Industrial-grade vacuum and atmosphere furnaces act as the definitive mechanism for determining the final mechanical properties of Inconel 718 (IN718) components. They provide the rigorous environment necessary to execute specific thermal cycles—homogenization, solution treatment, and aging—that transform the "as-manufactured" material into a reliable, high-performance alloy.

Core Takeaway These furnaces do not merely heat the material; they fundamentally reconfigure the microstructure by dissolving harmful phases and relieving residual stress in a protected environment. This transformation is the primary driver for achieving the high fatigue strength, dimensional stability, and hardness required for industrial IN718 applications.

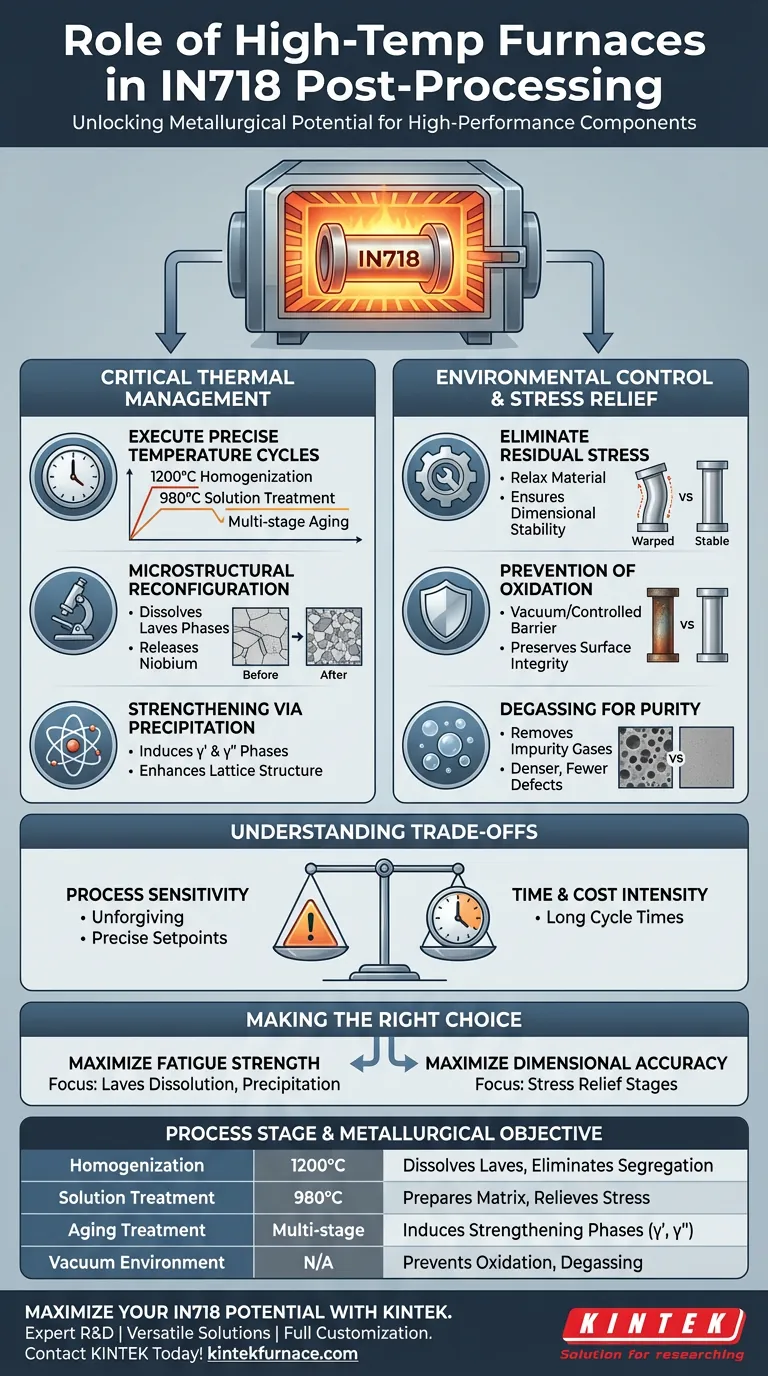

The Critical Role of Thermal Management

Executing Precise Temperature Cycles

The primary function of these furnaces is to deliver exact temperature profiles that standard ovens cannot maintain.

According to industry standards, this typically involves a homogenization cycle at 1200°C, followed by a solution treatment at 980°C, and concluding with multi-stage aging treatments.

Microstructural Reconfiguration

The high temperatures are not arbitrary; they are designed to repair the microstructure.

During fabrication, IN718 often develops harmful Laves phases. The furnace's ability to hold specific temperatures facilitates the dissolution of these phases.

Strengthening via Precipitation

Dissolving the Laves phases releases vital elements, specifically Niobium.

Once released, these elements are free to induce the precipitation of strengthening phases ($\gamma'$ and $\gamma''$) and grain boundary $\delta$ phases. This chemical reorganization significantly enhances the lattice structure's microhardness and compressive strength.

Environmental Control and Stress Relief

Eliminating Residual Stress

IN718 components, particularly those created via additive manufacturing, accumulate significant residual stress during formation.

The furnace cycles effectively relax the material, eliminating these internal forces. This ensures the component maintains its shape (dimensional stability) rather than warping or cracking under load.

Prevention of Oxidation

At temperatures exceeding 900°C, metals are highly reactive to oxygen.

Vacuum or controlled atmosphere furnaces create a barrier against the outside air. This prevents oxidation and decarburization, preserving the surface integrity and corrosion resistance of the component.

Degassing for Purity

Beyond preventing oxidation, a vacuum environment actively removes impurity gases trapped within the material.

This results in a denser, purer product with fewer internal defects, which is directly correlated to improved mechanical performance.

Understanding the Trade-offs

Process Sensitivity

While these furnaces offer superior control, the process is unforgiving.

Deviating from the precise temperature setpoints (e.g., missing the 980°C solution window) can result in incomplete phase transformation or grain growth, rendering the part out of spec.

Time and Cost Intensity

These are not rapid processes.

The requirement for multiple stages—heating, holding for dissolution, and controlled cooling rates—means cycle times are long. This makes the post-processing phase a significant factor in the total cost and lead time of IN718 components.

Making the Right Choice for Your Goal

To maximize the value of your heat treatment process, align your furnace operations with your specific engineering requirements:

- If your primary focus is Fatigue Strength: Prioritize cycles that ensure complete dissolution of Laves phases and precise precipitation of $\gamma''$ phases to maximize lattice durability.

- If your primary focus is Dimensional Accuracy: Ensure your cycle emphasizes the stress relief stages to prevent warping in complex geometries during subsequent machining or use.

Ultimately, the furnace is not just a heating tool, but a synthesis chamber that unlocks the full metallurgical potential of Inconel 718.

Summary Table:

| Process Stage | Typical Temperature | Primary Metallurgical Objective |

|---|---|---|

| Homogenization | 1200°C | Dissolves Laves phases & eliminates chemical segregation |

| Solution Treatment | 980°C | Prepares matrix for precipitation & relieves residual stress |

| Aging Treatment | Multi-stage | Induces strengthening phases (γ' and μ'') for hardness |

| Vacuum Environment | N/A | Prevents oxidation, decarburization, and ensures degassing |

Maximize the Potential of Your IN718 Components

Don't let improper thermal management compromise your material integrity. KINTEK provides industry-leading high-temperature vacuum and atmosphere furnaces specifically designed for the rigorous demands of superalloy post-processing.

Why partner with KINTEK?

- Expert R&D: Our systems are engineered to provide the precise temperature uniformity required to dissolve Laves phases and ensure dimensional stability.

- Versatile Solutions: Choose from Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your specific production scale.

- Full Customization: We adapt our technology to meet your unique metallurgical specifications and additive manufacturing workflows.

Ensure your components achieve maximum fatigue strength and purity. Contact KINTEK today to discuss your heat treatment needs!

Visual Guide

References

- Lakshmi Ramineni, Ala Qattawi. Residual Stress Mapping in Heat-Assisted Additive Manufacturing of IN 718: An X-Ray Diffraction Study. DOI: 10.1007/s11665-024-09269-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does a vacuum annealing furnace reduce pollution? Achieve Cleaner Metal Processing with Zero Oxidation

- What is the heat treatment in a vacuum oven? Achieve Superior Surface & Material Integrity

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- Why are vacuum chamber furnaces essential for industrial heat treatment? Ensure Contaminant-Free Precision

- How does a vacuum furnace differ from conventional heat treatment configurations? Discover Key Benefits for Superior Material Quality

- How do thermal imagers and hybrid AI models facilitate leak detection? 92% Accuracy in Industrial Furnaces

- What environmental controls does a vacuum diffusion furnace provide? Master High-Vacuum Heat Treatment

- Why is a vacuum oven necessary for drying ZnO-Co3O4 electrode slurries? Preserve Material Integrity at 60°C