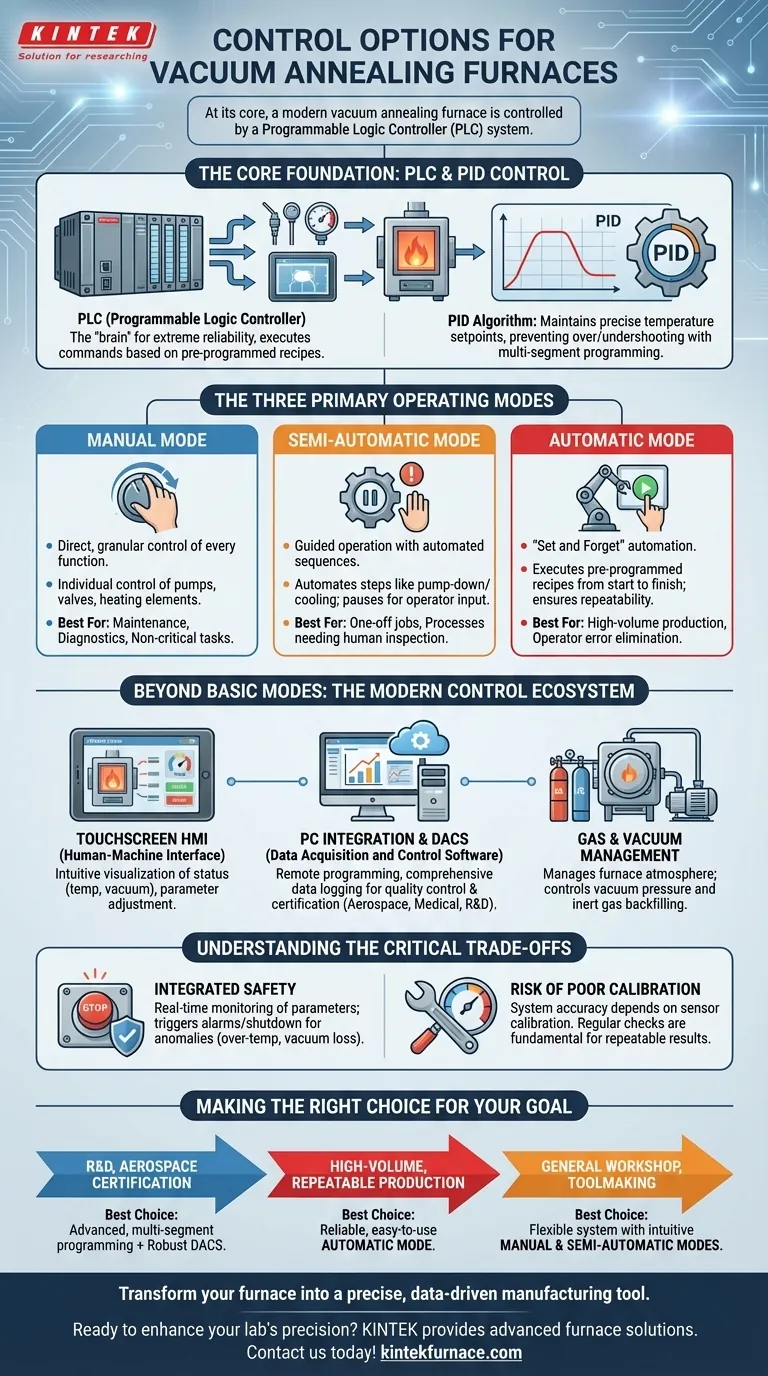

At its core, a modern vacuum annealing furnace is controlled by a Programmable Logic Controller (PLC) system. This industrial computer enables three primary operating modes—automatic, semi-automatic, and manual—which are typically managed through a touchscreen interface, providing a flexible solution for nearly any heat treatment requirement.

The choice of a control system is not just about a user interface; it's about defining the level of precision, repeatability, and data integrity your process requires. The real decision lies in matching the control system’s capabilities to the specific demands of your application, from simple manual tasks to fully automated, certifiable production runs.

The Foundation: PLC and PID Control

The entire operation hinges on a central controller that executes commands with high precision. This is where PLCs and PID algorithms come into play.

What is a PLC?

A Programmable Logic Controller (PLC) is the industrial-grade computer that acts as the brain of the furnace. It is designed for extreme reliability in harsh environments.

The PLC receives input from sensors (temperature, pressure) and sends output commands to actuators (heating elements, valves, pumps) based on a pre-programmed recipe.

The Role of PID for Temperature Precision

A Proportional-Integral-Derivative (PID) controller is a sophisticated algorithm running on the PLC. Its sole purpose is to maintain the furnace temperature at the desired setpoint with incredible accuracy.

It continuously calculates the error between the setpoint and the actual temperature, adjusting the heating power to prevent overshooting or undershooting. Advanced systems allow for multi-segment programming, enabling complex heat/cool cycles with different ramps and dwell times.

The Three Primary Operating Modes

The PLC-based system gives operators the flexibility to choose how they interact with the furnace, depending on the task at hand.

Manual Mode: Direct Operator Control

In manual mode, the operator has direct, granular control over every function. This includes individually turning on pumps, opening valves, or setting the power to heating elements.

This mode is essential for maintenance, system diagnostics, and simple, non-critical heating tasks that don't require a repeatable recipe.

Semi-Automatic Mode: Guided Operation

Semi-automatic mode provides a balance between manual flexibility and automated consistency. Certain sequences, like the initial pump-down or the cooling cycle, can be automated.

However, the process will pause at key decision points, requiring operator verification or input before proceeding. This is ideal for one-off jobs or processes that require human inspection at intermediate stages.

Automatic Mode: "Set and Forget" Automation

This is the workhorse mode for production environments. The operator selects a pre-programmed recipe, presses start, and the PLC executes the entire process from start to finish without intervention.

Automatic mode ensures maximum repeatability and eliminates operator error, making it critical for high-volume manufacturing where every part must undergo the exact same thermal cycle.

Beyond Basic Modes: The Modern Control Ecosystem

A control system is more than just its operating modes. The user interface, data management, and integration with other systems are what unlock its full potential.

Touchscreen HMI (Human-Machine Interface)

Modern furnaces use graphical touchscreen panels as the primary HMI. These interfaces provide a clear, real-time visualization of the furnace status, including temperature, vacuum level, and current process step. Adjusting parameters and building recipes becomes intuitive and straightforward.

PC Integration and Data Acquisition (DACS)

For applications in aerospace, medical, or advanced R&D, data is paramount. Many systems offer PC integration via Data Acquisition and Control Software (DACS).

This allows for remote programming and monitoring but, more importantly, provides comprehensive data logging of all process parameters. This creates an unalterable record for quality control, process validation, and certification.

Gas and Vacuum Management

The control system also manages the entire atmosphere within the furnace. This includes controlling the vacuum pumps to achieve and maintain the required pressure level and managing the gas management system for controlled backfilling with inert gases like nitrogen or argon.

Understanding the Critical Trade-offs

A powerful control system is an asset, but its effectiveness depends on a holistic understanding of its functions and limitations.

The Focus on Integrated Safety

A control system's most important job is ensuring safe operation. The PLC continuously monitors critical parameters in real-time.

It is programmed to trigger alarms or initiate an emergency shutdown in response to anomalies like over-temperature conditions, cooling water flow failure, or a sudden loss of vacuum.

The Risk of Poor Calibration

A sophisticated control system is only as accurate as its sensors. If thermocouples or pressure gauges are not calibrated regularly, the data on the screen will not reflect the true conditions inside the furnace.

Regular calibration is not an optional maintenance step; it is a fundamental requirement for achieving accurate and repeatable results. Without it, the precision of the entire system is compromised.

Making the Right Choice for Your Goal

Selecting the right control features depends entirely on your end goal.

- If your primary focus is R&D or aerospace certification: Prioritize systems with advanced, multi-segment programming and a robust Data Acquisition and Control Software (DACS) for complete process logging and validation.

- If your primary focus is high-volume, repeatable production: A system with a reliable and easy-to-use automatic mode is non-negotiable to ensure consistency and minimize operator-induced variations.

- If your primary focus is general workshop use or toolmaking: A flexible system with intuitive manual and semi-automatic modes provides the best balance for handling a wide variety of non-standard jobs.

Ultimately, understanding these control layers transforms your furnace from a simple oven into a precise, data-driven manufacturing tool.

Summary Table:

| Control Option | Key Features | Best For |

|---|---|---|

| Manual Mode | Direct operator control, granular adjustments | Maintenance, diagnostics, non-critical tasks |

| Semi-Automatic Mode | Guided operation with automated sequences | One-off jobs, processes needing human input |

| Automatic Mode | Full automation, pre-programmed recipes | High-volume production, repeatability |

| PLC with PID | Precise temperature control, multi-segment programming | Applications requiring high accuracy |

| DACS Integration | Data logging, remote monitoring, validation | Aerospace, medical, R&D certification |

Ready to enhance your lab's precision and efficiency? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental needs. Contact us today to discuss how our tailored vacuum annealing furnace controls can optimize your processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today