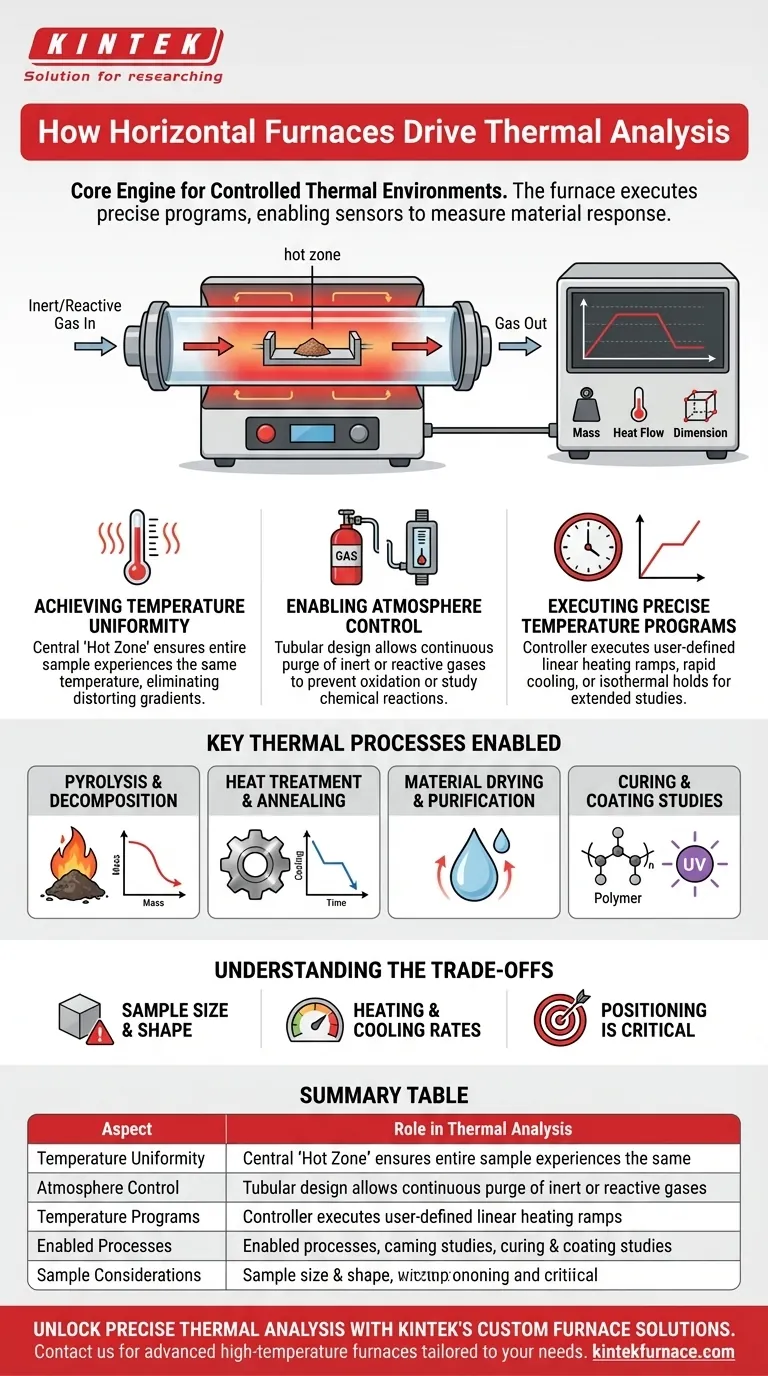

In the context of thermal analysis, a horizontal furnace is the core component responsible for creating a precisely controlled and uniform thermal environment. It serves as the "engine" that heats or cools a material sample according to a specific program, allowing separate sensors to measure changes in the material's properties, such as mass, heat flow, or dimension.

The furnace itself does not perform the analysis. Its critical function is to execute a precise temperature program with high uniformity, creating the necessary conditions for dedicated sensors to accurately measure a material's response to heat.

The Fundamental Role: Creating a Controlled Environment

The primary value of a horizontal furnace in a thermal analysis instrument is its ability to create a highly stable and repeatable environment. This is achieved through its specific design and operational capabilities.

Achieving Temperature Uniformity

A horizontal tube furnace is designed to have a central "hot zone" where the temperature is exceptionally uniform.

Placing the sample in the center of this zone ensures that the entire sample experiences the same temperature, eliminating gradients that could distort measurement results.

Enabling Atmosphere Control

The tube-like geometry is ideal for controlling the gaseous atmosphere surrounding the sample.

Gas inlets and outlets allow for a continuous purge of inert gases (like nitrogen or argon) to prevent unwanted oxidation, or reactive gases to study specific chemical reactions as a function of temperature.

Executing Precise Temperature Programs

The furnace is governed by a controller that executes a user-defined temperature program.

This can include linear heating ramps, rapid cooling, or holding the temperature at a specific point for an extended period (an isothermal step), which is essential for studying processes like material aging.

Key Thermal Processes Enabled in Analysis

The controlled environment provided by the furnace enables the study of numerous material transformations. These processes are the foundation of what thermal analysis seeks to measure.

Pyrolysis and Decomposition

By heating a sample in an inert atmosphere, the furnace facilitates pyrolysis, or thermal decomposition. Instruments like a Thermogravimetric Analyzer (TGA) use a microbalance to measure the resulting mass loss as the material breaks down.

Heat Treatment and Annealing

The furnace can simulate industrial processes like annealing, where a material is heated and then slowly cooled to remove internal stresses and improve its properties. This allows researchers to understand how processing affects the final material.

Material Drying and Purification

A common first step in analysis is to heat the sample to a low temperature (e.g., 105°C) to drive off any residual moisture or solvents. This ensures that the subsequent high-temperature analysis is not skewed by the presence of volatiles.

Curing and Coating Studies

For polymers and resins, the furnace provides the controlled heat needed to study curing reactions. For coatings, it can be used to analyze their thermal stability or the temperature at which binders burn off.

Understanding the Trade-offs

While highly effective, the horizontal furnace design has inherent characteristics that are important to understand.

Sample Size and Shape

The tubular design naturally limits the physical dimensions of the sample. These systems are optimized for small, representative quantities of material, not for bulk processing.

Heating and Cooling Rates

Compared to some specialized micro-furnaces, standard tube furnaces may have limitations on their maximum heating and cooling rates. Extremely rapid thermal cycles may require different instrumentation.

Positioning is Critical

The high-uniformity hot zone exists only in the central portion of the tube. Placing a sample too close to the ends will subject it to a temperature gradient, leading to inaccurate and non-repeatable results.

Making the Right Choice for Your Goal

The furnace's function is best understood in the context of your specific analytical goal.

- If your primary focus is material characterization (TGA, DSC): The furnace's role is to provide a flawlessly repeatable temperature ramp so that changes in mass or heat flow can be reliably correlated to temperature.

- If your primary focus is material synthesis: The furnace provides the stable, high-temperature, and controlled-atmosphere environment required for chemical reactions to proceed to completion.

- If your primary focus is process simulation (e.g., accelerated aging): The furnace's main value is its ability to hold a precise temperature for very long periods to mimic real-world conditions.

Mastering the function of the furnace is the first step toward generating accurate and meaningful data about your materials.

Summary Table:

| Aspect | Role in Thermal Analysis |

|---|---|

| Temperature Uniformity | Ensures entire sample experiences same temperature in the hot zone for accurate measurements |

| Atmosphere Control | Allows use of inert or reactive gases to prevent oxidation or study chemical reactions |

| Temperature Programs | Executes linear ramps, cooling, or isothermal steps for controlled heating and cooling |

| Enabled Processes | Supports pyrolysis, annealing, drying, and curing studies |

| Sample Considerations | Optimized for small samples; positioning in hot zone is critical for repeatability |

Unlock Precise Thermal Analysis with KINTEK's Custom Furnace Solutions

At KINTEK, we specialize in advanced high-temperature furnaces tailored for diverse laboratory needs. Our horizontal tube furnaces, part of a broader product line including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are engineered for exceptional temperature uniformity and atmosphere control. With strong in-house R&D and manufacturing capabilities, we offer deep customization to meet your unique experimental requirements, ensuring accurate and repeatable results in thermal analysis.

Contact us today via our contact form to discuss how our solutions can enhance your material testing and drive your research forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety