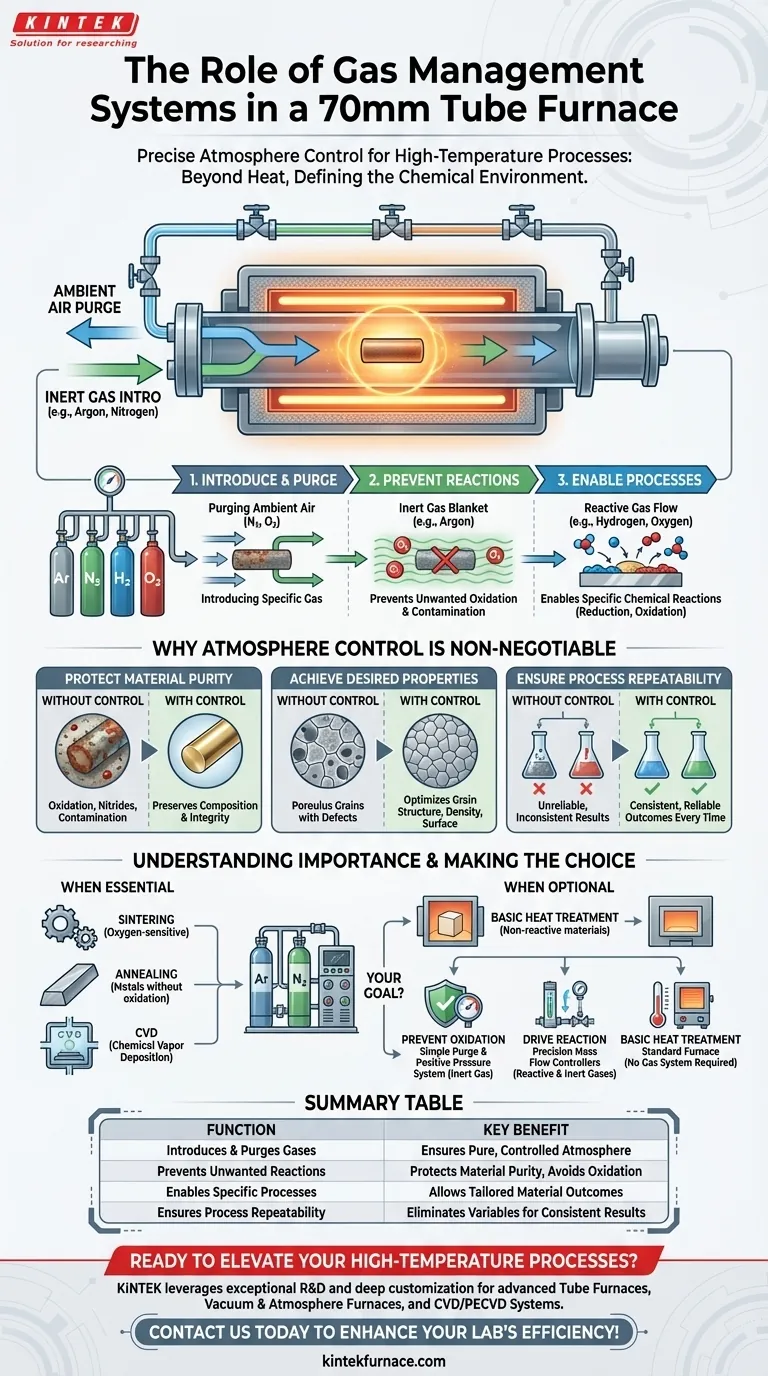

In a 70mm tube furnace, the gas management system's primary role is to create a precisely controlled atmosphere within the heating tube. It does this by introducing, managing, and removing specific gases, allowing you to run high-temperature processes that would be impossible in ambient air, such as preventing oxidation or enabling specific chemical reactions.

A tube furnace provides the heat, but the gas management system provides the chemical environment. For any process sensitive to its surroundings, this system is not an optional accessory; it is the critical component that dictates the success and repeatability of your results.

The Core Function: Creating a Controlled Atmosphere

A gas management system is more than just a tube for flowing gas. It is a system designed for precision control over the chemical environment where your material is being processed at high temperatures.

Introducing and Purging Gases

The system's most basic function is to introduce a specific gas, such as inert argon or reactive hydrogen, into the furnace tube. Equally important is its ability to purge the ambient air (mostly nitrogen and oxygen) before the process begins, ensuring the internal atmosphere is pure.

Preventing Unwanted Reactions

Many materials, especially metals, rapidly oxidize when heated in the presence of air. By filling the tube with an inert gas like argon or nitrogen, the gas management system creates a protective blanket that prevents this unwanted oxidation, preserving the material's purity and integrity.

Enabling Specific Chemical Processes

Conversely, some processes require a reaction. A gas system allows for the controlled introduction of reactive gases. This could be a reducing gas like hydrogen to remove oxides or an oxidizing gas like oxygen to create a specific oxide layer on a material.

Why Atmosphere Control is Non-Negotiable

At the high temperatures achieved in a tube furnace, materials become far more chemically reactive. An uncontrolled atmosphere is a variable that can ruin an entire experiment or production run.

Protecting Material Purity

Without atmospheric control, your sample can become contaminated. Heating in air can introduce oxides and nitrides into your material, fundamentally changing its composition and properties in unintended ways.

Achieving Desired Material Properties

The atmosphere directly influences the final outcome. For processes like annealing, sintering, or crystal growth, the gas environment determines the material's final grain structure, density, and surface characteristics. A controlled atmosphere is essential for achieving the desired result.

Ensuring Process Repeatability

Scientific and manufacturing processes demand consistency. By precisely regulating the gas type and flow rate, you eliminate a major variable. This ensures that a process performed today will yield the same results as one performed next month.

Understanding the System's Importance

Not every high-temperature application requires gas management. The necessity is dictated entirely by the chemical sensitivity of your materials and process goals.

When Gas Control is Essential

A gas management system is indispensable for processes like sintering oxygen-sensitive materials, annealing metals without surface oxidation, or chemical vapor deposition (CVD), where precursor gases must be introduced in a controlled sequence.

When Simpler Setups Suffice

If your goal is simply to heat a material that is non-reactive in air (like certain ceramics) for a basic heat treatment or drying process, a furnace without a gas management system may be sufficient. In these cases, the added complexity and cost are unnecessary.

Making the Right Choice for Your Goal

The level of atmospheric control you need is tied directly to your objective.

- If your primary focus is preventing oxidation: A simple system to purge air and maintain a positive pressure of an inert gas like argon or nitrogen is sufficient.

- If your primary focus is driving a specific chemical reaction: You need a system with precision mass flow controllers to accurately mix and deliver reactive gases.

- If your primary focus is basic heat treatment of non-reactive materials: A gas management system is likely not required, and a standard furnace will meet your needs.

Ultimately, mastering the gas environment within your furnace gives you direct control over the chemical destiny of your material.

Summary Table:

| Function | Key Benefit |

|---|---|

| Introduces and purges gases | Ensures a pure, controlled atmosphere for processes |

| Prevents unwanted reactions | Protects material purity by avoiding oxidation and contamination |

| Enables specific chemical processes | Allows use of reactive gases for tailored material outcomes |

| Ensures process repeatability | Eliminates variables for consistent, reliable results |

Ready to elevate your high-temperature processes with precise atmosphere control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs. Contact us today to discuss how our gas management systems can enhance your lab's efficiency and results!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What are the applications of inert atmosphere furnaces? Essential for Metal Processing, Electronics, and Additive Manufacturing

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment