vacuum pump, a gas mixing system—adds significant cost. It is essential to determine if that added control is truly necessary for your intended application or if a simpler model will suffice.

Complexity and Maintenance

An advanced furnace is a complex system. Vacuum systems require dedicated pumps and regular maintenance. Gas delivery systems introduce additional points of failure and require expertise in handling potentially hazardous gases. This increases the operational burden compared to a simple, standalone furnace.

The Limits of Uniformity

Even with multiple heating zones, the "uniform hot zone" has a finite length. It is critical to obtain this specification from the manufacturer and ensure your sample fits entirely within this zone to achieve the desired process consistency.

Making the Right Choice for Your Goal

The best furnace is the one whose features directly serve your primary application. Use your core objective as the guide for your selection.

- If your primary focus is consistent material synthesis or sintering: Prioritize a multi-zone furnace for thermal uniformity and a programmable controller for repeatable process profiles.

- If your primary focus is Chemical Vapor Deposition (CVD): You will need a system with comprehensive atmosphere control, including vacuum and gas mixing capabilities, alongside precise, programmable temperature control.

- If your primary focus is transport experiments or specialized crystal growth: A multi-zone furnace is essential for its ability to create and hold stable, deliberate temperature gradients.

- If your primary focus is high-throughput screening or testing: A split-tube or sliding furnace design will provide the rapid heating, cooling, and sample access needed to maximize efficiency.

Choosing the right features transforms the furnace from a heater into a precision tool engineered for your specific scientific or industrial goal.

Summary Table:

| Feature | Key Benefits | Ideal Applications |

|---|---|---|

| Multi-Zone Heating | Achieves thermal uniformity or gradients | Material synthesis, crystal growth |

| Advanced Atmosphere Control | Enables vacuum, inert, or reactive gas environments | CVD, oxidation-sensitive processes |

| Programmable Controllers | Automates complex temperature profiles | Sintering, multi-step experiments |

| Specialized Designs (e.g., Split-Tube) | Rapid cooling, easy access | High-throughput workflows |

| Enhanced Safety Features | Low external temperatures, improved operator safety | General lab use with high temperatures |

Ready to elevate your thermal processing with a custom tube furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in research or production, we can help you achieve precise control and repeatability. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing