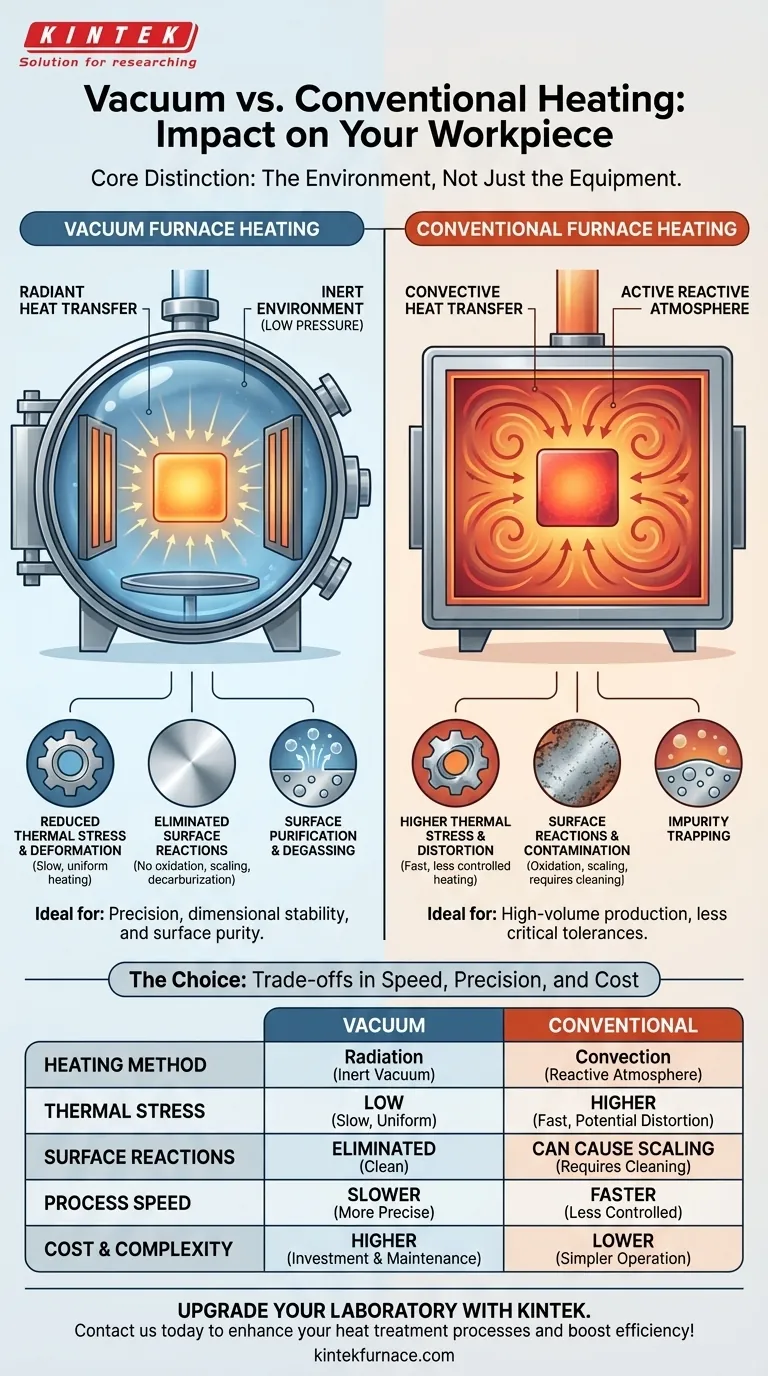

In short, heating in a vacuum furnace affects a workpiece by providing a slow, highly uniform, and contamination-free process. This minimizes internal thermal stress to reduce distortion and eliminates surface reactions like oxidation, resulting in a cleaner, higher-integrity part compared to faster, less controlled conventional heating methods.

The core distinction is not merely the equipment, but the environment itself. Conventional heating subjects a workpiece to a reactive atmosphere, trading precision for speed, whereas vacuum heating prioritizes material purity and dimensional stability by controlling the environment first.

The Fundamental Difference: Heat Transfer

The most significant distinction between vacuum and conventional furnaces lies in how they transfer thermal energy to the workpiece. This mechanism dictates the outcome of the entire process.

Conventional Furnaces: Convection in an Active Atmosphere

Conventional heat treatment typically occurs in the presence of air or a controlled gas mixture.

Heat is transferred primarily through convection, where heated gas circulates around the workpiece. While this can be relatively fast, it introduces reactive elements like oxygen.

Vacuum Furnaces: Radiation in an Inert Environment

A vacuum furnace first removes the atmosphere from a sealed chamber, creating a low-pressure environment.

Heat is then transferred almost exclusively through radiation from heating elements (often graphite or ceramic). This radiant energy travels unimpeded through the vacuum to the workpiece, ensuring a highly uniform and predictable heating cycle without contaminants.

Impact on Workpiece Integrity and Quality

The heating environment directly influences the final mechanical and metallurgical properties of the component. A vacuum provides several distinct advantages.

Reduced Thermal Stress and Deformation

Because heating in a vacuum is slower and more uniform, the temperature difference between the surface and the core of the workpiece remains small.

This minimizes the buildup of internal thermal stress, which is the primary cause of warping and distortion during heat treatment. The result is a more dimensionally stable part.

Elimination of Surface Reactions

The absence of oxygen and other reactive gases prevents undesirable surface reactions.

This means no oxidation (scaling), no decarburization, and no carburization, preserving the surface chemistry and integrity of the material. Conventional methods often require secondary cleaning operations like sandblasting to remove scale.

Surface Purification and Degassing

The vacuum environment actively works to clean the workpiece.

It provides a degassing function, pulling trapped gases like hydrogen and nitrogen out of the material. It also helps vaporize and remove surface oils or phosphorus residues, producing a bright, clean surface straight from the furnace.

Understanding the Trade-offs

While vacuum heating offers superior quality, it is not the universal solution. The choice involves clear trade-offs between process goals and operational constraints.

Speed vs. Precision

Conventional heating is generally faster, making it suitable for high-volume production where minor surface imperfections or slight distortion are acceptable.

Vacuum heating is a slower, more deliberate process. It is chosen when precision, surface finish, and final material properties are critical and cannot be compromised.

Equipment and Operational Complexity

Vacuum furnaces are complex systems involving pumps, seals, and precise controls to maintain the low-pressure environment. This translates to a higher initial investment and more rigorous maintenance.

Conventional atmosphere furnaces are often simpler in design and operation, resulting in lower capital and operational costs.

Process Suitability

Vacuum furnaces excel at processes like hardening, tempering, annealing, and brazing where a clean, inert environment is paramount.

However, some treatments, such as traditional gas carburizing, fundamentally require an active carbon-rich atmosphere and are performed in specialized atmosphere furnaces.

Making the Right Choice for Your Application

Your final decision should be guided by the non-negotiable requirements of your component's end-use.

- If your primary focus is dimensional stability and minimal distortion: Vacuum heating is the superior choice due to its slow, uniform thermal transfer.

- If your primary focus is surface purity and preventing oxidation: Vacuum is the definitive solution, as it removes the reactive gases that cause surface degradation.

- If your primary focus is high-volume production with less critical tolerances: Conventional heating often provides a more cost-effective and faster path.

Understanding these core differences empowers you to select a heat treatment process that protects the integrity and enhances the performance of your final component.

Summary Table:

| Aspect | Vacuum Furnace Heating | Conventional Heating |

|---|---|---|

| Heating Method | Radiation in inert vacuum | Convection in reactive atmosphere |

| Thermal Stress | Low, due to slow and uniform heating | Higher, leading to potential distortion |

| Surface Reactions | Eliminates oxidation, decarburization | Can cause scaling, requires cleaning |

| Process Speed | Slower, more precise | Faster, less controlled |

| Cost and Complexity | Higher initial investment and maintenance | Lower cost, simpler operation |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, delivering contamination-free heating, reduced distortion, and superior material integrity. Contact us today to discuss how we can enhance your heat treatment processes and boost efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability