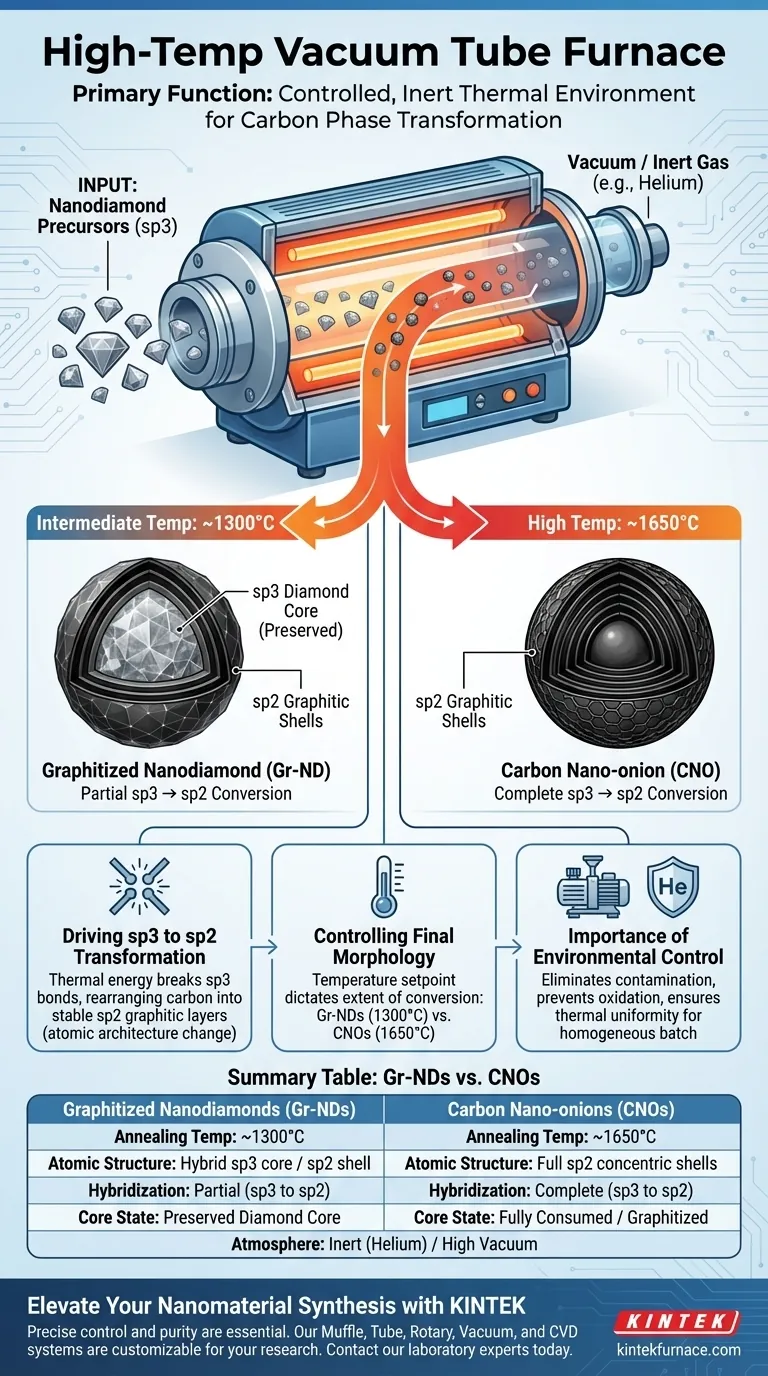

The primary function of a high-temperature vacuum tube furnace in this context is to provide a strictly controlled, inert thermal environment that drives the structural evolution of nanodiamond precursors. By maintaining precise annealing temperatures—typically between 1300°C and 1650°C—under a protective atmosphere like helium, the furnace facilitates the critical phase transformation of carbon atoms.

The furnace serves as the engine for hybridization change, converting carbon atoms from an sp3 (diamond) state to an sp2 (graphite) state. The specific temperature applied determines the extent of this conversion, dictating whether the final material becomes a core-shell graphitized nanodiamond or a fully graphitized carbon nano-onion.

The Mechanism of Structural Evolution

Driving the sp3 to sp2 Transformation

The core purpose of the heat treatment is to supply the energy required to reconfigure the atomic bonding of the carbon. Nanodiamonds begin with an sp3 hybridization structure.

As the furnace heats the precursors, the thermal energy breaks these bonds. The carbon atoms then rearrange into the more stable sp2 hybridized layers characteristic of graphite. This is not merely drying or sintering; it is a fundamental change in the material's atomic architecture.

Controlling the Final Morphology

The furnace does not just heat the material; it acts as a selector for the final product based on the temperature setpoint.

At intermediate high temperatures (e.g., 1300°C), the conversion is partial. This results in graphitized nanodiamonds (Gr-NDs), which feature a preserved diamond core surrounded by graphitic shells.

At higher temperatures (e.g., 1650°C), the conversion is complete. The diamond core is fully consumed, resulting in carbon nano-onions (CNOs), which consist entirely of concentric graphitic shells.

The Importance of Environmental Control

Eliminating Contamination

While the temperature drives the reaction, the vacuum and inert gas features of the furnace ensure the reaction path is correct.

A high-vacuum environment effectively removes adsorbed gases from the powder surface before heating begins. This prevents impurities from reacting with the carbon during the sensitive phase transformation.

Preventing Oxidation

Carbon serves as a fuel in the presence of oxygen. Without the furnace's ability to maintain a helium or vacuum atmosphere, high temperatures would simply cause the nanodiamonds to burn away.

The "inert heat treatment environment" mentioned in the primary reference is non-negotiable. It ensures the carbon atoms rearrange into new structures rather than bonding with oxygen to form CO2.

Ensuring Thermal Uniformity

The tube furnace design offers consistent thermal distribution along the length of the heating zone.

This minimizes temperature gradients, ensuring that all nanodiamond precursors in the batch experience the exact same energy levels. This uniformity is essential for achieving a homogeneous batch of Gr-NDs or CNOs without variation in shell thickness or core retention.

Understanding the Trade-offs

The Risk of Temperature Overshoot

Precision is paramount. If the furnace temperature drifts higher than intended during a Gr-ND process, you risk unintentionally dissolving the diamond core entirely.

This would result in a batch of Carbon Nano-onions rather than the intended core-shell hybrid structure, fundamentally changing the material's electronic and mechanical properties.

Atmosphere Integrity

The quality of the vacuum or inert gas flow is a critical failure point. Even a minor leak in the tube furnace seals can introduce enough oxygen to degrade the surface of the nanomaterials.

In porous carbon networks or high-surface-area powders, this oxidation leads to poor interfacial bonding and reduced electrical conductivity in the final application.

Making the Right Choice for Your Goal

To successfully prepare these carbon nanomaterials, you must program the furnace based on your desired end-state structure:

- If your primary focus is Graphitized Nanodiamonds (Gr-NDs): Program the furnace to anneal at approximately 1300°C to induce surface graphitization while strictly preserving the sp3 diamond core.

- If your primary focus is Carbon Nano-onions (CNOs): Increase the annealing temperature to approximately 1650°C to drive the reaction to completion, fully converting the core into concentric sp2 graphitic shells.

By mastering the temperature profile and atmospheric control of your furnace, you gain total command over the structural identity of your carbon nanomaterials.

Summary Table:

| Feature | Graphitized Nanodiamonds (Gr-NDs) | Carbon Nano-onions (CNOs) |

|---|---|---|

| Annealing Temp | ~1300°C | ~1650°C |

| Atomic Structure | Hybrid sp3 core / sp2 shell | Full sp2 concentric shells |

| Hybridization | Partial (sp3 to sp2) | Complete (sp3 to sp2) |

| Atmosphere | Inert (Helium) / High Vacuum | Inert (Helium) / High Vacuum |

| Core State | Preserved Diamond Core | Fully Consumed / Graphitized |

Elevate Your Nanomaterial Synthesis with KINTEK

Precise temperature control and atmospheric purity are the difference between a perfect core-shell structure and a failed batch. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of carbon phase transformation.

Whether you are producing Graphitized Nanodiamonds or Carbon Nano-onions, our high-temperature furnaces provide the thermal uniformity and vacuum integrity your research deserves.

Ready to optimize your carbon synthesis? Contact our laboratory experts today to find the perfect thermal solution for your unique needs.

Visual Guide

References

- Andrea Mescola, G. Paolicelli. Humidity‐Resistant Ultralow Friction in Diamond‐Like Carbon Coatings Enabled by Graphitic Nanodiamonds. DOI: 10.1002/sstr.202500236

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the primary purpose of using an atmosphere-protected tube furnace? Optimize N/S Co-Doped Carbon Synthesis

- How are horizontal furnaces used in thermal analysis? Precision Heating for Accurate Material Testing

- What types of heating elements can be used in split tube furnaces? Choose SiC or MoSi2 for Optimal Performance

- What is a three zone furnace? The Key to Superior Temperature Uniformity

- What is the function of a rotameter in a tube furnace? Master Gas Flow Precision for Reliable Thermal Analysis

- What is the primary function of a high-temperature tube furnace in Bi-doped CaZnOS synthesis? Achieving Phase Purity

- What environmental benefits do tube furnaces provide? Boost Efficiency and Drive Sustainable Innovation

- How does a dual-temperature zone tube furnace contribute to the carbonization of biomass? Precise Material Engineering