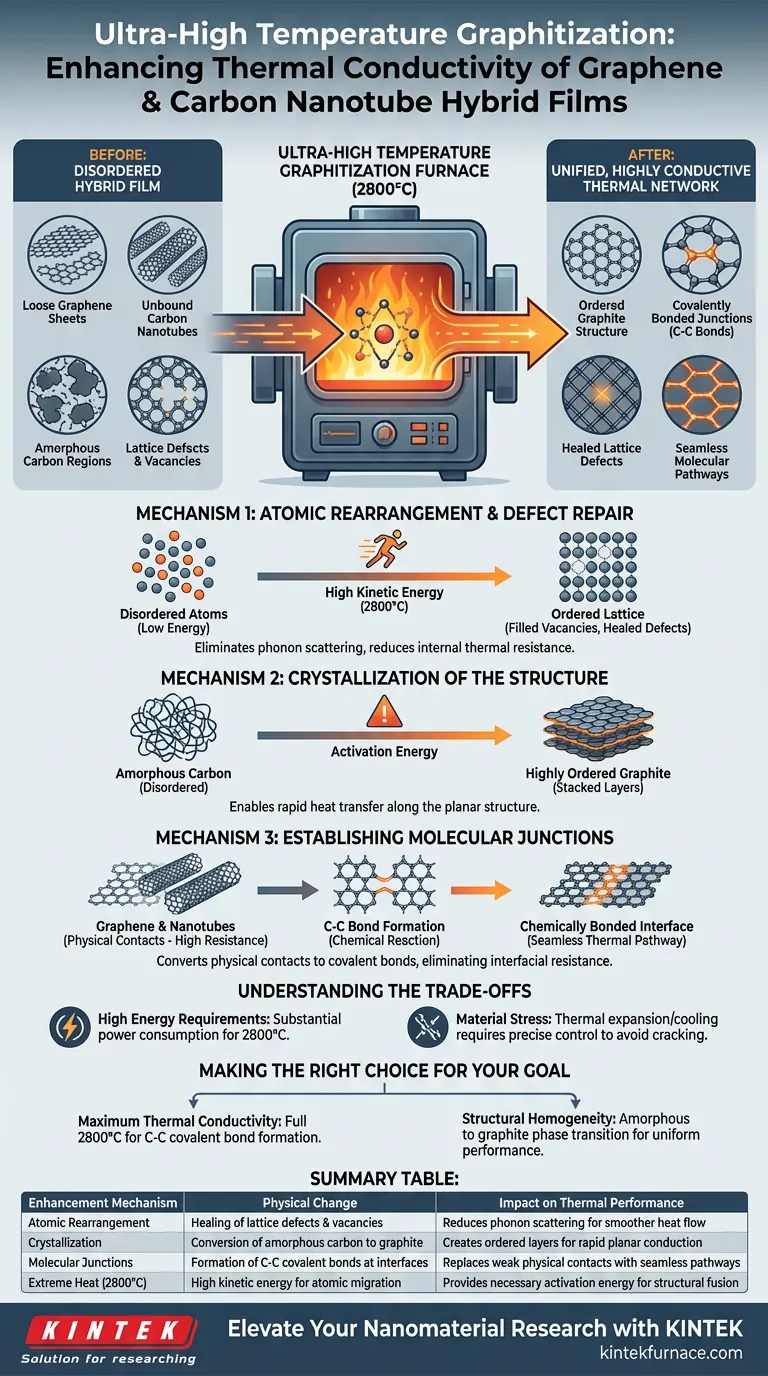

The ultra-high temperature graphitization furnace enhances thermal conductivity by fundamentally restructuring the material's atomic architecture at 2800 degrees Celsius. This extreme thermal energy drives the rearrangement of carbon atoms to eliminate structural imperfections and transforms disordered amorphous carbon into a highly crystalline graphite structure. Crucially, it fuses graphene and carbon nanotubes together by forming strong C-C covalent bonds at their contact points, replacing weak physical contacts with seamless molecular pathways for heat transfer.

By subjecting hybrid films to extreme thermal energy, the furnace solves the critical problem of interfacial resistance. It physically "welds" graphene and carbon nanotubes at the molecular level, converting a loose assembly of particles into a unified, highly conductive thermal network.

Mechanism 1: Atomic Rearrangement and Defect Repair

Driving Atomic Mobility

At the operating temperature of 2800 degrees Celsius, carbon atoms gain significant kinetic energy.

This energy allows atoms to break free from energetically unfavorable positions. They are driven to migrate within the material lattice.

Eliminating Lattice Defects

As the atoms rearrange, they fill vacancies and correct structural irregularities known as lattice defects.

Removing these defects is essential because imperfections scatter heat-carrying phonons. By "healing" the lattice, the furnace significantly reduces internal thermal resistance.

Mechanism 2: Crystallization of the Structure

converting Amorphous Carbon

Raw hybrid films often contain regions of amorphous carbon, where atoms are arranged without long-range order.

This disordered state acts as a bottleneck for thermal conductivity. It disrupts the efficient transfer of vibrational energy.

Creating Highly Ordered Graphite

The furnace provides the activation energy required to transform this amorphous carbon into a highly ordered graphite structure.

In this graphitic state, carbon layers stack precisely. This alignment allows heat to travel rapidly along the plane of the material.

Mechanism 3: Establishing Molecular Junctions

The Challenge of Contact Points

In a standard hybrid mixture, graphene sheets and carbon nanotubes merely touch each other.

These physical contact points act as barriers to heat flow. Thermal energy struggles to jump across the gaps between distinct nanomaterials.

Formation of C-C Covalent Bonds

The most critical function of the furnace is promoting the formation of C-C covalent bonds.

The high temperature catalyzes a chemical reaction at the interface where graphene meets a nanotube.

Creating Thermal Pathways

Instead of distinct materials touching, they become chemically bonded.

This establishes continuous thermal conduction pathways at the molecular level. Heat can now flow unobstructed from the planar graphene into the tubular nanotubes.

Understanding the Trade-offs

High Energy Requirements

Achieving and maintaining 2800°C requires substantial power consumption.

This makes the process energy-intensive and potentially costly compared to lower-temperature annealing methods.

Material Stress

The extreme thermal expansion and subsequent cooling can introduce stress to the material.

If the heating and cooling ramp rates are not precisely controlled, the film could suffer from micro-cracking or mechanical degradation.

Making the Right Choice for Your Goal

To maximize the utility of graphitization for your hybrid films, consider your specific performance targets:

- If your primary focus is Maximum Thermal Conductivity: Ensure the process reaches the full 2800°C to guarantee the formation of C-C covalent bonds, as lower temperatures may only repair lattice defects without fusing the interfaces.

- If your primary focus is Structural Homogeneity: Use the furnace to drive the phase transition from amorphous carbon to graphite, ensuring uniform performance across the entire film surface.

Ultimately, the value of this furnace lies in its ability to transform a physical mixture of nanomaterials into a chemically unified, high-performance thermal conductor.

Summary Table:

| Enhancement Mechanism | Physical Change | Impact on Thermal Performance |

|---|---|---|

| Atomic Rearrangement | Healing of lattice defects and vacancies | Reduces phonon scattering for smoother heat flow |

| Crystallization | Conversion of amorphous carbon to graphite | Creates ordered layers for rapid planar conduction |

| Molecular Junctions | Formation of C-C covalent bonds at interfaces | Replaces weak physical contacts with seamless pathways |

| Extreme Heat (2800°C) | High kinetic energy for atomic migration | Provides necessary activation energy for structural fusion |

Elevate Your Nanomaterial Research with KINTEK

Unlock the full potential of your carbon composites with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and precision manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, including specialized high-temp furnaces capable of reaching the extreme temperatures required for graphitization.

Whether you are fusing graphene and nanotubes or developing next-generation films, our customizable systems are designed to meet your unique lab requirements. Contact us today to discuss how our high-temperature technology can transform your material performance.

Visual Guide

References

- Yu-Ze Xing, Cheng‐Meng Chen. Revealing the essential effect mechanism of carbon nanotubes on the thermal conductivity of graphene film. DOI: 10.1039/d3tc03840h

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What industries commonly use vacuum furnaces? Essential for Aerospace, Medical, Automotive, and Electronics

- Why are vacuum sintering furnaces important in manufacturing? Unlock Purity, Strength, and Precision

- What are the advantages of using a vacuum drying oven in the phosphor preparation process? Achieve Higher Purity Today

- Why is a laboratory oven used for borated nanodiamond synthesis? Ensure Pure Chemical Surface Growth

- How does a vacuum sintering furnace facilitate the final densification of 3D-printed fused silica glass? Expert Guide

- What effect does increasing quenching gas pressure have? Optimize Heat Treatment with High-Pressure Gas Quenching

- Why is a vacuum oven used for drying ionogels? Preserve Structural Integrity for Precise Electron Microscopy

- What role does a vacuum drying oven play in high-entropy alloy powder preparation? Ensure Peak Sintering Density