At its core, a vacuum furnace differs from a conventional furnace by fundamentally changing the environment in which a part is heated. Instead of heating a component in the open air, a vacuum furnace first removes the atmosphere from a sealed chamber and then performs the entire heat treatment cycle—heating, soaking, and quenching—within that controlled, contamination-free environment.

The crucial distinction is not merely the heating method, but the control of the atmosphere. A conventional furnace exposes parts to reactive gases like oxygen, while a vacuum furnace eliminates them, preventing surface reactions and enabling a level of precision that is impossible to achieve in an open-air system.

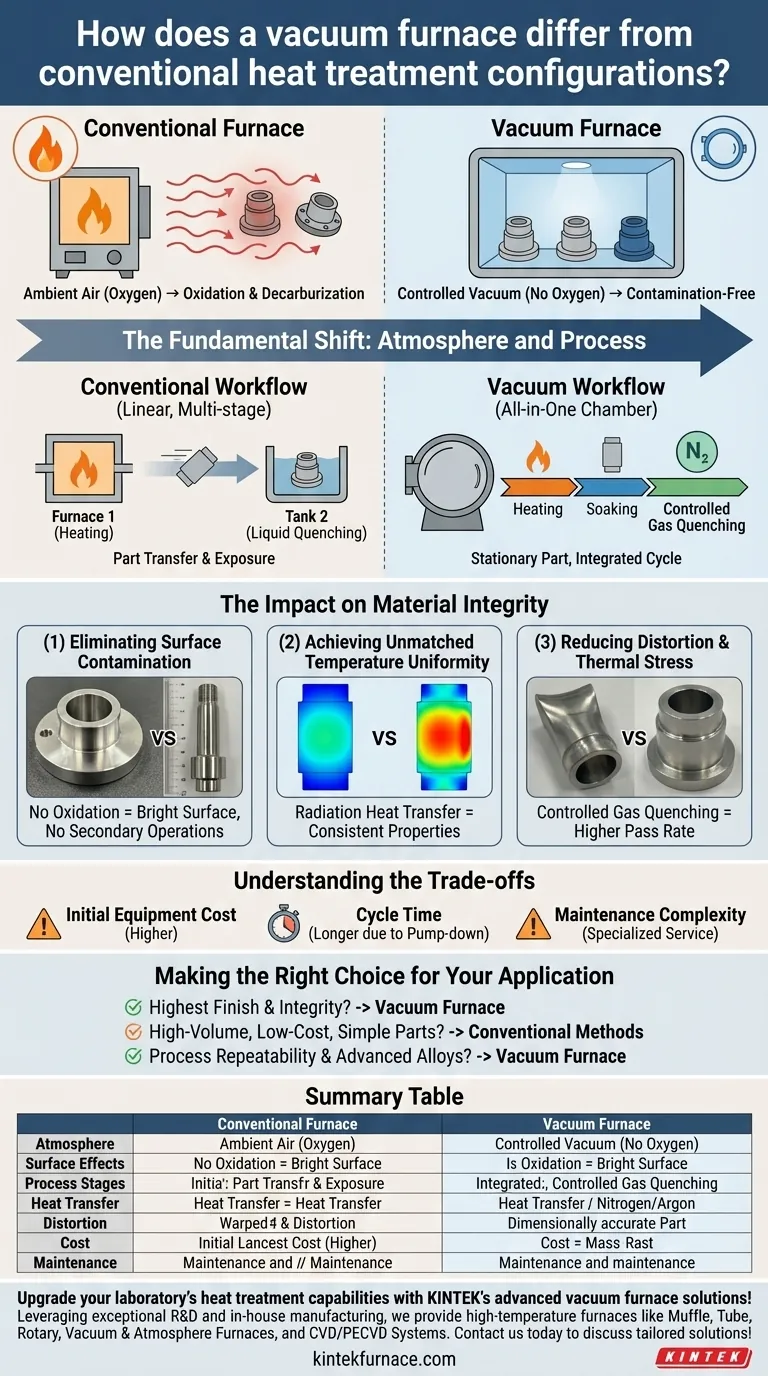

The Fundamental Shift: Atmosphere and Process

The transition from conventional to vacuum heat treatment represents a move from a linear, multi-stage process to an integrated, all-in-one system. This shift is driven by two key operational differences.

From Open Air to a Controlled Vacuum

A conventional furnace operates in ambient air, which contains about 21% oxygen. When metal is heated in the presence of oxygen, it leads to oxidation (scaling) and decarburization (the loss of carbon from the surface), both of which degrade the material's surface quality and mechanical properties.

A vacuum furnace solves this by using pumps to evacuate nearly all the air from a sealed chamber before heating begins. This creates a pure, non-reactive environment for the workpiece.

From Separate Stages to a Single Chamber

The conventional workflow is linear and requires physically moving parts between equipment. A component is heated in one furnace, then transferred through the air to a separate tank for oil or water quenching.

A vacuum furnace is an all-in-one solution. The part remains stationary inside the sealed chamber for the entire process, including the cooling or quenching cycle, which is typically performed by backfilling the chamber with a high-pressure, inert gas like nitrogen or argon.

The Impact on Material Integrity

By controlling the atmosphere, a vacuum furnace delivers superior results that are difficult or impossible to achieve with conventional methods. This directly translates to higher quality and more reliable components.

Eliminating Surface Contamination

The most significant benefit of a vacuum is the complete prevention of oxidation. Parts emerge from the furnace with a bright, clean surface, free of scale or discoloration.

This eliminates the need for costly and time-consuming secondary operations like sandblasting, chemical cleaning, or machining to remove a damaged surface layer.

Achieving Unmatched Temperature Uniformity

In a vacuum, heat transfer occurs primarily through radiation, not convection. This lack of air currents allows for exceptionally uniform and precise heating across the entire part, minimizing hot or cold spots.

This level of control is critical for processing sensitive alloys and complex geometries, ensuring consistent metallurgical properties throughout the component.

Reducing Distortion and Thermal Stress

Uniform heating combined with controlled gas quenching significantly reduces the thermal shock and stress a part experiences. This results in far less distortion and warping compared to the aggressive liquid quenching often used in conventional processes.

The outcome is a higher pass rate, with more parts meeting strict dimensional tolerances without the need for rework.

Understanding the Trade-offs

While vacuum technology offers clear advantages, it is essential to understand its limitations to make an informed decision.

Initial Equipment Cost

Vacuum furnaces represent a significant capital investment compared to most conventional atmospheric furnaces. The complexity of the vacuum chamber, pumping systems, and integrated controls contributes to a higher initial purchase price.

Cycle Time Considerations

While the heating and cooling cycles are very efficient, the overall process time can be longer. The time required to pump the chamber down to the required vacuum level and backfill it for quenching adds steps that do not exist in a conventional process.

Maintenance Complexity

Maintaining a vacuum furnace is more demanding than a simple atmospheric furnace. Seals, pumps, and control systems require specialized knowledge and regular service to ensure leak-free performance and process reliability.

Making the Right Choice for Your Application

Choosing between a vacuum and a conventional furnace depends entirely on your technical requirements, quality standards, and budget.

- If your primary focus is the highest possible surface finish and material integrity: A vacuum furnace is the definitive choice for eliminating oxidation and ensuring process purity.

- If your primary focus is high-volume, low-cost processing of simple parts: Conventional methods may remain more cost-effective, especially if a scaled or decarburized surface is acceptable or can be easily rectified.

- If your primary focus is process repeatability and treating advanced or sensitive alloys: The precise, automated control of a vacuum furnace is essential for achieving consistent, high-performance results.

Ultimately, investing in vacuum technology is a decision to prioritize quality, precision, and process control over all other factors.

Summary Table:

| Aspect | Vacuum Furnace | Conventional Furnace |

|---|---|---|

| Atmosphere | Controlled vacuum, no oxygen | Ambient air with oxygen |

| Surface Effects | No oxidation or decarburization | Oxidation and decarburization occur |

| Process Stages | All-in-one chamber (heating, soaking, quenching) | Linear, multi-stage with part transfers |

| Heat Transfer | Primarily radiation for uniformity | Convection with potential hot/cold spots |

| Distortion | Reduced due to controlled gas quenching | Higher risk from aggressive liquid quenching |

| Cost | Higher initial investment | Lower initial cost |

| Maintenance | More complex, requires specialized service | Simpler and less demanding |

Upgrade your laboratory's heat treatment capabilities with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering contamination-free processing, superior temperature control, and reduced distortion for high-quality results. Don't compromise on precision—contact us today to discuss how our tailored solutions can enhance your material integrity and efficiency!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What technological features enhance the efficiency of vacuum furnaces? Boost Performance with Advanced Control & Energy Savings

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability