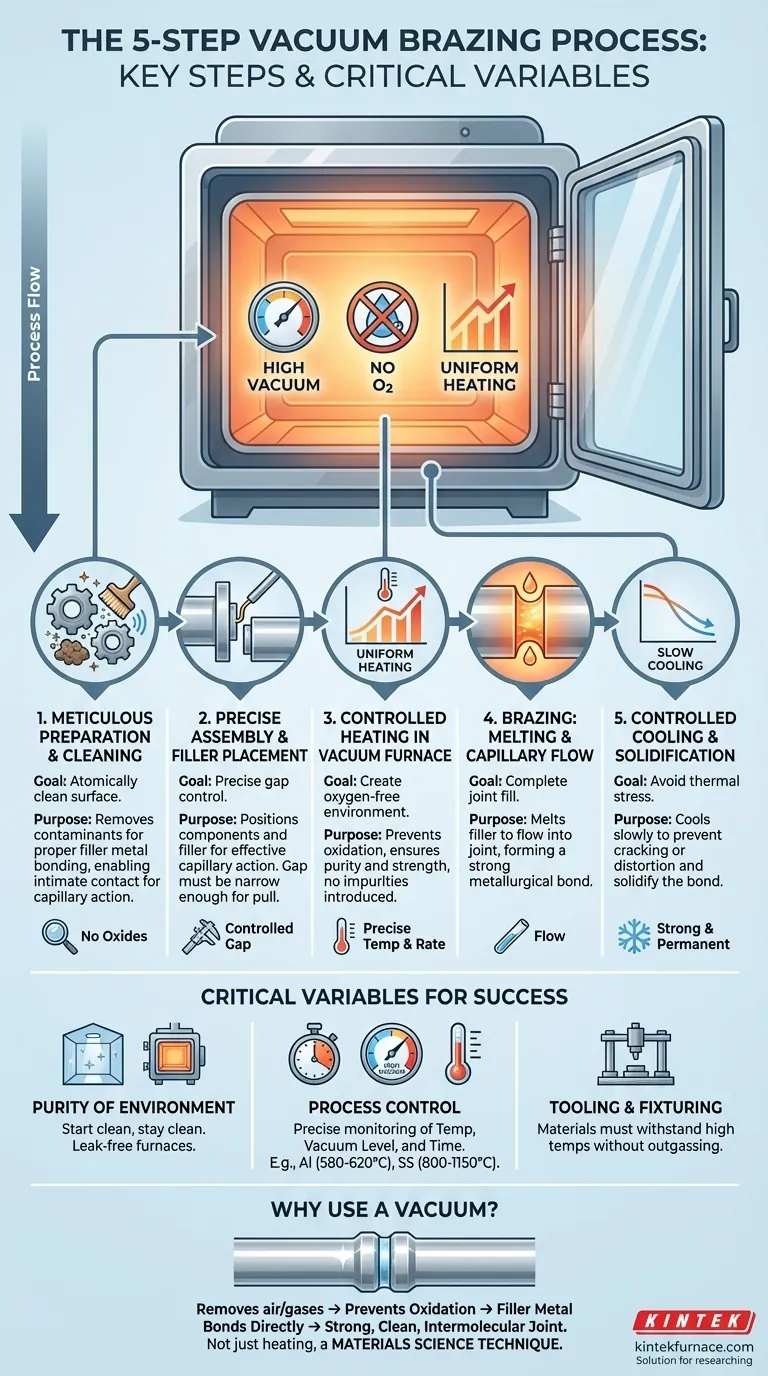

At its core, vacuum brazing is a five-step process: meticulously cleaning and preparing the components, assembling them with a filler metal at the joint, heating the assembly in a vacuum furnace, allowing the filler to melt and flow into the joint, and finally, cooling the part to solidify the bond. The vacuum environment is the critical element, as it prevents the formation of oxides that would otherwise inhibit a strong, clean joint.

Vacuum brazing is not just a heating process; it is a materials science technique that leverages a controlled, contamination-free environment to create a metallurgical bond between components without melting them. Success hinges less on the heat and more on the absolute cleanliness of the surfaces and the precision of the process controls.

The Foundational Principle: Why Use a Vacuum?

The primary purpose of using a vacuum furnace is to create an exceptionally clean environment. By removing air and other gases, you eliminate the risk of oxidation.

Preventing Oxidation

When metals are heated, they react rapidly with oxygen in the air, forming a layer of oxide on their surface. This oxide layer acts as a barrier, preventing the filler metal from properly "wetting" the surfaces of the parts and flowing into the joint.

A vacuum removes the oxygen, allowing the filler metal to bond directly with the pure parent material, which is essential for the strong, intermolecular bond that brazing creates.

Ensuring Purity and Strength

The vacuum environment ensures that no impurities are introduced into the joint during the heating process. This results in joints that are not only strong but also often as clean and bright as the parent materials, requiring little to no post-process cleaning.

A Step-by-Step Breakdown of the Process

Each step in the vacuum brazing cycle is a critical link in a chain. A failure in one step will compromise the integrity of the final joint.

Step 1: Meticulous Preparation and Cleaning

This is arguably the most critical step. All components must be thoroughly cleaned to remove oils, greases, dirt, and, most importantly, any existing surface oxides. An atomically clean surface is the goal.

Effective cleaning ensures that the molten filler metal can make intimate contact with the parent materials, which is a prerequisite for the capillary action that draws it into the joint.

Step 2: Precise Assembly and Filler Placement

The components are assembled into their final configuration. The filler metal, often in the form of a wire, paste, or pre-formed shim, is placed at the entrance to the joint.

The gap between the components must be precisely controlled. It must be wide enough to allow the filler to flow but narrow enough for capillary action—the force that pulls the liquid metal into the gap—to be effective.

Step 3: Controlled Heating in the Furnace

The assembled parts are loaded into the vacuum furnace. The furnace is sealed, and a high vacuum is pulled.

The parts are then heated according to a carefully planned thermal profile. The heating rate is controlled to ensure all parts of the assembly reach the target temperature uniformly, preventing thermal stress.

Step 4: Brazing—Melting and Capillary Flow

The assembly is heated to the specified brazing temperature. This temperature is above the liquidus temperature (the point at which it becomes fully liquid) of the filler metal but below the solidus temperature (the point at which it starts to melt) of the parent materials.

The assembly is held at this temperature for a specific duration, allowing the filler metal to melt completely and flow via capillary action, filling the entire joint.

Step 5: Controlled Cooling and Solidification

After the brazing is complete, the assembly is cooled in a controlled manner within the furnace. Slow cooling is crucial to prevent the introduction of thermal stresses, which could crack the joint or distort the part.

Once cooled, the filler metal solidifies, creating a strong, permanent, and often hermetic metallurgical bond between the components.

Understanding the Critical Variables for Success

Achieving a perfect braze requires more than just following the steps; it requires mastering the variables that influence the outcome.

The Purity of Your Environment

Success starts before the parts ever enter the furnace. Clean assembly rooms and high-quality, leak-free vacuum furnaces are non-negotiable. Any contamination introduced at this stage can lead to joint failure.

The Importance of Process Control

The key process variables—temperature, vacuum level, and time—must be precisely monitored and controlled. For example, the brazing temperature for aluminum alloys is typically 580°C to 620°C, while other materials like stainless steel or superalloys may require temperatures from 800°C to 1150°C.

The Role of Tooling and Fixturing

The tools and fixtures used to hold the components inside the furnace must be made of materials that can withstand high temperatures without deforming or outgassing (releasing trapped gases), which would compromise the vacuum.

How to Apply This to Your Project

Your specific goals will determine which aspects of the process demand the most attention.

- If your primary focus is maximum joint strength: Prioritize meticulous surface cleaning and precise temperature control to ensure a complete, void-free fill.

- If your primary focus is joining complex geometries: Concentrate on joint design and filler metal placement to optimize the path for capillary action.

- If your primary focus is joining dissimilar materials: Pay close attention to the thermal expansion rates of the materials and design a cooling cycle that minimizes residual stress.

Ultimately, successful vacuum brazing is a discipline of precision, where a controlled environment enables the creation of joints that are impossible to achieve through other methods.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Meticulous Preparation and Cleaning | Remove contaminants for proper filler metal bonding |

| 2 | Precise Assembly and Filler Placement | Position components and filler for capillary action |

| 3 | Controlled Heating in Vacuum Furnace | Heat uniformly in oxygen-free environment to prevent oxidation |

| 4 | Brazing—Melting and Capillary Flow | Melt filler to flow into joint, forming a metallurgical bond |

| 5 | Controlled Cooling and Solidification | Cool slowly to avoid stress and solidify the bond |

Ready to achieve flawless vacuum brazing results? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental needs for stronger, cleaner joints. Contact us today to discuss how our expertise can enhance your project!

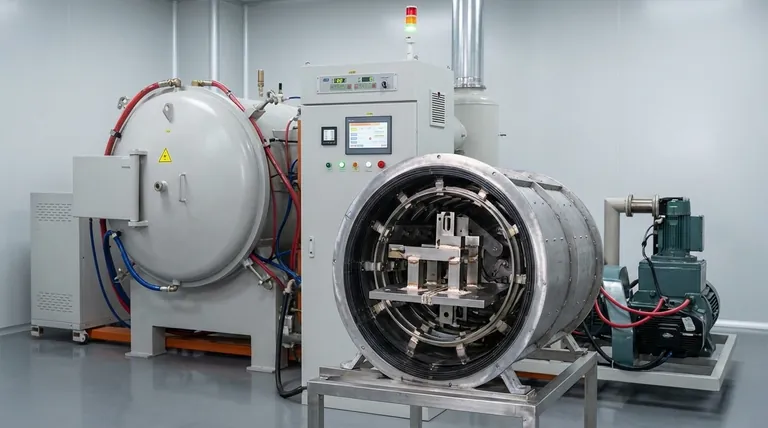

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness