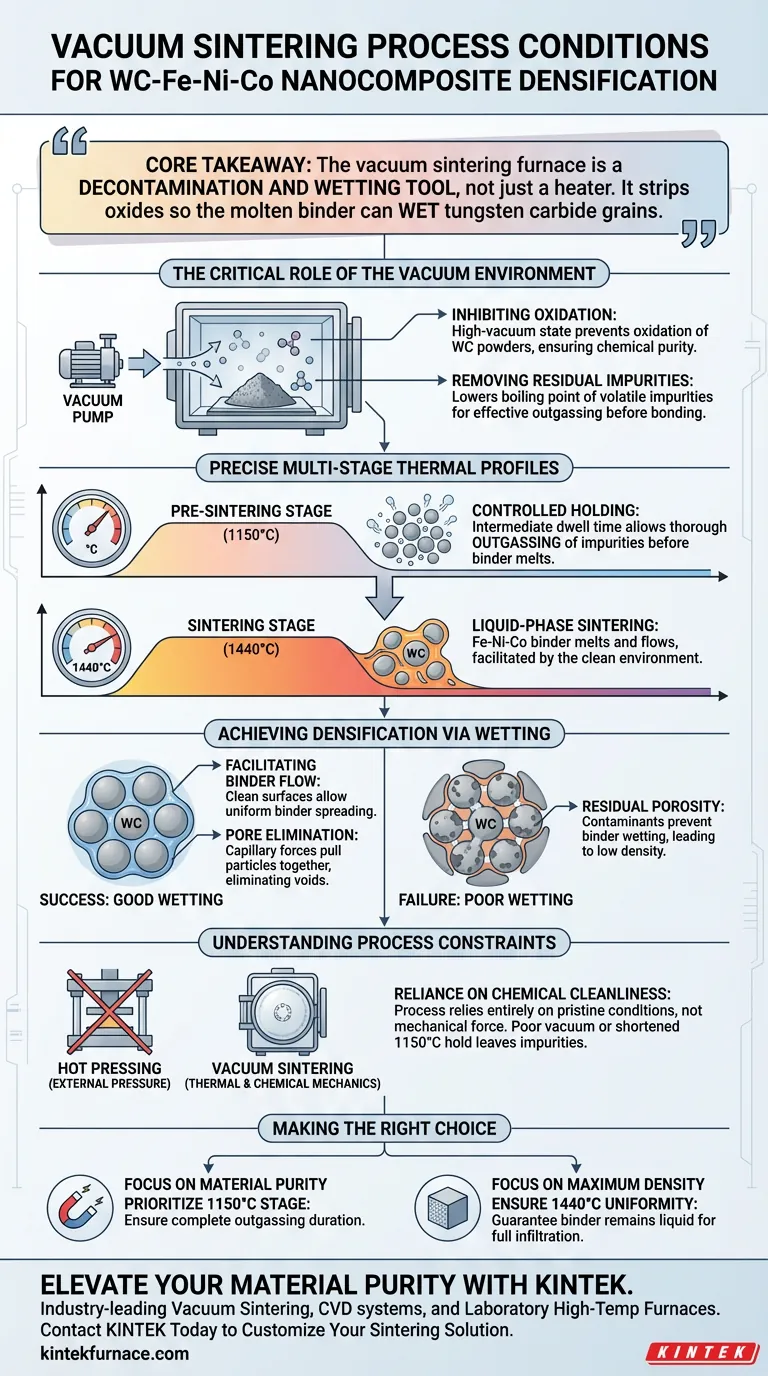

To achieve densification in WC-Fe-Ni-Co nanocomposites, a vacuum sintering furnace provides a high-vacuum environment coupled with a precise, multi-stage thermal profile that typically includes holding stages at 1150°C and 1440°C. This process is designed to inhibit oxidation and remove residual impurities, creating the necessary conditions for liquid-phase sintering.

Core Takeaway The vacuum sintering furnace is not merely a heater; it is a decontamination and wetting tool. Its primary function is to strip oxides and impurities from powder surfaces so that the molten Fe-Ni-Co binder can fully "wet" the tungsten carbide grains, driving the material toward theoretical density without external pressure.

The Critical Role of the Vacuum Environment

Inhibiting Oxidation

The presence of oxygen is detrimental to tungsten carbide (WC) composites. A vacuum sintering furnace operates in a high-vacuum state to prevent the oxidation of the carbide powders during the heating process. This ensures that the chemical composition of the composite remains pure and stable.

Removing Residual Impurities

Before the material reaches its peak sintering temperature, it must be cleaned. The vacuum environment lowers the boiling point of volatile impurities, facilitating their removal. This extraction of contaminants is essential for preparing the grain surfaces for bonding.

Precise Multi-Stage Thermal Profiles

The Pre-Sintering Stage (1150°C)

The furnace does not ramp directly to the maximum temperature. It utilizes a controlled holding stage, specifically noted at 1150°C. This intermediate dwell time allows for the thorough outgassing of impurities before the binder phase melts.

The Sintering Stage (1440°C)

Following the cleaning stage, the temperature is raised to 1440°C. This is the critical zone for liquid-phase sintering. At this temperature, the Fe-Ni-Co binder melts and flows, facilitated by the clean environment established in the previous stages.

Achieving Densification via Wetting

Facilitating Binder Flow

The ultimate goal of these process conditions is "wetting." Because the vacuum has removed oxides and impurities, the liquefied Fe-Ni-Co binder can spread evenly across the surface of the Tungsten Carbide (WC) grains.

Pore Elimination

As the binder wets the WC grains, capillary forces pull the particles together. This action eliminates the voids and pores between the powder particles. The result is a dense, high-hardness alloy that relies on chemical wetting rather than mechanical force.

Understanding the Process Constraints

Reliance on Chemical Cleanliness

Unlike hot pressing, which forces densification through external mechanical pressure (often 30 MPa or more), vacuum sintering relies entirely on thermal and chemical mechanics. If the vacuum quality is poor, or the 1150°C hold is shortened, impurities remain on the grains.

The Consequence of Poor Wetting

If the surfaces are not clean, the binder cannot wet the carbide grains effectively. This leads to residual porosity and a failure to reach full density. The process is unforgiving regarding contamination; the environment must be pristine for the liquid phase to function correctly.

Making the Right Choice for Your Goal

To maximize the performance of WC-Fe-Ni-Co nanocomposites, you must tailor the furnace parameters to the material's specific behavior.

- If your primary focus is Material Purity: Prioritize the duration and vacuum quality at the 1150°C holding stage to ensure complete outgassing of impurities before the liquid phase forms.

- If your primary focus is Maximum Density: Ensure precise temperature uniformity at the 1440°C sintering stage to guarantee the Fe-Ni-Co binder remains liquid long enough to fully infiltrate and wet the WC grain structure.

Success in vacuum sintering depends on respecting the distinct function of each heating stage to turn a loose powder into a solid, high-performance alloy.

Summary Table:

| Process Condition | Temperature | Key Objective |

|---|---|---|

| High Vacuum Environment | N/A | Inhibits oxidation & facilitates impurity outgassing |

| Pre-Sintering Hold | 1150°C | Complete cleaning of powder surfaces & grain wetting preparation |

| Liquid-Phase Sintering | 1440°C | Melting Fe-Ni-Co binder to eliminate pores via capillary force |

| Densification Mechanism | Peak Temp | Chemical wetting & pore elimination without external pressure |

Elevate Your Material Purity with KINTEK

Achieving theoretical density in nanocomposites requires more than just heat—it requires precision vacuum control. KINTEK provides industry-leading Vacuum Sintering, CVD systems, and Laboratory High-Temp Furnaces designed to maintain the pristine environments necessary for liquid-phase sintering.

Backed by expert R&D and advanced manufacturing, our systems are fully customizable to meet your unique thermal profiles and vacuum requirements. Whether you are scaling up WC-Fe-Ni-Co production or researching new alloy compositions, our engineering team is ready to help you optimize your results.

Contact KINTEK Today to Customize Your Sintering Solution

Visual Guide

References

- Maksim Krinitcyn, М. И. Лернер. Structure and Properties of WC-Fe-Ni-Co Nanopowder Composites for Use in Additive Manufacturing Technologies. DOI: 10.3390/met14020167

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why are vacuum furnaces essential for titanium alloy? Protect Your Components from Embrittlement

- What is the significance of using a vacuum annealing furnace for zirconium sponge? Ensure Purity and Process Stability

- What are the main types of vacuum furnaces classified by use? Find the Perfect Fit for Your Thermal Process

- What is the core function of a vacuum distillation furnace in recycling hazardous magnesium waste? Achieve High-Purity Metal Recovery

- How does optimizing the graphite base material improve the quality of cemented carbide sintering? Master Thermal Uniformity

- In which industries are vacuum sintering furnaces commonly used? Essential for High-Performance Materials

- How does heating in a vacuum heat treatment furnace affect the workpiece compared to conventional heating? Discover the Benefits for Your Lab

- What role does a vacuum furnace play in the pre-treatment of UCF for magnesium matrix composites? Improve Bond Quality