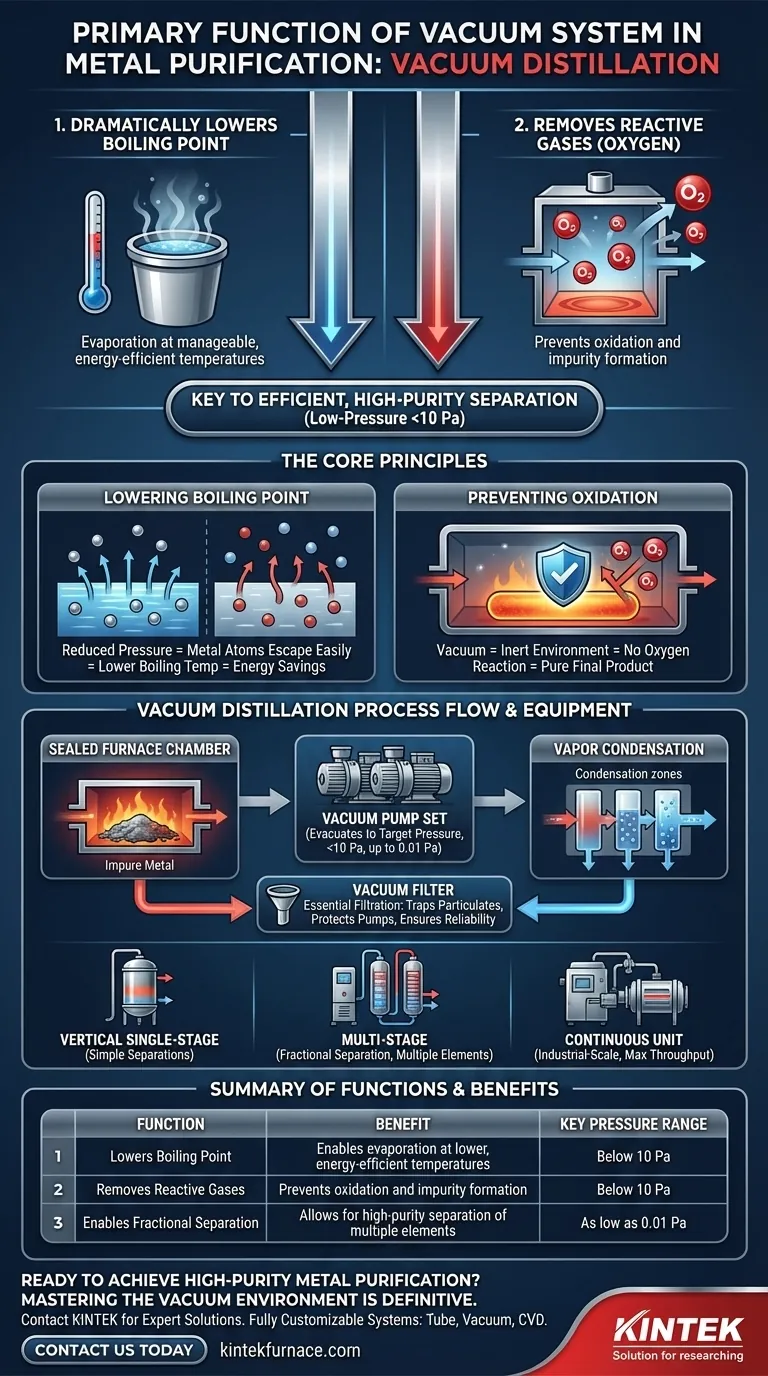

The primary function of the vacuum system in metal purification is twofold: it dramatically lowers the boiling point of the metal to allow for evaporation at manageable temperatures, and it removes reactive gases like oxygen to prevent the formation of impurities through oxidation. This low-pressure environment, often below 10 Pascals (Pa), is the key to an efficient and high-purity separation process.

The vacuum system doesn't just create an empty space; it fundamentally alters the physical and chemical conditions within the furnace, making it possible to separate metals from impurities with high precision and at lower, more energy-efficient temperatures.

The Core Principles: Why Vacuum is Essential

To understand vacuum distillation, you must grasp the two fundamental problems it solves: the energy cost of reaching a metal's boiling point and the chemical reactivity of hot metals. The vacuum system addresses both directly.

Lowering the Boiling Point

The boiling point of any liquid, including molten metal, is the temperature at which its vapor pressure equals the pressure of the surrounding environment. By using a vacuum system to remove most of the air, we drastically reduce the ambient pressure inside the furnace.

This low-pressure environment makes it significantly easier for metal atoms to escape the liquid surface and enter a gaseous state. As a result, the metal boils at a much lower temperature than it would at normal atmospheric pressure, accelerating the rate of evaporation and saving considerable energy.

Preventing High-Temperature Oxidation

Most metals are highly reactive with oxygen, especially at the elevated temperatures required for distillation. If performed in a standard atmosphere, the hot metal would quickly oxidize, forming new compounds that act as impurities and reduce the final yield.

The vacuum system purges the furnace of oxygen and other reactive gases. This creates an inert environment that protects the metal's integrity, ensuring the final condensed product is pure and free from unwanted oxide layers.

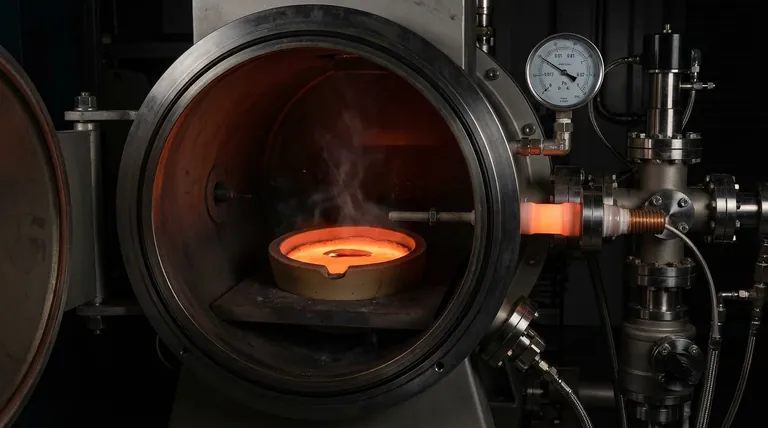

A Look Inside the Equipment

The principles of vacuum distillation are realized through a set of specialized components working in concert. While designs vary, the core elements remain consistent.

The Furnace and Pumping System

The process takes place within a sealed furnace chamber connected to a powerful vacuum pump set. These pumps are responsible for evacuating the chamber to the target pressure, sometimes as low as 0.01 Pa, creating the necessary conditions for distillation.

Variations in Furnace Design

Different purification goals require different equipment. A vertical single-stage furnace is used for simple separations. For more complex fractional separations, multi-stage furnaces use several condensation zones at different temperatures to separate multiple elements in a single batch.

For industrial-scale work, continuous vacuum distillation units allow for uninterrupted feeding and discharge, maximizing throughput.

Common Pitfalls and Operational Realities

Achieving and maintaining a deep vacuum in an industrial setting presents significant practical challenges that are critical to the success of the operation.

The Danger of Particulate Contamination

During evacuation, the high-velocity gas flow can carry fine dust and metal particles from the raw material. This is especially true when processing materials like hazardous waste containing fine magnesium.

These solid particles can be drawn into the delicate mechanical parts of the vacuum pumps, causing rapid wear, component failure, and costly downtime.

The Critical Role of Filtration

To prevent pump damage, a vacuum filter is always installed between the furnace and the pumps. This device contains filter media designed specifically to trap solid particulate matter before it can cause harm.

Proper filtration is not an optional accessory; it is essential for protecting the vacuum pumps and ensuring the long-term stability and reliability of the entire purification system.

Making the Right Choice for Your Goal

The specific application of vacuum distillation dictates the type of equipment and the operational parameters you should prioritize.

- If your primary focus is achieving the highest possible purity: A multi-stage condensation furnace capable of reaching extremely low pressures (deep vacuum) is the optimal choice for fractional separation.

- If your primary focus is industrial-scale throughput: A continuous vacuum distillation system with robust, automated feeding and a heavy-duty filtration system is required.

- If your primary focus is basic purification or process research: A simpler vertical or horizontal tube-type vacuum furnace offers a more flexible and cost-effective solution.

Ultimately, mastering the vacuum environment is the definitive factor in achieving successful, high-purity metal separation.

Summary Table:

| Function | Benefit | Key Pressure Range |

|---|---|---|

| Lowers Boiling Point | Enables evaporation at lower, energy-efficient temperatures | Below 10 Pa |

| Removes Reactive Gases | Prevents oxidation and impurity formation | Below 10 Pa |

| Enables Fractional Separation | Allows for high-purity separation of multiple elements | As low as 0.01 Pa |

Ready to Achieve High-Purity Metal Purification?

Mastering the vacuum environment is the definitive factor in successful metal separation. Whether your goal is research, achieving the highest purity, or industrial-scale throughput, the right equipment is critical.

KINTEK's expert R&D and manufacturing team can provide the solution you need. We offer a range of high-temperature vacuum furnaces, including Tube, Vacuum, and CVD systems, all fully customizable to meet your unique purification challenges.

Let us help you enhance your process efficiency and product purity.

Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What materials are used for the heating elements in a vacuum furnace? Choose the Right Element for Your High-Temp Needs

- What role do the exhaust branch pipes at the top of a vacuum chamber play? Optimize Your Pressure Control Today

- What is the function of vacuum systems and sealing connectors? Mastering Pure and Controlled Chemical Environments

- How does a high-vacuum pump system facilitate the synthesis of high-quality calcium-based perrhenates? Expert Synthesis

- What are the main technical requirements for vacuum pumps in vacuum sintering furnaces? Ensure Material Purity and Efficiency