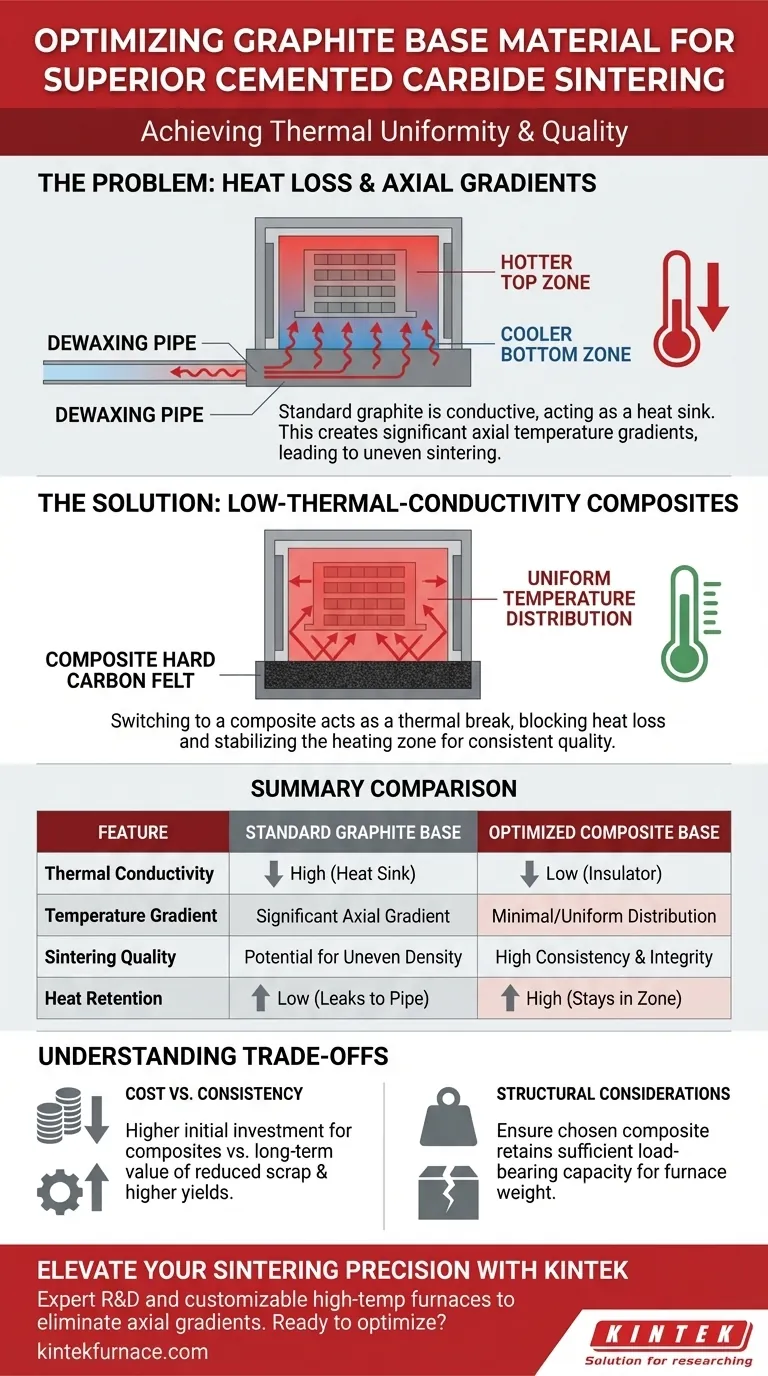

Optimizing the graphite base material is a critical step in achieving thermal uniformity during the cemented carbide sintering process. By replacing standard graphite bases with low-thermal-conductivity materials, you effectively block heat loss pathways connected to the dewaxing pipe, ensuring that temperature distribution remains consistent across the entire furnace load.

Heat loss through the furnace base creates axial temperature gradients that compromise sintering integrity. switching to a low-thermal-conductivity composite acts as a thermal break, raising the temperature in the lower zones and guaranteeing consistent quality for every component in the batch.

The Mechanics of Heat Loss

The Vulnerability of the Base

In a typical vacuum sintering furnace, the graphite base is structurally connected to the dewaxing pipe.

While necessary for the process, this connection creates a conductive path for heat to escape the heating zone.

The Problem with Standard Graphite

Standard graphite is relatively thermally conductive.

Consequently, it acts as a heat sink, drawing energy away from the bottom of the furnace load and channeling it out through the dewaxing system.

Creating an Axial Gradient

This heat loss results in a significant axial temperature gradient.

The bottom of the heating zone becomes cooler than the top, leading to uneven sintering where parts at the bottom may not achieve full density or the desired microstructure.

Material Optimization Strategy

Switching to Composite Materials

To counter this, the standard graphite base should be replaced with a material possessing low thermal conductivity.

Composite hard carbon felt is the primary recommendation for this application.

Blocking the Thermal Leak

This composite material acts as an effective insulator rather than a conductor.

It blocks the heat loss path to the dewaxing pipe, retaining energy within the heating zone where it belongs.

Stabilizing the Heating Zone

The immediate result is an increase in the temperature at the bottom of the heating zone.

This equalizes the temperature profile, significantly reducing the axial gradient and ensuring the thermal environment is uniform from top to bottom.

Understanding the Trade-offs

Cost vs. Consistency

High-performance insulating materials like composite hard carbon felt generally command a higher price point than standard graphite components.

You must weigh this initial investment against the long-term value of reduced scrap rates and higher process yields.

Structural Considerations

While excellent for insulation, some composite felts may have different structural properties compared to solid graphite blocks.

It is essential to ensure the chosen material retains sufficient load-bearing capacity for your specific furnace weight requirements.

Making the Right Choice for Your Goal

To optimize your sintering furnace effectively, consider your specific production priorities:

- If your primary focus is Precision Quality: Prioritize composite hard carbon felt bases to minimize temperature gradients and ensure uniform microstructure across the entire load.

- If your primary focus is Cost Management: Evaluate if your current scrap rate justifies the upgrade; if the axial gradient is causing measurable defects, the material upgrade will likely pay for itself.

Optimizing the base material transforms the furnace floor from a heat sink into a thermal stabilizer, securing the consistency of your final product.

Summary Table:

| Feature | Standard Graphite Base | Optimized Composite Base |

|---|---|---|

| Thermal Conductivity | High (acts as a heat sink) | Low (acts as an insulator) |

| Temperature Gradient | Significant axial gradient | Minimal/Uniform distribution |

| Sintering Quality | Potential for uneven density | High consistency and integrity |

| Heat Retention | Low; heat leaks to dewaxing pipe | High; energy stays in heating zone |

| Best For | Budget-focused operations | Precision & high-yield production |

Elevate Your Sintering Precision with KINTEK

Don't let heat loss compromise your product integrity. KINTEK provides expert R&D and manufacturing of high-performance lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to solve your thermal uniformity challenges. Our specialized graphite and composite solutions are designed to eliminate axial gradients and maximize your process yield.

Ready to optimize your furnace performance? Contact KINTEK today for a custom consultation and see how our tailored high-temperature solutions can transform your lab's efficiency.

Visual Guide

References

- Mao Li, Hesong Li. Numerical simulation of the heating process in a vacuum sintering electric furnace and structural optimization. DOI: 10.1038/s41598-024-81843-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What is the role of industrial-grade vacuum furnaces in IN718 heat treatment? Unlock Superior Alloy Performance

- What processes are hot wall vacuum furnaces used for? Ideal for precise, uniform low-temperature heat treatments

- How does an ultra-high temperature graphitization furnace enhance thermal conductivity? | KINTEK Advanced Solutions

- What vacuum level is required for AlCrSiWN coating deposition? Achieving Peak Purity and Adhesion

- What role do vacuum annealing furnaces play in optical material processing? Enhance Clarity and Performance for Your Optics

- How does a vacuum or protective atmosphere reduce oxidation in molten metals? Prevent Oxide Inclusions for Stronger Metals

- How does a laboratory vacuum oven function in the drying step of polyimide precursor fibers? Enhance Material Quality

- What are the advantages of vacuum hardening? Achieve Superior Dimensional Accuracy and Cleanliness