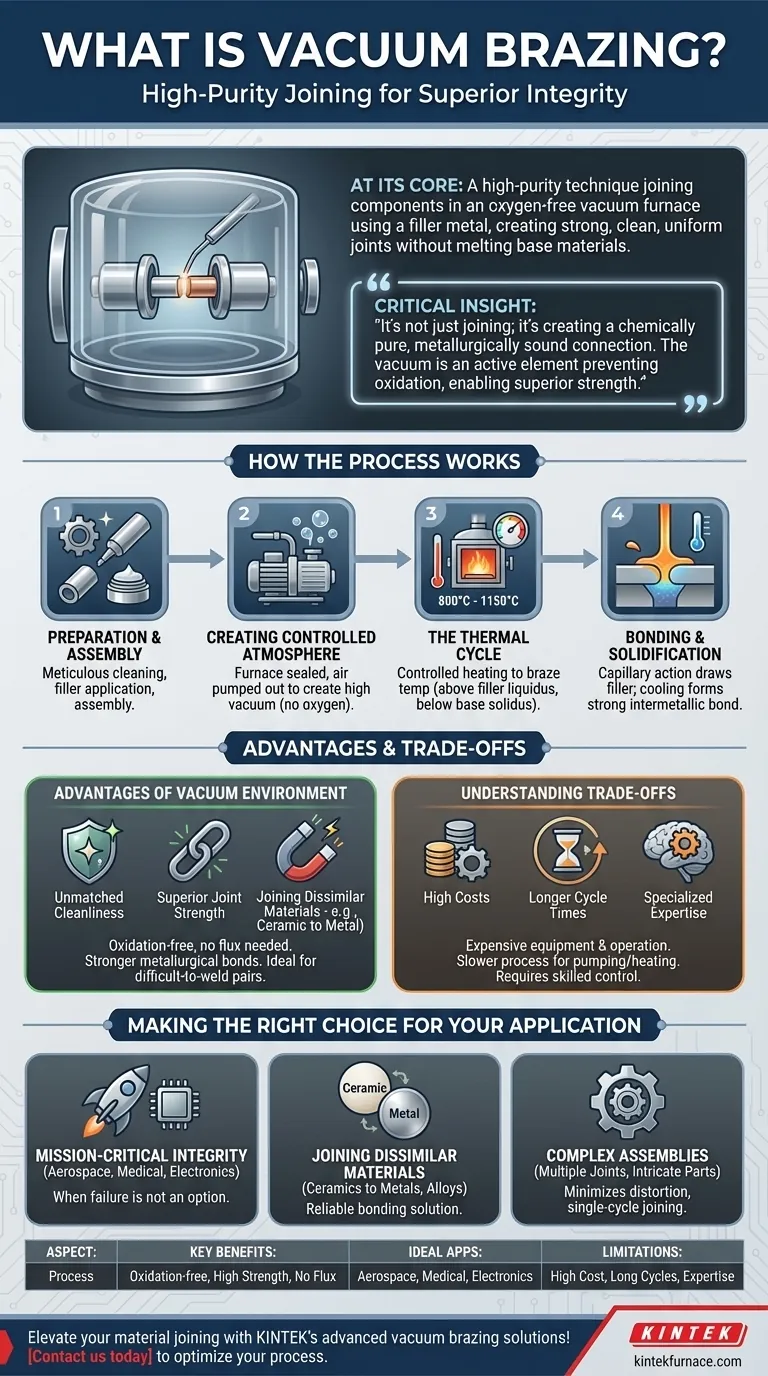

At its core, vacuum brazing is a high-purity material joining technique that uses a filler metal to bond components together inside a vacuum furnace. By heating the assembly in a controlled, oxygen-free environment, the filler metal melts and flows between the parts, creating a strong, clean, and uniform joint upon cooling without melting the base materials themselves.

The critical insight is that vacuum brazing isn't just about joining parts; it's about creating a chemically pure and metallurgically sound connection. The vacuum is not a passive environment but an active element that prevents oxidation and contamination, enabling joints of superior strength and integrity that are impossible with conventional methods.

How the Vacuum Brazing Process Works

To understand vacuum brazing, it’s best to view it as a precise, multi-stage thermal and chemical process. Each step is critical to achieving a perfect joint.

Step 1: Preparation and Assembly

Parts must be meticulously cleaned to remove any oils, oxides, or other surface contaminants. The brazing filler metal, often in the form of a paste, foil, or preform, is then applied to the joint area. The components are assembled in their final configuration, ready for the furnace.

Step 2: Creating the Controlled Atmosphere

The entire assembly is placed inside a vacuum furnace. Air and other gases are pumped out to create a high-vacuum environment. This removal of oxygen is the most crucial step for preventing oxidation, which can weaken the joint and compromise the material's properties. Sometimes, the chamber is backfilled with an inert gas like argon to create a protective atmosphere.

Step 3: The Thermal Cycle

The furnace heats the assembly in a highly controlled manner. The temperature is raised above the melting point of the filler metal (its liquidus temperature) but kept below the melting point of the base components (their solidus temperature).

The assembly is held at this brazing temperature, typically between 800°C and 1150°C, for a short duration. This allows the molten filler to flow completely into the joint.

Step 4: Bonding and Solidification

During the heating stage, the molten filler metal is drawn into the tight gaps between the components through a phenomenon called capillary action. Upon controlled cooling, the filler solidifies and forms a strong, permanent intermetallic bond with the parent materials.

The Advantages of a Vacuum Environment

The use of a vacuum furnace is what separates this process from other forms of brazing and provides its unique benefits.

Unmatched Cleanliness and Integrity

By removing oxygen, the vacuum prevents the formation of oxides on the joint surfaces. This eliminates the need for corrosive fluxes used in other brazing methods, which can become trapped in the joint and create a point of failure. The result is an exceptionally clean and bright finish.

Superior Joint Strength

Because there are no oxides or flux contaminants, the brazing filler metal can achieve a complete metallurgical bond with the parent materials. This leads to joints that are often as strong, or even stronger, than the materials being joined.

Joining Dissimilar and Advanced Materials

Vacuum brazing excels at joining materials that are difficult or impossible to weld, such as ceramics to metals or different types of high-performance alloys. The uniform, slow heating and cooling minimizes thermal stress, preventing cracks in materials with different expansion rates.

Understanding the Trade-offs

While powerful, vacuum brazing is not the solution for every application. Its benefits come with practical considerations.

High Equipment and Operating Costs

Vacuum furnaces are complex and expensive pieces of equipment. The cost of operation, including energy consumption and maintenance, is significantly higher than that of simple torch or induction brazing setups.

Longer Cycle Times

The process of pumping down to a vacuum, heating uniformly, and cooling slowly makes the overall cycle time much longer than other joining methods. This makes it less suitable for high-volume, low-cost production.

Requires Specialized Expertise

Properly operating a vacuum furnace and designing a successful brazing cycle requires a high level of technical skill and metallurgical knowledge. Process parameters must be precisely controlled to achieve repeatable, high-quality results.

Making the Right Choice for Your Application

Selecting vacuum brazing depends entirely on your project's specific requirements for performance, materials, and quality.

- If your primary focus is mission-critical integrity: Vacuum brazing is the ideal choice for applications in aerospace, medical implants, and high-performance electronics where joint failure is not an option.

- If your primary focus is joining dissimilar materials: This process offers a reliable solution for bonding items like ceramic insulators to steel components or joining reactive metals like titanium.

- If your primary focus is complex assemblies: The uniform heating of a furnace minimizes distortion and is perfect for joining intricate parts with multiple joints in a single cycle.

Ultimately, choosing vacuum brazing is a decision to prioritize metallurgical perfection and joint integrity above speed and cost.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Joining with filler metal in a vacuum furnace, heating above filler's melting point but below base materials' melting point. |

| Key Benefits | Oxidation-free joints, superior strength, ability to join dissimilar materials like ceramics to metals, no flux required. |

| Ideal Applications | Aerospace, medical implants, high-performance electronics, complex assemblies with multiple joints. |

| Limitations | High equipment costs, longer cycle times, requires specialized expertise for precise control. |

Elevate your material joining with KINTEK's advanced vacuum brazing solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like our Vacuum & Atmosphere Furnaces, designed for superior performance. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering clean, strong joints for critical applications in aerospace, medical, and electronics. Contact us today to discuss how we can optimize your brazing process and achieve unparalleled joint integrity!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control