At their core, rotary tube furnaces offer significant advantages in process uniformity, thermal efficiency, and operational control. By continuously rotating the material being processed, they ensure every particle is heated evenly, leading to superior consistency and higher throughput compared to static furnace designs.

The fundamental advantage of a rotary tube furnace is not just the heat, but the dynamic material agitation. This constant tumbling motion is the key to solving the persistent challenges of temperature uniformity and process efficiency common in the thermal treatment of powders, granules, and other free-flowing solids.

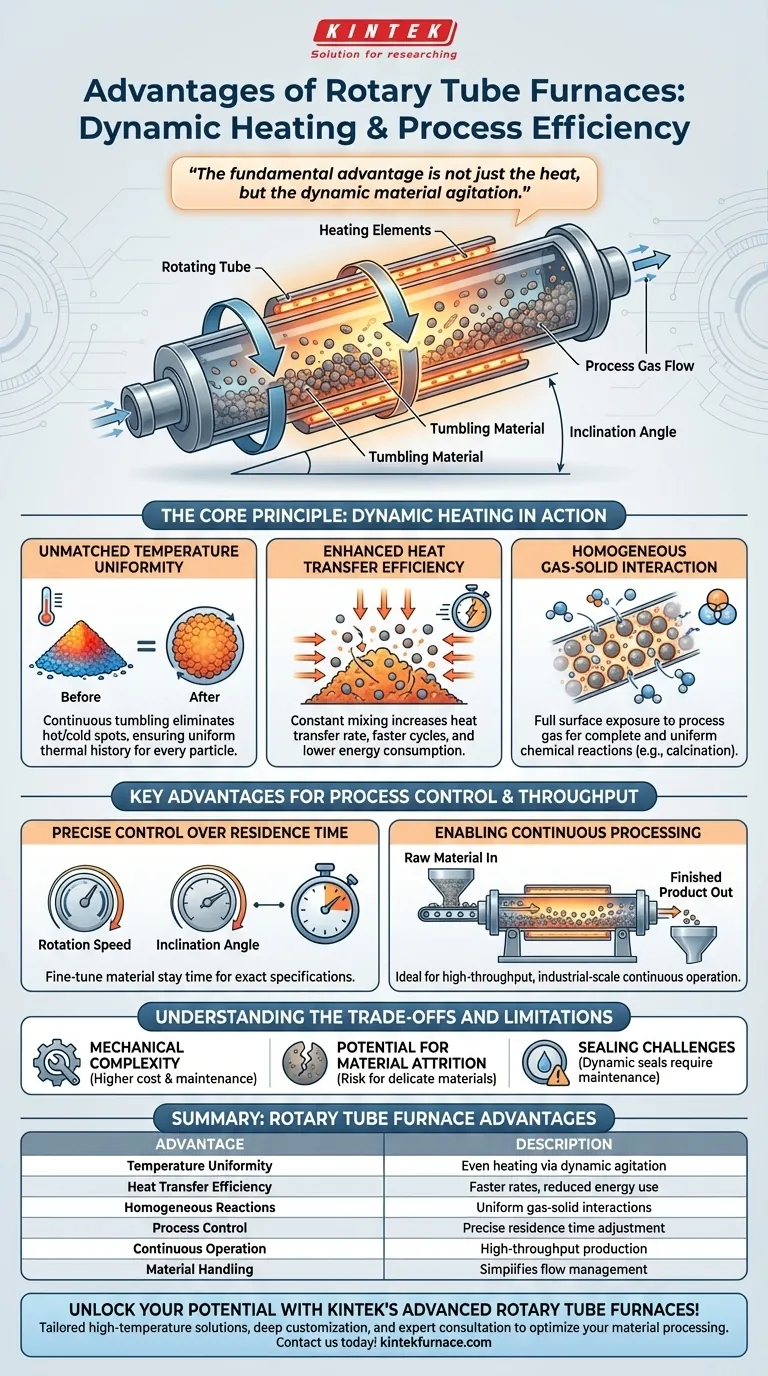

The Core Principle: Dynamic Heating in Action

Unlike a static furnace where material sits motionless, a rotary tube furnace uses a slowly rotating cylindrical tube, often inclined at a slight angle. This design is the source of its primary benefits.

Achieving Unmatched Temperature Uniformity

In a static process, the material at the edges heats faster than the material in the center, creating significant temperature gradients and inconsistent results.

The tumbling motion of a rotary furnace continuously exposes every particle to the heat source and the surrounding process atmosphere. This eliminates hot spots and cold spots, ensuring a highly uniform temperature distribution throughout the entire batch.

Enhancing Heat Transfer Efficiency

The constant mixing action dramatically increases the rate of heat transfer into the material. This allows for faster processing cycles and shorter residence times compared to static methods.

This efficiency translates directly into lower energy consumption per unit of material processed, making it a more economical choice for many applications.

Ensuring Homogeneous Gas-Solid Interaction

For processes like calcination, oxidation, or roasting, uniform exposure to a specific gas atmosphere is critical.

The rotary motion guarantees that the entire surface area of the material consistently interacts with the process gas, leading to a more complete and homogeneous chemical reaction.

Key Advantages for Process Control & Throughput

The mechanical design of a rotary furnace provides a level of control and efficiency that is difficult to achieve in other systems.

Precise Control Over Residence Time

The combination of the tube's rotation speed and its angle of inclination gives you precise control over how long the material stays within the heated zone.

This allows you to fine-tune the process to meet exact specifications for a wide range of materials and desired outcomes.

Enabling Continuous Processing

While they can be used for batch work, rotary furnaces excel at continuous operation. Raw material can be fed into one end and the finished product discharged from the other, enabling high-throughput production.

This makes them ideal for industrial-scale applications where consistent output and minimal downtime are paramount.

Streamlining Material Handling

For powders and granular materials, the self-mixing nature of the furnace minimizes the need for extensive pre-processing or manual handling. The system effectively manages the material flow internally.

Understanding the Trade-offs and Limitations

No technology is a universal solution. The advantages of a rotary design come with specific trade-offs that must be considered.

Mechanical Complexity

The drive motors, rotating seals, and support structures add a layer of mechanical complexity not present in a simple static tube furnace. This translates to higher initial costs and more demanding maintenance requirements.

Potential for Material Attrition

The constant tumbling, while beneficial for heating, can cause mechanical wear and tear on the material itself. This phenomenon, known as attrition, can be detrimental for friable or delicate crystalline materials that may break down into finer dust.

Sealing Challenges

Maintaining a perfectly hermetic seal for high-vacuum or controlled-pressure atmospheres can be more challenging with a rotating tube compared to a static one. The dynamic seals are critical components that require careful design and maintenance to prevent leaks.

Is a Rotary Tube Furnace Right for Your Application?

Choosing the correct furnace depends entirely on your process goals.

- If your primary focus is high-throughput industrial production: The continuous processing capability and energy efficiency of a rotary tube furnace are unmatched for materials like cement clinker, iron ore, or alumina.

- If your primary focus is absolute process uniformity: For synthesizing or treating powders where every particle must have the exact same thermal history, the dynamic heating of a rotary furnace is a critical advantage.

- If your primary focus is processing delicate materials or requiring an ultra-high vacuum: The risk of material attrition and the challenges of dynamic sealing might make a static tube furnace a more reliable and simpler choice.

Ultimately, the rotary tube furnace is a powerful tool designed to deliver exceptional consistency and efficiency for the thermal processing of free-flowing materials.

Summary Table:

| Advantage | Description |

|---|---|

| Temperature Uniformity | Ensures even heating through dynamic material agitation, eliminating hot and cold spots. |

| Heat Transfer Efficiency | Increases heat transfer rates, reducing energy consumption and processing times. |

| Homogeneous Reactions | Promotes uniform gas-solid interactions for complete chemical processes like calcination. |

| Process Control | Allows precise adjustment of residence time via rotation speed and tube inclination. |

| Continuous Operation | Enables high-throughput production with minimal downtime for industrial applications. |

| Material Handling | Simplifies flow management for powders and granules, reducing manual intervention. |

Unlock the full potential of your thermal processes with KINTEK's advanced rotary tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and consistency. Ready to optimize your material processing? Contact us today for expert consultation and discover how our solutions can drive your success!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency