In essence, a vacuum distillation furnace purifies hazardous magnesium waste by separating the valuable magnesium from contaminants through selective vaporization. It achieves this by creating a precisely controlled high-temperature, low-pressure environment. Under these conditions, the magnesium turns into a vapor at a much lower temperature than its normal boiling point, leaving behind impurities like aluminum, iron, and oxides, which are then collected separately.

The core challenge in recycling magnesium waste is separating it cleanly from other elements. A vacuum distillation furnace solves this by fundamentally changing the rules of physics, using a vacuum to lower magnesium's boiling point and enable it to selectively "boil off" as a pure vapor, leaving contaminants behind.

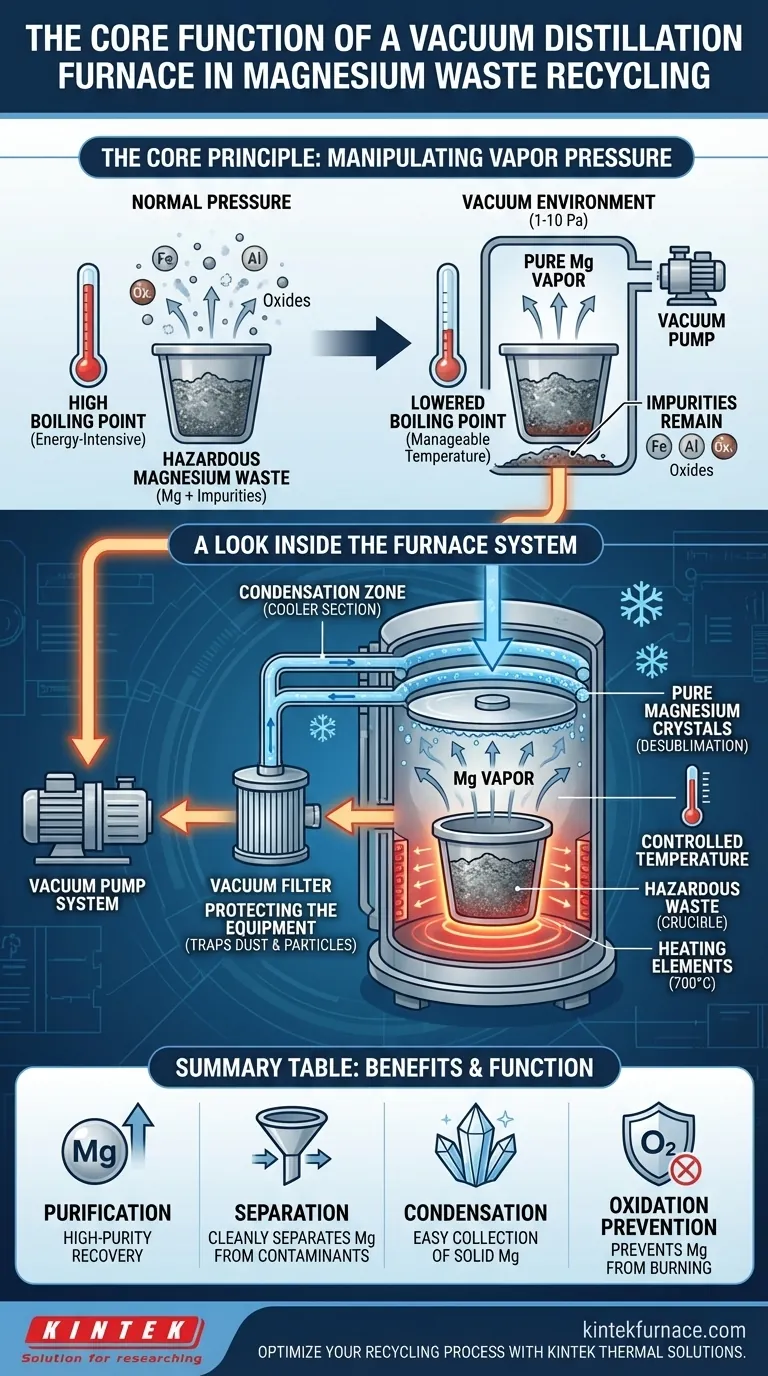

The Core Principle: Manipulating Vapor Pressure

To understand how this furnace works, you must first understand the relationship between pressure and a material's boiling point. The furnace exploits this physical principle to achieve highly effective purification.

Why a Vacuum is Essential

At normal atmospheric pressure, magnesium has a very high boiling point. Heating waste to this temperature would be energy-intensive and could vaporize other unwanted elements.

By creating a vacuum, the furnace dramatically lowers the external pressure. This allows magnesium to vaporize (a process called sublimation if going from solid to gas) at a significantly lower and more manageable temperature.

The Role of Temperature Control

The system's heating element raises the temperature of the hazardous waste to a precise point—typically around 700°C.

This temperature is carefully chosen to be above the new, lower boiling point of magnesium but below the boiling points of common impurities like aluminum, silicon, iron, and various oxides.

How Separation Is Achieved

This combination of low pressure and controlled temperature creates a stark difference in behavior between the materials.

The magnesium, with its high vapor pressure under these conditions, selectively turns into a gas. The impurities, having much lower vapor pressures, remain behind as a solid or liquid residue in the crucible.

A Look Inside the Furnace System

A vacuum distillation furnace is not a single component but an integrated system where each part plays a critical role in the separation process.

The Heating and Containment System

This is the primary chamber where the waste material, held in a crucible, is heated. An external resistance heating system provides the thermal energy required for vaporization.

The Vacuum System

A powerful vacuum pump set is used to evacuate the furnace chamber, reducing the internal pressure to as low as 1-10 Pa. This low-pressure environment is the key enabler of the entire purification process.

The Condensation Zone

As the pure magnesium vapor rises away from the hot waste material, it travels to a cooler section within the furnace. This area, often a water-cooled disc or surface, provides a cold spot for the vapor to condense.

The gaseous magnesium turns directly back into a high-purity solid crystal, a process known as desublimation. This purified crystalline magnesium can then be easily collected.

Understanding the Trade-offs and Challenges

While highly effective, operating this technology requires managing specific technical challenges to ensure safety, efficiency, and equipment longevity.

Preventing Oxidation

Magnesium is highly reactive and will readily oxidize (burn) at high temperatures if exposed to air. The vacuum system is crucial not only for lowering the boiling point but also for removing reactive gases like oxygen, protecting the magnesium from being lost to oxidation.

Protecting the Equipment

The gas flow created during the vacuum process can carry fine dust and magnesium particles from the waste. If these particles enter the vacuum pumps, they can cause significant wear and catastrophic failure.

A vacuum filter is always installed between the furnace and the pumps. This device is essential for trapping solid particulates and ensuring the long-term reliability and stability of the vacuum system.

Making the Right Choice for Your Goal

Applying this technology effectively means understanding how to prioritize different operational parameters based on your desired outcome.

- If your primary focus is maximizing purity: The precise control of both the vacuum level and the furnace temperature are the most critical factors to manage.

- If your primary focus is process efficiency: The rate of heating and the design and cooling efficiency of the condensation zone are the key variables for optimizing throughput.

- If your primary focus is system longevity: Rigorous maintenance of the vacuum pumps and ensuring the integrity of the filter system are absolutely non-negotiable.

Ultimately, the vacuum distillation furnace transforms a complex metallurgical separation problem into a manageable process governed by the fundamental principles of physics.

Summary Table:

| Key Function | How It Works | Benefit |

|---|---|---|

| Purification | Creates a vacuum to lower magnesium's boiling point, allowing it to vaporize separately from impurities. | Achieves high-purity magnesium recovery. |

| Separation | Uses precise temperature control to vaporize magnesium while leaving contaminants like aluminum and oxides behind. | Cleanly separates valuable metal from hazardous waste. |

| Condensation | Cools the magnesium vapor in a dedicated zone, turning it back into pure solid crystals. | Enables easy collection of purified magnesium. |

| Oxidation Prevention | Maintains a vacuum environment to remove oxygen, preventing magnesium from burning. | Ensures safe and efficient operation. |

Ready to Optimize Your Hazardous Metal Recycling Process?

A vacuum distillation furnace is the key to efficiently and safely recovering high-purity magnesium from complex waste streams. KINTEK specializes in advanced thermal solutions for challenging industrial applications.

Our custom-designed vacuum furnaces offer:

- Precision Engineering: Expert R&D ensures optimal temperature and vacuum control for maximum purity and yield.

- Robust Construction: Built to handle reactive materials and ensure long-term system reliability.

- Tailored Solutions: We customize our Muffle, Tube, Rotary, Vacuum, and CVD systems to meet your specific recycling needs and throughput goals.

Let our experts help you transform your hazardous waste into a valuable resource.

Contact KINTEL today to discuss your project and discover the right furnace solution for your lab or facility.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency