At its core, a laboratory tube furnace offers two primary advantages that set it apart from other heating equipment: exceptionally precise control over the sample's temperature and direct control over the atmospheric environment surrounding it. This combination is essential for processing sensitive materials where both heat and the chemical environment must be managed with high fidelity to ensure repeatable, reliable results.

The decision to use a tube furnace is driven by the need for a highly controlled and isolated thermal environment. Its true value lies not just in its ability to generate heat, but in its capacity to create a specific, uniform, and contained atmosphere for advanced material processing and analysis.

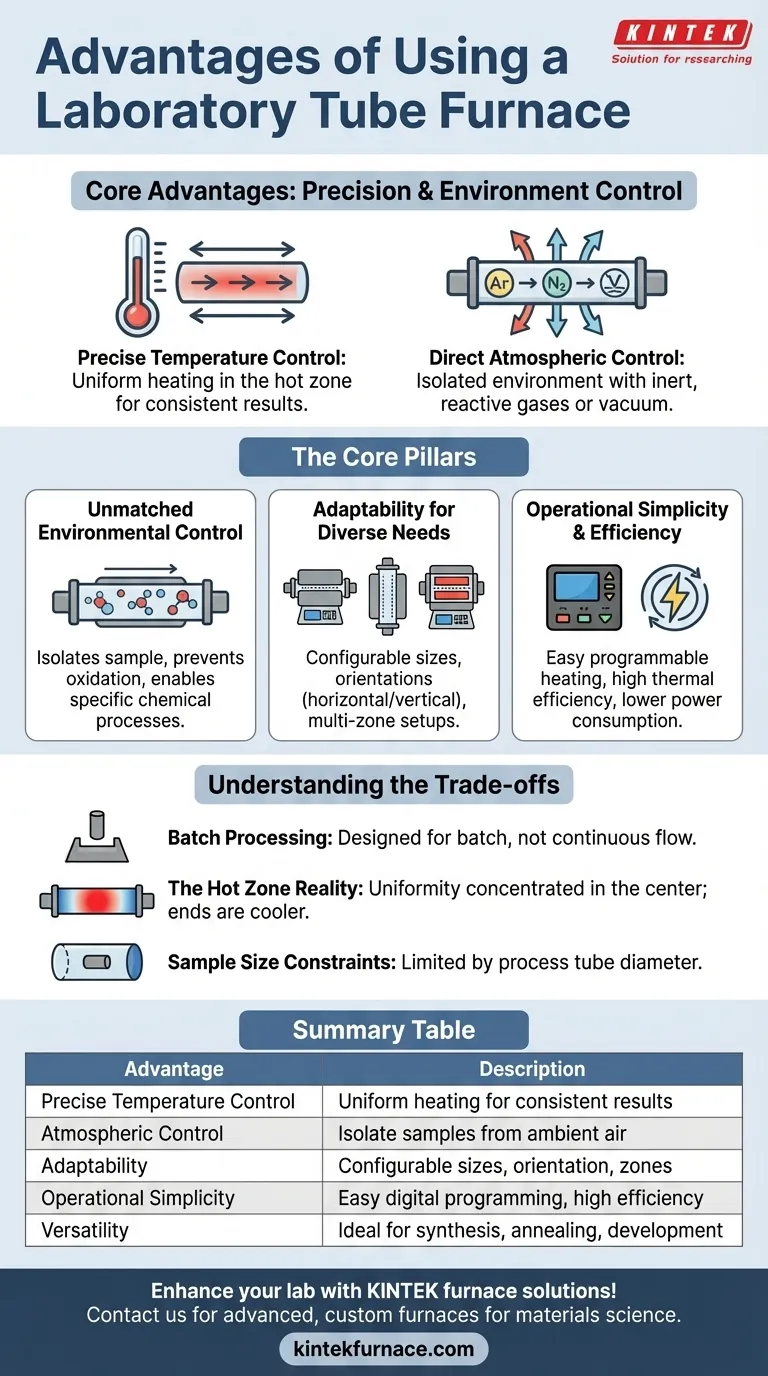

The Core Pillars of a Tube Furnace

A tube furnace is more than just a heating element. Its design philosophy centers on providing a stable, predictable, and adaptable environment, which is why it has become a cornerstone of modern materials science, chemistry, and engineering labs.

Unmatched Environmental Control

The single most important feature of a tube furnace is its ability to isolate a sample from the ambient air. This is achieved by placing the sample within a sealed or semi-sealed process tube, typically made of quartz, alumina, or ceramic.

This design enables precise atmosphere control. Researchers can introduce inert gases like argon or nitrogen to prevent oxidation, reactive gases for specific chemical processes, or create a vacuum to remove atmospheric contaminants entirely.

Furthermore, the cylindrical geometry ensures excellent temperature uniformity along the central "hot zone" of the furnace. This uniformity is critical for ensuring that an entire sample is processed under the exact same thermal conditions, eliminating variables and leading to more consistent data.

Adaptability for Diverse Research Needs

Tube furnaces are not a one-size-fits-all solution; they are highly configurable platforms. They are available in a wide range of sizes, from small benchtop models for individual samples to larger systems for small-batch production.

Key configurations include:

- Split-Tube vs. Solid-Tube: Split-tube designs hinge open, allowing for easy placement and rapid cooling of the process tube, while solid-tube designs offer superior thermal insulation.

- Horizontal vs. Vertical: Vertical furnaces are ideal for applications where minimizing particle contamination is critical, such as in semiconductor research, or for processing samples that might melt or flow.

- Multi-Zone Furnaces: More advanced models have multiple, independently controlled heating zones. This allows for the creation of precise temperature gradients along the length of the tube, a requirement for processes like chemical vapor deposition (CVD).

Operational Simplicity and Efficiency

Despite their advanced capabilities, tube furnaces are generally characterized by a simple structure and ease of operation. Modern digital controllers allow for precise, programmable heating cycles with minimal user intervention.

Their design also contributes to high thermal efficiency. The insulation surrounding the heating elements minimizes heat loss to the laboratory, resulting in lower power consumption compared to less-contained heating methods.

Understanding the Trade-offs

While powerful, a tube furnace has specific design characteristics that create practical limitations. Understanding these is key to using the equipment effectively.

Batch Processing by Design

Most laboratory tube furnaces are designed for batch processing. A sample or set of samples is loaded, processed, and then unloaded. While some industrial variants are built for continuous flow, a standard lab model is not suited for high-throughput, continuous production.

The Reality of the "Hot Zone"

The exceptional temperature uniformity is concentrated in the central hot zone. The ends of the process tube will always be cooler due to heat loss. It is critical to know the precise length of your furnace's uniform hot zone and ensure your sample is positioned entirely within it for consistent results.

Sample Size and Geometry Constraints

The primary constraint of a tube furnace is the diameter of the process tube. This limits the physical size and shape of the samples you can process. For bulkier items or large batches that don't require atmospheric control, a box or muffle furnace may be a more appropriate choice.

Making the Right Choice for Your Application

Selecting a tube furnace depends entirely on the specific demands of your research or process.

- If your primary focus is material synthesis or annealing: The unparalleled control over temperature and atmosphere is the reason to choose a tube furnace.

- If your primary focus is process development: The versatility and configurability allow you to test various conditions and scale up concepts for larger production.

- If your primary focus is general lab heating with atmospheric needs: The furnace's reliability, efficiency, and operational simplicity make it a dependable workhorse.

Ultimately, a tube furnace’s strength lies in providing a predictable and highly controlled environment, making it an indispensable asset for rigorous scientific investigation.

Summary Table:

| Advantage | Description |

|---|---|

| Precise Temperature Control | Enables uniform heating in the hot zone for consistent, reliable results. |

| Atmospheric Control | Allows use of inert, reactive gases or vacuum to isolate samples from ambient air. |

| Adaptability | Configurable in size, orientation (horizontal/vertical), and multi-zone setups for diverse needs. |

| Operational Simplicity | Features digital controllers for easy programming and high thermal efficiency. |

| Versatility | Ideal for material synthesis, annealing, and process development in labs. |

Ready to enhance your laboratory's capabilities with a custom tube furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for materials science, chemistry, and engineering labs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization to meet your unique experimental requirements. Contact us today to discuss how we can help you achieve precise control and efficiency in your research!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis