At its core, a vacuum annealing furnace reduces pollution by fundamentally changing the environment in which the metal is heated. By removing atmospheric gases like oxygen and nitrogen, it prevents the chemical reactions—chiefly oxidation—that contaminate the metal's surface, resulting in a cleaner workpiece and eliminating the need for secondary, pollution-generating cleaning processes.

The term "pollution" in vacuum annealing refers less to emissions and more to the prevention of surface contamination on the material itself. By creating a high-vacuum environment, the furnace stops oxidation and other reactions before they can begin.

The Core Principle: Removing the Reactive Atmosphere

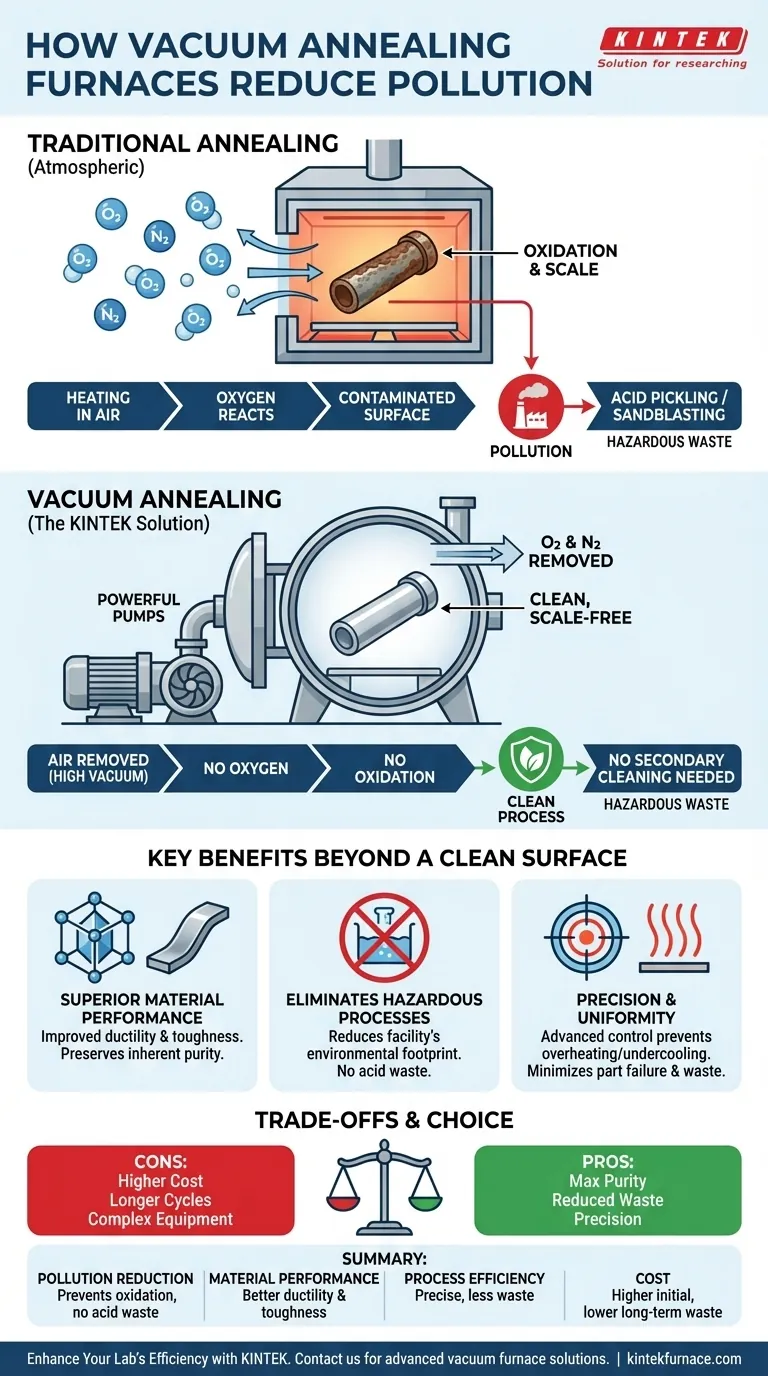

To understand the benefits of a vacuum, we must first understand what happens in a traditional furnace. The core innovation of vacuum annealing is the elimination of the primary source of contamination: the air itself.

How Traditional Annealing Works

In a standard annealing process, a metal part is heated, held at a specific temperature, and then cooled. When done in the presence of air, the oxygen aggressively reacts with the hot metal surface, creating a layer of oxide scale.

This oxide layer is a form of contamination that degrades the surface finish and can negatively impact the material's properties.

The Role of the Vacuum

A vacuum annealing furnace first seals the workpiece in an isolated chamber and then uses powerful pumps to remove the air, creating a high-vacuum environment.

This process removes the reactive elements—primarily oxygen and nitrogen—that would otherwise interact with the material at high temperatures. The workpiece is then heated and cooled within this controlled, inert space.

Preventing Oxidation and Contamination

With no oxygen present, oxidation simply cannot occur. The metal's surface remains clean, bright, and uncontaminated throughout the heating and cooling cycle.

This directly preserves the material's inherent purity and performance characteristics, as the surface is not altered by unwanted chemical reactions.

Benefits Beyond a Cleaner Surface

Preventing surface contamination has profound effects on the final product, improving not just its appearance but its fundamental mechanical properties. This process control also reduces waste from secondary operations.

Superior Material Performance

Operating in a vacuum allows for highly effective stress relief and recrystallization. The result is an improved crystal structure, which enhances the material's plasticity (ductility) and toughness.

This clean processing environment ensures that the performance gains from annealing are not compromised by surface impurities.

Eliminating Hazardous Secondary Processes

Because parts emerge from a vacuum furnace clean and scale-free, it often eliminates the need for post-annealing cleaning steps like sandblasting or acid pickling.

These secondary processes are themselves significant sources of pollution, with acid baths creating hazardous chemical waste. By producing a clean part directly, the vacuum furnace indirectly reduces the facility's overall environmental footprint.

Precision and Uniformity

Advanced temperature control systems allow for extremely precise and uniform heating within the vacuum chamber. This prevents overheating or undercooling, ensuring that every part in a batch receives the exact same treatment.

This high degree of repeatability minimizes part failure and material waste, contributing to a more efficient and less wasteful operation.

Understanding the Trade-offs

While highly effective, vacuum annealing is not the default choice for every application. The technology involves specific trade-offs in cost, complexity, and cycle time that must be considered.

Equipment and Operating Costs

Vacuum furnaces are complex machines involving sealed chambers, robust pumping systems, and sophisticated controls. This results in a higher initial investment and potentially higher maintenance costs compared to simpler atmospheric furnaces.

Cycle Times and Throughput

Achieving a high vacuum before the heating cycle can begin adds time to the overall process. For high-volume, low-margin parts, this longer cycle time may impact overall production throughput.

Application Suitability

For materials where surface oxidation is not a critical concern or for applications where a subsequent machining step will remove the outer surface anyway, the added expense of vacuum processing may not be justifiable.

Making the Right Choice for Your Goal

Selecting the correct annealing process requires aligning the technology's capabilities with your most important project outcome.

- If your primary focus is maximum material purity and a flawless surface finish: Vacuum annealing is the definitive choice, as it is the only way to completely prevent oxidation.

- If your primary focus is reducing hazardous waste from post-processing: Vacuum annealing is highly effective, as it produces a clean part that does not require secondary acid cleaning.

- If your primary focus is cost-effective stress relief for non-critical components: Traditional atmospheric annealing may provide a more economical solution if surface quality is not a top priority.

Ultimately, choosing a vacuum furnace is a decision to prioritize material integrity and process purity from the very start.

Summary Table:

| Aspect | Key Benefit |

|---|---|

| Pollution Reduction | Prevents oxidation and eliminates need for secondary cleaning processes like acid pickling, reducing hazardous waste |

| Material Performance | Improves ductility and toughness by maintaining surface purity and enhancing crystal structure |

| Process Efficiency | Offers precise temperature control and uniformity, minimizing part failures and material waste |

| Cost Considerations | Higher initial investment but reduces long-term waste and secondary processing costs |

Ready to enhance your lab's efficiency with pollution-free annealing? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our vacuum annealing furnaces can deliver superior material purity and reduce environmental impact for your specific applications!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment