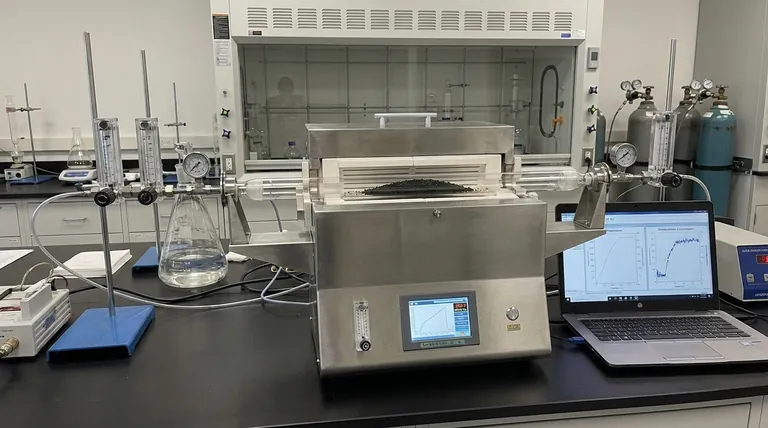

A tube furnace serves as the thermal control center for the fixed-bed reactor system. In the context of evaluating modified birnessite catalysts, it provides the precise, adjustable heating environment necessary to simulate industrial conditions. This allows researchers to systematically measure how effectively the catalyst breaks down dimethylamine gas across a spectrum of temperatures, typically ranging from 50°C to 600°C.

Core Takeaway The tube furnace is not merely a heating source; it is the variable that allows for the construction of a performance profile. By strictly controlling the thermal environment, it enables the identification of the specific "reaction window" where the catalyst achieves maximum efficiency in treating Volatile Organic Compounds (VOCs).

The Mechanics of Performance Evaluation

Establishing the Reaction Environment

To evaluate degradation activity, the modified birnessite catalyst is loaded into a fixed-bed reactor, which is then placed inside the tube furnace.

The furnace acts as the external "engine," driving the temperature of the reactor to specific set points. This ensures that the catalyst is exposed to a uniform thermal field, which is critical for obtaining reproducible data regarding gas conversion.

Simulating Industrial VOC Conditions

Dimethylamine is a Volatile Organic Compound (VOC) that often requires thermal aid to degrade efficiently in industrial settings.

The tube furnace allows researchers to replicate these real-world exhaust conditions in a controlled laboratory setting. By mimicking the heat levels found in industrial treatment facilities, the data gathered becomes predictive of how the catalyst will perform in actual deployment.

Determining the Optimal Operating Window

Systematic Temperature Profiling

The primary utility of the tube furnace in this evaluation is its ability to adjust temperature stepwise.

Researchers do not test at a single temperature; they measure dimethylamine conversion rates at various intervals (e.g., ramping from 100°C to 400°C). The furnace’s precision ensures that each measurement point represents a stable thermal state.

Identifying Catalytic Efficiency

By correlating the furnace temperature with the output gas analysis, researchers can identify the "light-off" temperature—the point where the catalytic reaction becomes self-sustaining or highly efficient.

This process reveals the optimal temperature window for the modified birnessite, guiding recommendations for energy-efficient industrial operation.

Understanding the Trade-offs

External vs. Internal Temperature

While the tube furnace controls the external temperature of the reactor tube, it does not directly measure the temperature inside the catalyst bed.

If the degradation of dimethylamine is highly exothermic (releasing heat), the internal temperature may exceed the furnace setting. Researchers must be aware of this potential discrepancy to avoid overestimating the external heat required for the reaction.

Thermal Stabilization Time

Tube furnaces have significant thermal mass and do not change temperature instantly.

When evaluating activity at different temperature points, sufficient "dwell time" must be allowed at each stage. Rushing the ramp rate can lead to transient data that does not accurately reflect the catalyst's steady-state performance.

Making the Right Choice for Your Goal

Whether you are optimizing a catalyst for a specific factory or exploring general material properties, how you utilize the furnace matters.

- If your primary focus is Industrial Application: Prioritize stability tests at specific temperatures (e.g., 250°C) for long durations to ensure the catalyst does not degrade over time under constant heat.

- If your primary focus is Academic Characterization: Utilize the full 50-600°C range with small temperature increments to map the precise kinetic curve and activation energy of the material.

The precision of your thermal control directly dictates the reliability of your catalytic data.

Summary Table:

| Feature | Role in Catalyst Evaluation |

|---|---|

| Temperature Range | Typically 50°C to 600°C for VOC simulation |

| Thermal Stability | Ensures uniform heating for reproducible gas conversion data |

| Reaction Profiling | Enables identification of "light-off" temperature and kinetic curves |

| Industrial Simulation | Replicates real-world exhaust conditions in a lab setting |

| System Integration | Serves as the thermal center for fixed-bed reactor systems |

Maximize Your Research Precision with KINTEK

High-performance catalyst evaluation requires uncompromising thermal control. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory or industrial high-temperature needs.

Whether you are mapping kinetic curves for birnessite catalysts or scaling VOC treatment solutions, our precision engineering ensures your data is reliable and your results are reproducible. Contact KINTEK today to discuss your custom furnace requirements and see how our advanced heating solutions can empower your next breakthrough.

Visual Guide

References

- Wei Jia, Mengnan Yu. Study on the activity of doped metal-modified water-sodium- manganese ore catalyst to catalyze the degradation of dimethylamine. DOI: 10.21203/rs.3.rs-7291479/v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What core functions does an argon atmosphere tube furnace perform? Optimize Al-PTFE FGM Sintering

- How does a horizontal dual-zone tube furnace facilitate WSe2 CVT growth? Precision Thermal Gradient Control

- What advantages do drop tube furnaces offer? Achieve Precise Control and High Efficiency

- What types of atmospheres can be controlled in an atmosphere tube furnace? Master Precise Gas Environments for Material Processing

- What role does a tube furnace play in tantalum capacitor recycling? Enhancing Metal Recovery Through Pyrolysis

- How does a laboratory tube furnace achieve controlled atmosphere sintering? Master Precision Catalytic Prep

- What are some primary applications of the 70mm tube furnace? Unlock Precision in Materials Research

- What materials are used in tube furnace? Key Components for High-Temp Lab Success