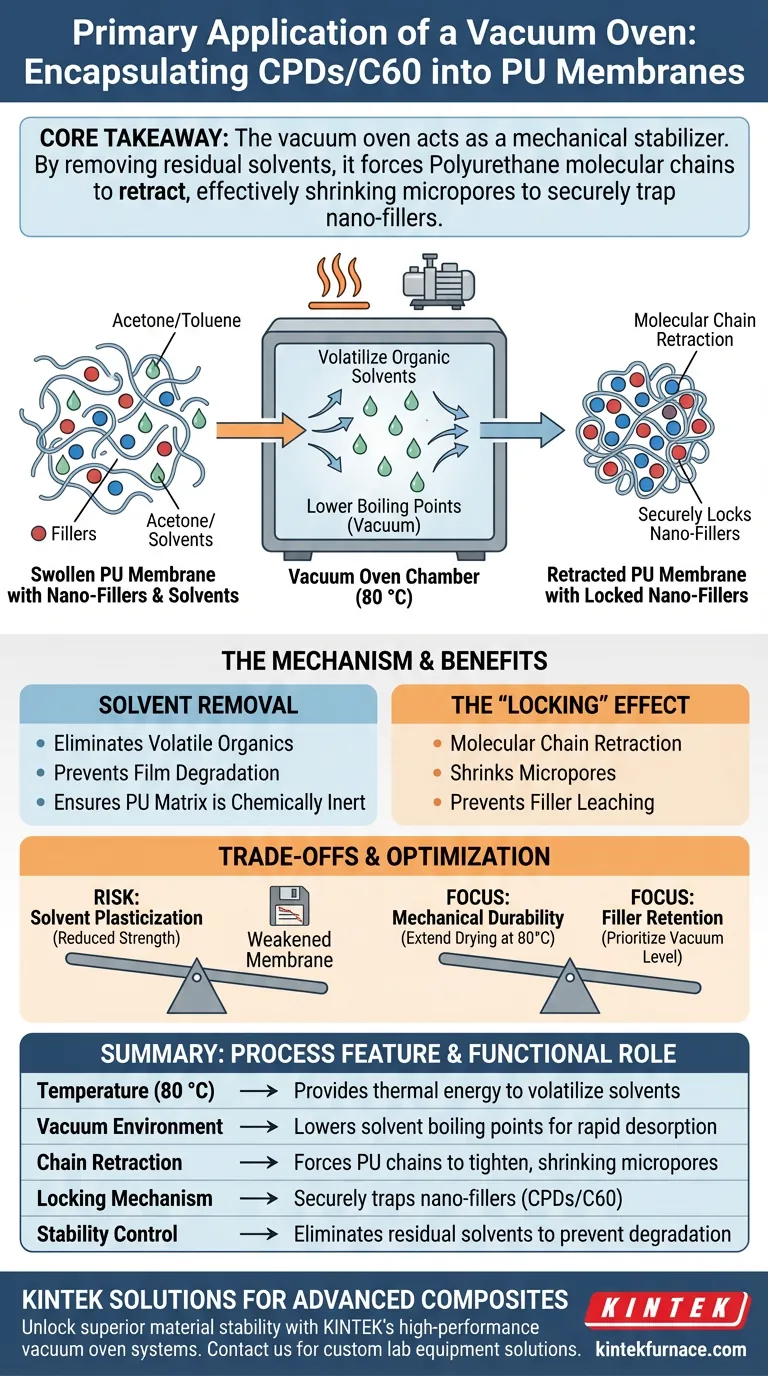

The primary application of a vacuum oven in the encapsulation of Carbon Polymer Dots (CPDs) or Fullerenes (C60) into Polyurethane (PU) membranes is to drive the critical drying phase following material swelling. By subjecting the membranes to 80 °C in a vacuum environment, the oven ensures the complete removal of organic solvents—specifically acetone or toluene—while simultaneously locking the nano-fillers into the polymer structure.

Core Takeaway The vacuum oven does not merely dry the material; it acts as a mechanical stabilizer. By removing residual solvents, it forces the Polyurethane molecular chains to retract, effectively shrinking the polymer micropores to securely trap the CPD or C60 nano-fillers inside.

The Mechanism of Solvent Removal

Eliminating Volatile Organics

The encapsulation process often utilizes strong organic solvents, such as acetone or toluene, to swell the polymer matrix.

A vacuum oven is essential to extract these solvents after they have served their purpose.

Operating at 80 °C, the oven provides sufficient thermal energy to volatilize the solvents, while the vacuum environment lowers their boiling points to ensure rapid and complete desorption.

Preventing Film Degradation

Leaving residual solvents within the membrane is detrimental to the material's longevity.

Solvents trapped in the matrix can act as plasticizers, which softens the film and leads to mechanical degradation over time.

Thorough vacuum drying prevents this by ensuring the PU matrix is chemically inert and structurally sound before use.

The "Locking" Effect

Molecular Chain Retraction

The most sophisticated function of this drying stage is the manipulation of the polymer chains.

As the organic solvents are evacuated from the matrix, the swollen Polyurethane molecular chains begin to retract.

This retraction is a controlled physical response to the removal of the swelling agent, essentially tightening the polymer network.

Securing the Nano-Fillers

This chain retraction is the mechanism responsible for the successful encapsulation of Carbon Polymer Dots and Fullerenes.

As the PU chains retract, they reduce the size of the micropores surrounding the fillers.

This action securely locks the nano-fillers within the polymer micropores, preventing them from leaching out during subsequent applications.

Understanding the Trade-offs

The Risk of Solvent Plasticization

If the drying process is cut short or the vacuum is insufficient, trace amounts of solvent will remain.

This leads to solvent plasticization, where the residual solvent molecules increase the free volume between polymer chains.

While this might make the membrane more flexible initially, it significantly reduces mechanical strength and can cause deformation under stress.

Thermal Sensitivity

While 80 °C is the standard for this specific PU application, temperature control is critical.

Excessive heat can degrade the polymer or the nano-fillers themselves, while insufficient heat fails to trigger the necessary chain retraction.

Precision in the vacuum oven settings is required to balance solvent removal against the thermal stability of the composite material.

Making the Right Choice for Your Goal

To optimize your encapsulation process, consider the specific requirements of your final membrane:

- If your primary focus is Mechanical Durability: Ensure the drying time is extended at 80 °C to remove all traces of acetone or toluene, preventing plasticization-induced weakness.

- If your primary focus is Filler Retention: Prioritize the vacuum level to maximize the rate of solvent evaporation, forcing a rapid and tight retraction of the PU chains around the C60 or CPDs.

The vacuum oven is the gatekeeper between a temporary mixture and a permanently encapsulated, mechanically robust composite material.

Summary Table:

| Process Feature | Functional Role in Encapsulation |

|---|---|

| Temperature (80 °C) | Provides thermal energy to volatilize acetone or toluene solvents. |

| Vacuum Environment | Lowers solvent boiling points for rapid, complete desorption. |

| Chain Retraction | Forces PU molecular chains to tighten, shrinking micropores. |

| Locking Mechanism | Securely traps nano-fillers (CPDs/C60) to prevent leaching. |

| Stability Control | Eliminates residual solvents to prevent material degradation. |

Precision Heat Treatment for Advanced Composites

Unlock superior material stability with KINTEK’s high-performance vacuum oven systems. Whether you are encapsulating nano-fillers or developing complex polymer membranes, our equipment provides the precise thermal control and vacuum levels required for critical molecular chain retraction and solvent removal.

Backed by expert R&D and manufacturing, KINTEK offers a wide range of lab equipment including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique research needs. Ensure the mechanical durability and structural integrity of your composites today.

Contact KINTEK for a Custom Solution

Visual Guide

References

- Zoran Marković, Biljana M. Todorović Marković. Antibacterial and Antibiofouling Activities of Carbon Polymerized Dots/Polyurethane and C60/Polyurethane Composite Films. DOI: 10.3390/jfb15030073

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Heat Treat Sintering and Brazing Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What factors influence the price of vacuum furnaces? Key Drivers from Size to Automation

- Why Use a Vacuum Drying Oven for Fire-Retardant Coatings? Ensure 100% Data Accuracy

- What process conditions does a vacuum sintering furnace provide for WC-Fe-Ni-Co? Master Liquid-Phase Densification

- What types of heating elements are used in vacuum sintering furnaces? Choose the Right One for High-Temp Success

- How does the multi-chamber design solve the heating-cooling conflict? Boost Efficiency and Throughput

- What are the applications of sintering furnaces? Unlock High-Performance Material Solutions

- What is the primary purpose of using a vacuum drying oven for rGO/tMO composites? Ensure Purity and Structural Integrity

- What are the main applications of graphite in vacuum furnaces? Unlock High-Temperature Precision and Efficiency