In a horizontal tube furnace, zonal heating is a design principle that divides the furnace's heating chamber into distinct, independently controlled sections, or "zones." While a standard furnace may have one heating zone to create a uniform temperature, a multi-zone furnace uses several zones to either perfect that uniformity or to intentionally create a specific temperature gradient along the length of the tube.

The core concept of zonal heating is moving from simple, uniform heat to precise thermal profile control. Instead of one "on/off" switch for the entire furnace, you gain multiple controls to fine-tune the temperature landscape your sample experiences.

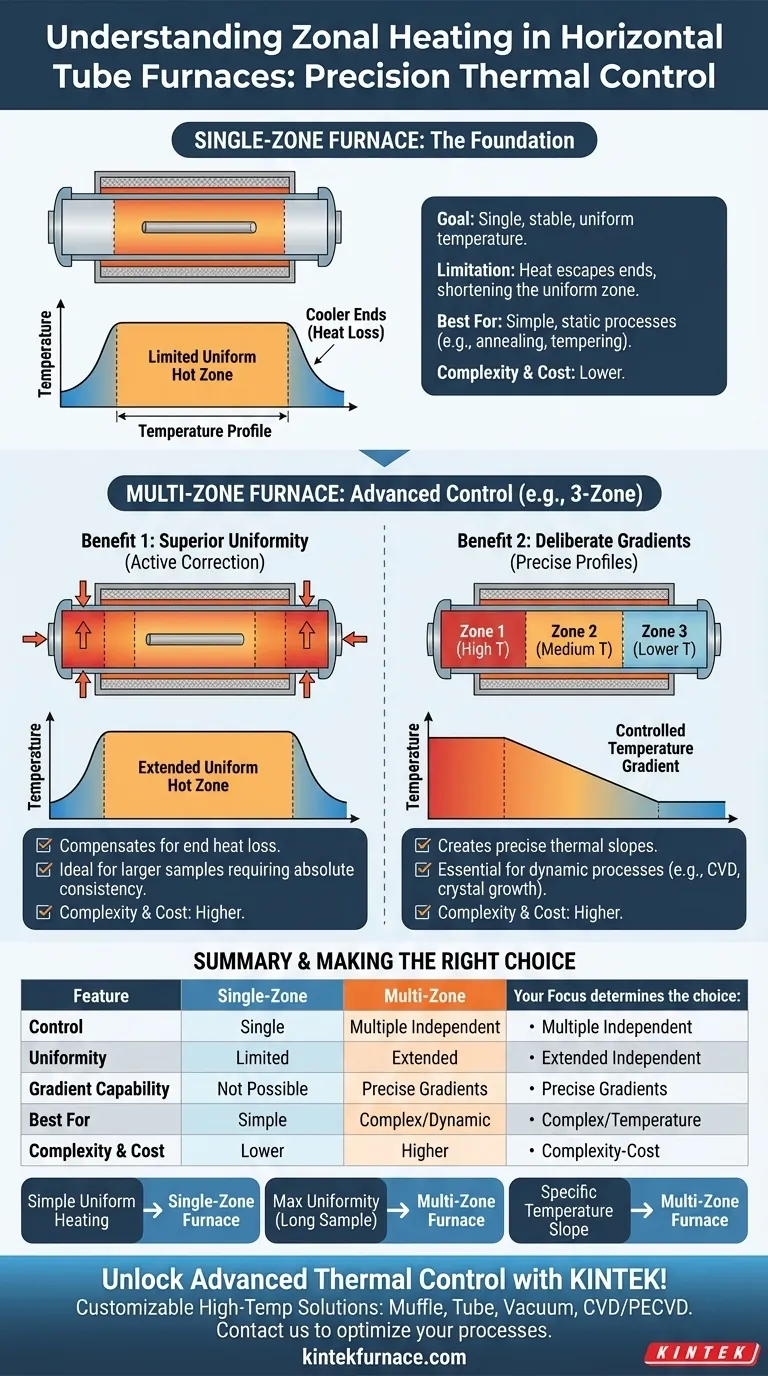

The Foundation: Single-Zone Furnaces

The Goal of Uniformity

A single-zone furnace has one set of heating elements and one controller. Its primary goal is to create a single, stable, and uniform temperature across a central "hot zone."

This design is ideal for many common applications like annealing, tempering, or basic material synthesis, where the entire sample needs to be held at the same temperature for a set duration.

Inherent Physical Limitations

Even in a well-designed single-zone furnace, heat naturally escapes from the ends of the tube. This results in the actual uniform hot zone being shorter than the heated length of the furnace, with the temperature dropping off toward the cooler ends.

The Advancement: Multi-Zone Control

Multi-zone furnaces, most commonly with three zones, address the limitations of single-zone designs by introducing independent control over different sections of the tube. This provides two major advantages.

Achieving Superior Temperature Uniformity

A three-zone furnace has a main central zone and two smaller end zones. By setting the end zones to a slightly higher temperature, you can actively compensate for the heat loss that occurs at the tube openings.

This "active correction" counteracts the natural temperature drop-off, significantly extending the length of the perfectly uniform hot zone within the tube. This is critical for processing larger samples or when absolute temperature consistency is required.

Creating Deliberate Temperature Gradients

The other key application of multi-zone heating is to create a controlled temperature gradient—a gradual slope of temperature from one end of the tube to the other.

Each zone is set to a different temperature, allowing for a precise thermal profile. This is essential for specialized processes like chemical vapor deposition (CVD) or crystal growth, where different stages of a reaction must occur at different temperatures as a sample or gas moves through the furnace.

Understanding the Trade-offs

Simplicity vs. Complexity

A single-zone furnace is straightforward to operate, more affordable, and has fewer points of failure. It is a robust workhorse for applications where its inherent uniformity is sufficient.

Multi-zone furnaces are more complex and expensive. They require more sophisticated controllers and a deeper understanding from the operator to program and stabilize the desired thermal profile, whether it's for enhanced uniformity or a specific gradient.

Application Specificity

The choice is not about which is "better" but which is correct for the task. Using a multi-zone furnace for a simple annealing process can be overkill, adding unnecessary cost and complexity. Conversely, trying to achieve a precise gradient in a single-zone furnace is impossible.

Making the Right Choice for Your Goal

When selecting a furnace, its zonal configuration is a critical decision driven entirely by your process requirements.

- If your primary focus is simple, uniform heating for static processes: A single-zone furnace is the most cost-effective and reliable choice.

- If your primary focus is maximizing temperature uniformity over a long sample length: A three-zone furnace is necessary to actively compensate for heat loss at the ends.

- If your primary focus is creating a specific temperature slope for dynamic processes: A multi-zone furnace is the only way to achieve a controlled thermal gradient.

Ultimately, understanding zonal heating empowers you to select the precise tool needed to control the thermal environment for your specific scientific or industrial process.

Summary Table:

| Feature | Single-Zone Furnace | Multi-Zone Furnace |

|---|---|---|

| Control | Single temperature zone | Multiple independent zones |

| Uniformity | Limited hot zone, heat loss at ends | Extended uniform hot zone with active correction |

| Gradient Capability | Not possible | Creates precise temperature gradients |

| Best For | Simple annealing, tempering | CVD, crystal growth, large samples |

| Complexity & Cost | Lower | Higher |

Unlock advanced thermal control for your laboratory with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnace solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs. Contact us today to discuss how our furnaces can optimize your processes and drive innovation!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients

- What is the difference between a tubular furnace and a muffle furnace? Choose the Right High-Temp Solution

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials