The primary necessity of a vacuum drying oven in processing fire-retardant coatings is to ensure the absolute accuracy of experimental data by thoroughly dehydrating the substrate and cured samples. By maintaining negative pressure and stable temperatures, the oven removes deep-seated moisture that would otherwise evaporate during testing, interfering with heat release measurements and skewing the results of critical cone calorimetry experiments.

By lowering the boiling point of water and solvents, vacuum drying ensures complete moisture removal without thermal damage, guaranteeing that subsequent fire-testing data reflects the true chemical performance of the coating rather than the physics of evaporating water.

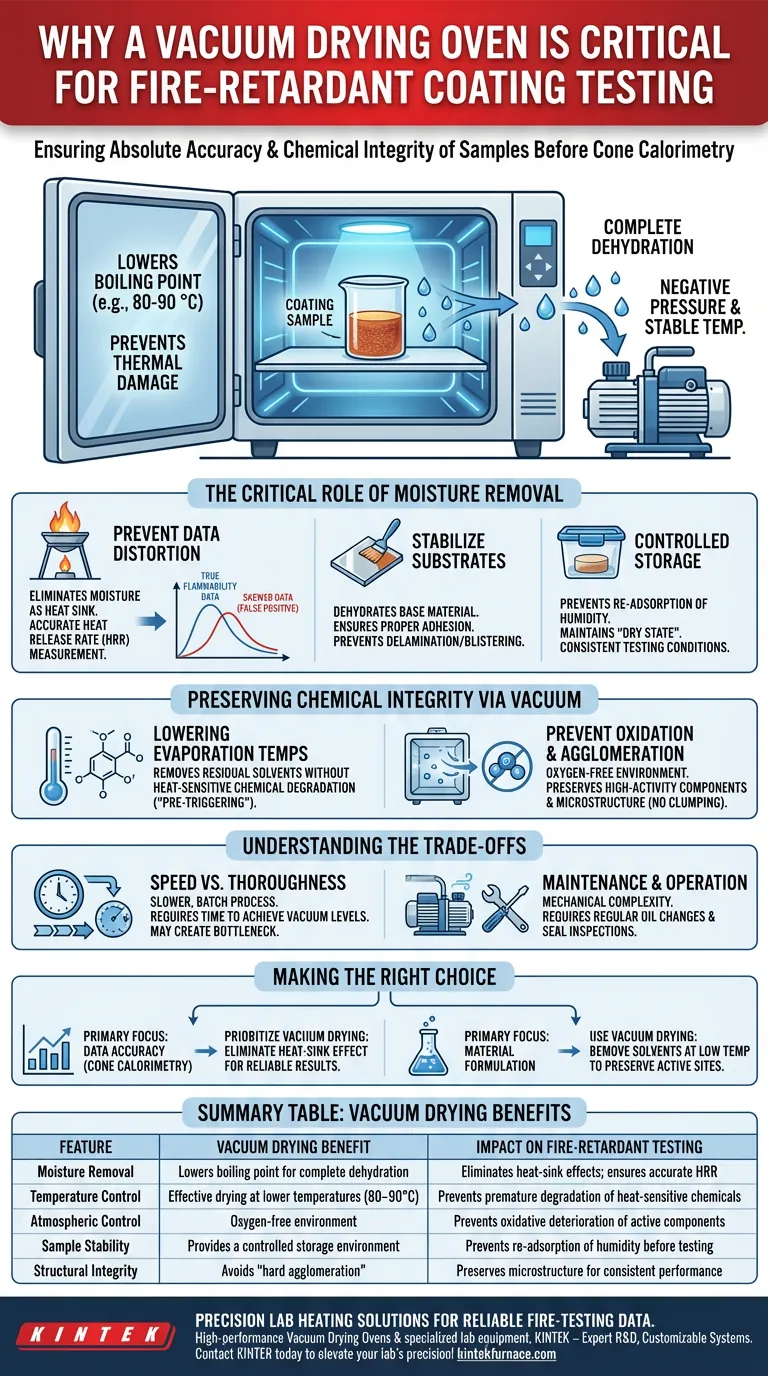

The Critical Role of Moisture Removal

Preventing Data Distortion

The presence of moisture is the enemy of accurate fire testing. In experiments like cone calorimetry, the primary metric is heat release.

Water trapped within a substrate or coating acts as a heat sink. When the sample is exposed to fire, this water evaporates, absorbing energy and artificially lowering the measured heat release rate. A vacuum oven eliminates this variable, ensuring the data captures the true flammability of the material, not its water content.

Stabilizing Substrates Prior to Coating

The vacuum drying oven is not only used on the finished product; it is essential for the preparation of substrates.

Before a fire-retardant coating is even applied, the base material must be dehydrated. This ensures that the coating adheres properly and that no moisture is trapped at the interface, which could cause delamination or blistering during the curing process.

Controlled Storage Environment

Once the coating has cured, the sample must remain stable until the moment it is tested.

The vacuum drying oven provides a stable environment for sample storage. It prevents the re-adsorption of atmospheric humidity, maintaining the sample in a "dry state" so that the testing conditions remain consistent regardless of the ambient humidity in the lab.

Preserving Chemical Integrity via Vacuum

Lowering Evaporation Temperatures

Vacuum environments significantly reduce the boiling point of liquids. This allows for the removal of residual solvents and moisture at much lower temperatures (e.g., 80–90 °C) compared to standard atmospheric ovens.

This is critical for fire-retardant chemicals that might be sensitive to heat. Low-temperature drying prevents the premature degradation or "pre-triggering" of the fire-retardant mechanisms before the actual test begins.

Preventing Oxidation and Agglomeration

While primarily used for moisture removal in this context, the vacuum principle offers secondary benefits observed in advanced material processing.

By removing air, the oven creates an oxygen-free environment. This prevents oxidative deterioration of high-activity components within the coating formulation. Furthermore, vacuum drying helps preserve the coating's micro-structure by avoiding "hard agglomeration"—the clumping of particles that often occurs during high-temperature cracking in standard ovens.

Understanding the Trade-offs

Process Speed vs. Thoroughness

Vacuum drying is generally a slower, batch-based process compared to continuous convection drying.

Because the system relies on pressure reduction to drive evaporation, it requires time to achieve the necessary vacuum levels. This may create a bottleneck in high-throughput testing environments, requiring careful scheduling of sample preparation.

Maintenance and Operation

Vacuum ovens introduce mechanical complexity that standard ovens do not possess.

The system requires a vacuum pump, which demands regular oil changes (if oil-based) and seal inspections. A compromise in the vacuum seal renders the process ineffective, potentially ruining a batch of samples by failing to remove moisture adequately.

Making the Right Choice for Your Project

To maximize the reliability of your fire-retardant testing, align your drying strategy with your specific analytical goals:

- If your primary focus is data accuracy (Cone Calorimetry): Prioritize vacuum drying to remove all adsorbed moisture, as this eliminates the heat-sink effect that causes false-positive safety ratings.

- If your primary focus is material formulation: Use vacuum drying to remove solvents at low temperatures, preserving the active sites and porous structure of your chemical additives without thermal degradation.

Ultimately, the vacuum drying oven serves as a baseline calibration tool, ensuring that your test results measure the chemistry of the coating rather than the humidity of the laboratory.

Summary Table:

| Feature | Vacuum Drying Benefit | Impact on Fire-Retardant Testing |

|---|---|---|

| Moisture Removal | Lowers boiling point for complete dehydration | Eliminates heat-sink effects; ensures accurate heat release rate |

| Temperature Control | Effective drying at lower temperatures (80–90°C) | Prevents premature degradation of heat-sensitive fire-retardant chemicals |

| Atmospheric Control | Oxygen-free environment | Prevents oxidative deterioration of active coating components |

| Sample Stability | Provides a controlled storage environment | Prevents re-adsorption of humidity before cone calorimetry testing |

| Structural Integrity | Avoids "hard agglomeration" | Preserves the coating's microstructure for consistent chemical performance |

Precision Lab Heating Solutions for Reliable Fire-Testing Data

Don't let moisture compromise your experimental integrity. KINTEK provides high-performance Vacuum Drying Ovens and specialized lab equipment designed to ensure your fire-retardant coatings meet the highest standards of accuracy. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique research needs.

Ready to elevate your lab's precision? Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- James Covello, Gary E. Wnek. Tannic acid's role as both char former and blowing agent in epoxy‐based intumescent fire retardants. DOI: 10.1002/pls2.10118

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What characterization and testing facilities support vacuum brazing? Ensure Joint Integrity for Critical Applications

- What are the advantages of conducting heat treatment in a vacuum environment? Achieve Superior Material Control and Quality

- What is a vacuum furnace? Precision Heating for Purity and Performance

- How does the sintering process work? Master the Art of Powder-to-Solid Transformation

- What role does a vacuum oven play in electrode prep? Optimize Lithium-Ion Battery Performance and Adhesion

- Why is a high-vacuum degassing system essential for powder samples? Ensure Precise Water Adsorption Data

- How does a high-temperature vacuum furnace convert PDA into nitrogen-doped carbon shells? Master Carbonization Control

- What advantages does a laboratory vacuum oven offer over a conventional oven for Pb SA/OSC catalyst drying?