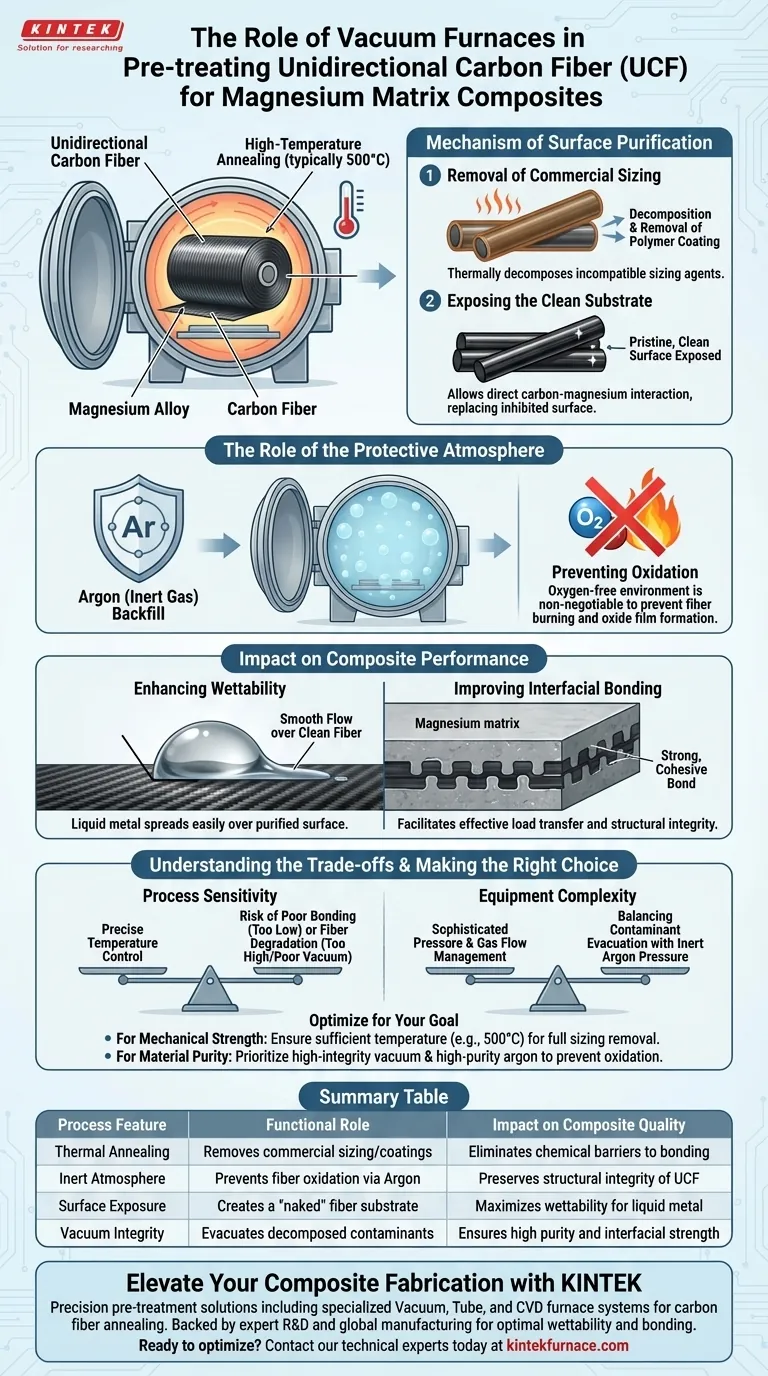

In the pre-treatment of Unidirectional Carbon Fiber (UCF) for magnesium matrix composites, the vacuum furnace serves a critical purification function. Specifically, it performs high-temperature annealing (typically at 500°C) to strip away commercial sizing agents from the fiber surface while maintaining a protective environment.

The core objective of this process is to replace a chemically inhibited surface with a pristine one. By removing commercial coatings in an oxygen-free atmosphere, the vacuum furnace significantly improves the wettability of the fiber, ensuring the metal matrix can form a strong, cohesive bond during composite fabrication.

The Mechanism of Surface Purification

Removal of Commercial Sizing

Raw carbon fibers typically arrive with a layer of commercial "sizing" (a polymer coating) applied by the manufacturer to protect the fibers during handling.

This sizing is often incompatible with metal matrices like AZ31 (a magnesium alloy). The vacuum furnace uses high temperatures to thermally decompose and remove this coating.

Exposing the Clean Substrate

Once the sizing is removed, the "naked" carbon fiber surface is exposed.

This clean surface is essential because it allows for direct interaction between the carbon and the magnesium matrix, rather than having an intermediate layer of burned or incompatible polymer interfering with the connection.

The Role of the Protective Atmosphere

The Necessity of Argon

While heat is required to burn off the sizing, heat in the presence of oxygen would destroy the carbon fiber itself.

The vacuum furnace solves this by evacuating air and backfilling the chamber with an inert gas, such as argon.

Preventing Oxidation

This oxygen-free environment is non-negotiable.

If oxygen were present at 500°C, the carbon fibers would oxidize (burn), and the magnesium matrix (if present in later steps) would form oxide films that hinder heat transfer and bonding. The vacuum furnace creates a "safe zone" for thermal treatment.

Impact on Composite Performance

Enhancing Wettability

"Wettability" refers to how easily a liquid metal spreads over a solid surface.

By removing the sizing and preventing surface oxidation, the vacuum furnace treatment ensures the magnesium alloy can flow smoothly over and around the individual carbon fibers.

Improving Interfacial Bonding

The ultimate goal of this pre-treatment is structural integrity.

A clean, high-energy surface facilitates strong adhesion between the fiber and the metal. This results in a composite where the load is effectively transferred from the matrix to the strong fibers, maximizing mechanical performance.

Understanding the Trade-offs

Process Sensitivity

While effective, this process relies heavily on precise temperature control.

If the temperature is too low, the sizing agents may not be fully removed, leading to poor bonding. If the temperature is too high or the vacuum integrity is compromised, the fiber surface may degrade, weakening the final composite.

Equipment Complexity

Unlike simple air ovens, vacuum furnaces require sophisticated management of pressure and gas flow.

The system must balance the evacuation of contaminants (decomposed sizing) with the maintenance of the inert argon pressure to prevent back-streaming of air.

Making the Right Choice for Your Goal

To optimize the pre-treatment of UCF for your specific magnesium composite application:

- If your primary focus is mechanical strength: Ensure the annealing temperature is sufficient (e.g., 500°C) to fully remove sizing, as residual polymers act as defects that weaken the interface.

- If your primary focus is material purity: Prioritize a high-integrity vacuum and high-purity argon source to prevent even micro-levels of oxidation on the fiber surface.

Success in magnesium matrix composites begins with a chemically clean fiber interface, achieved only through precise vacuum annealing.

Summary Table:

| Process Feature | Functional Role | Impact on Composite Quality |

|---|---|---|

| Thermal Annealing | Removes commercial sizing/coatings | Eliminates chemical barriers to bonding |

| Inert Atmosphere | Prevents fiber oxidation via Argon | Preserves structural integrity of UCF |

| Surface Exposure | Creates a "naked" fiber substrate | Maximizes wettability for liquid metal |

| Vacuum Integrity | Evacuates decomposed contaminants | Ensures high purity and interfacial strength |

Elevate Your Composite Fabrication with KINTEK

Precision pre-treatment is the foundation of high-performance magnesium matrix composites. KINTEK provides industry-leading thermal solutions, including specialized Vacuum, Tube, and CVD furnace systems engineered for the delicate requirements of carbon fiber annealing.

Backed by expert R&D and global manufacturing excellence, our systems offer the precise temperature control and atmospheric purity needed to ensure optimal fiber wettability and interfacial bonding. Whether you require a standard lab setup or a fully customized high-temperature furnace, KINTEK delivers the reliability your research demands.

Ready to optimize your material performance? Contact our technical experts today to discuss your unique project needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the working principle of a vacuum heat treatment furnace? Achieve Clean, High-Integrity Metal Parts

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- How are vacuum annealing furnaces used in solar cell manufacturing? Boost Efficiency with Precision Heat Treatment

- What control options are available for vacuum annealing furnaces? Explore PLC, Modes, and Precision Control

- What are the benefits of using vacuum furnaces for heat treating compared to traditional methods? Achieve Superior Quality and Control

- What is the primary function of the vacuum system in the vacuum distillation process for metal purification? Achieve High-Purity Metal Separation

- What are the key steps in vacuum brazing? Master the 5-Step Process for Strong, Clean Joints

- What is vacuum brazing? Achieve Superior Joint Integrity in High-Tech Applications