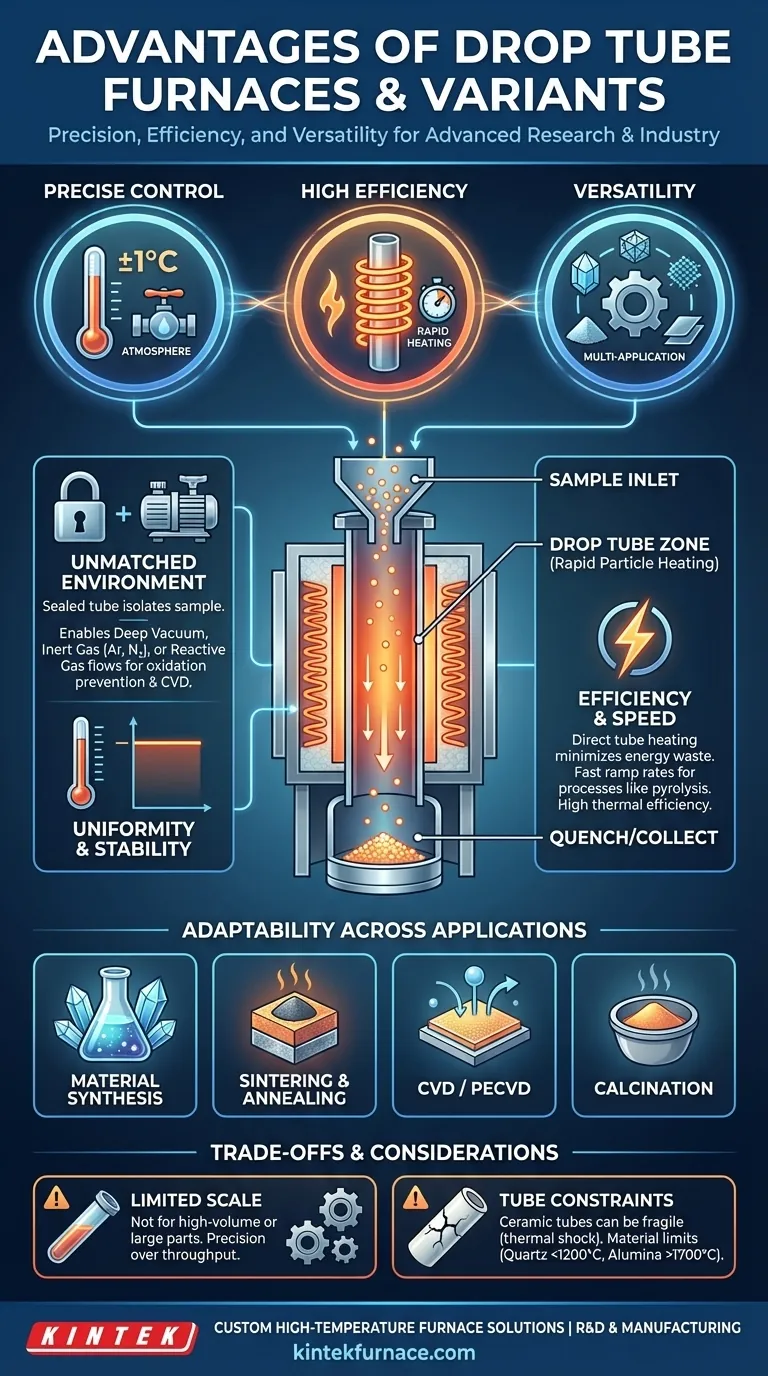

At their core, drop tube furnaces and their variants offer three primary advantages: exceptionally precise control over the processing environment, high thermal efficiency, and the versatility to handle a wide range of advanced materials and applications. These benefits make them indispensable tools for scientific research and specialized industrial processes where consistency and control are paramount.

The fundamental value of a tube furnace is its ability to create a tightly sealed, uniform, high-temperature environment. This allows you to dictate the exact conditions—from temperature to atmospheric composition—that your material experiences, leading to highly repeatable and predictable results.

The Core Advantage: A Perfectly Controlled Environment

The defining feature of a tube furnace is the containment of the sample within a tube. This simple design principle is the source of its most significant advantages.

Unmatched Temperature Precision and Uniformity

A tube furnace is engineered to deliver a highly uniform hot zone. Heating elements surround the tube, ensuring the sample is heated evenly from all sides.

This design allows for exceptionally precise temperature control, often within ±1°C of the setpoint. This level of accuracy is critical for sensitive processes where minor temperature deviations can ruin an experiment or a production batch.

Absolute Atmosphere Control

The sealed tube isolates the internal environment from the outside air. This enables complete control over the atmosphere your sample is processed in.

By connecting a vacuum system and gas inlets, you can operate under a deep vacuum, an inert gas like argon or nitrogen, or a specific reactive gas. This is essential for preventing oxidation and enabling processes like chemical vapor deposition (CVD) or bright annealing.

Efficiency and Versatility in Practice

Beyond environmental control, tube furnaces are valued for their practical efficiency and adaptability in a lab or production setting.

High Thermal Efficiency and Rapid Heating

Because the heating elements are positioned closely around a relatively small volume (the tube), less energy is wasted heating the surrounding space. This results in high thermal efficiency and lower energy consumption.

Certain designs, like induction tube furnaces, offer extremely fast heating speeds. They heat the metallic furnace tube directly, minimizing thermal lag and enabling processes like rapid pyrolysis that depend on a quick temperature ramp.

Adaptability Across Applications

Tube furnaces are not single-purpose tools. Their precise control makes them suitable for a vast array of thermal processes.

Common applications include material synthesis, sintering of ceramics, annealing of metals, calcination, and chemical vapor deposition (CVD), where a precursor gas reacts on a hot substrate to form a solid film.

Flexibility in Tube Materials and Design

The furnace's capabilities can be changed simply by swapping the tube. Quartz tubes are common for processes up to ~1200°C, while alumina tubes are used for higher temperatures, up to 1700°C or more. Metal tubes, such as stainless steel, offer high mechanical strength and excellent sealing.

Furthermore, designs like split tube furnaces, which open vertically or horizontally, allow for much easier placement and removal of samples, especially those with complex external connections. A drop tube furnace is a specialized vertical configuration where particles fall through the hot zone, specifically designed to study phenomena like coal combustion or biomass pyrolysis in seconds.

Understanding the Trade-offs and Limitations

While powerful, tube furnaces are not the right tool for every job. Understanding their limitations is key to using them effectively.

Limited Sample Size and Throughput

The primary trade-off for precision is scale. The diameter of the tube inherently limits the size of the sample that can be processed. They are not designed for high-volume manufacturing or heat-treating very large components.

Tube Material Constraints

The processing tube is often the most fragile and expensive component. Ceramic tubes (alumina, quartz) are brittle and can be susceptible to thermal shock—cracking if heated or cooled too quickly. They also have strict temperature and atmospheric limitations.

Cost and Complexity

While some basic models are affordable, high-temperature, vacuum-capable, or multi-zone tube furnaces represent a significant investment. Their operation requires more technical expertise than a simple box furnace, especially when managing gas flows and vacuum systems.

Making the Right Choice for Your Goal

To select the right furnace, you must match its capabilities to your primary objective.

- If your primary focus is fundamental research or precise process development: The unparalleled environmental control of a tube furnace is essential for achieving repeatable, high-quality results.

- If your primary focus is simulating the rapid heating of falling particles (e.g., combustion): A specialized vertical drop tube furnace is the only tool designed specifically for this purpose.

- If your primary focus is high-volume production or processing large parts: You should consider a box furnace, batch furnace, or conveyor furnace, which sacrifice some precision for much greater capacity.

Ultimately, choosing a tube furnace is a decision to prioritize absolute control over sheer processing volume.

Summary Table:

| Advantage | Description |

|---|---|

| Precise Environment Control | Enables exact temperature (±1°C) and atmosphere settings for repeatable results. |

| High Thermal Efficiency | Reduces energy waste with fast heating, ideal for rapid processes like pyrolysis. |

| Versatility | Supports various materials and applications, from material synthesis to CVD. |

| Flexibility in Design | Allows tube swapping (e.g., quartz, alumina) and easy sample access with split designs. |

Ready to elevate your lab's capabilities with a custom high-temperature furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how our furnaces can enhance your research and industrial processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability