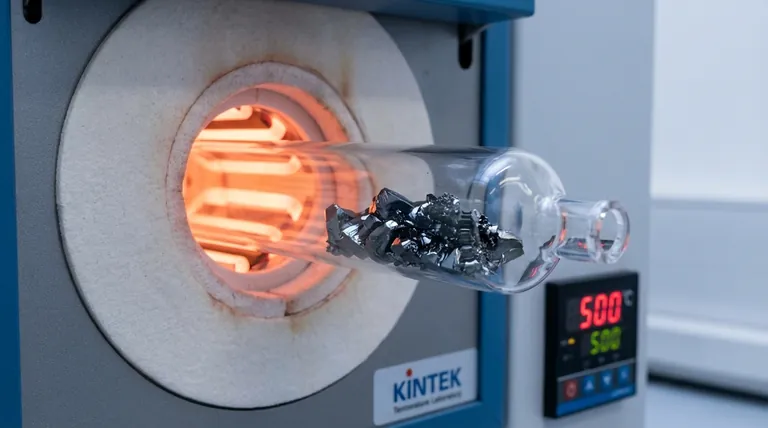

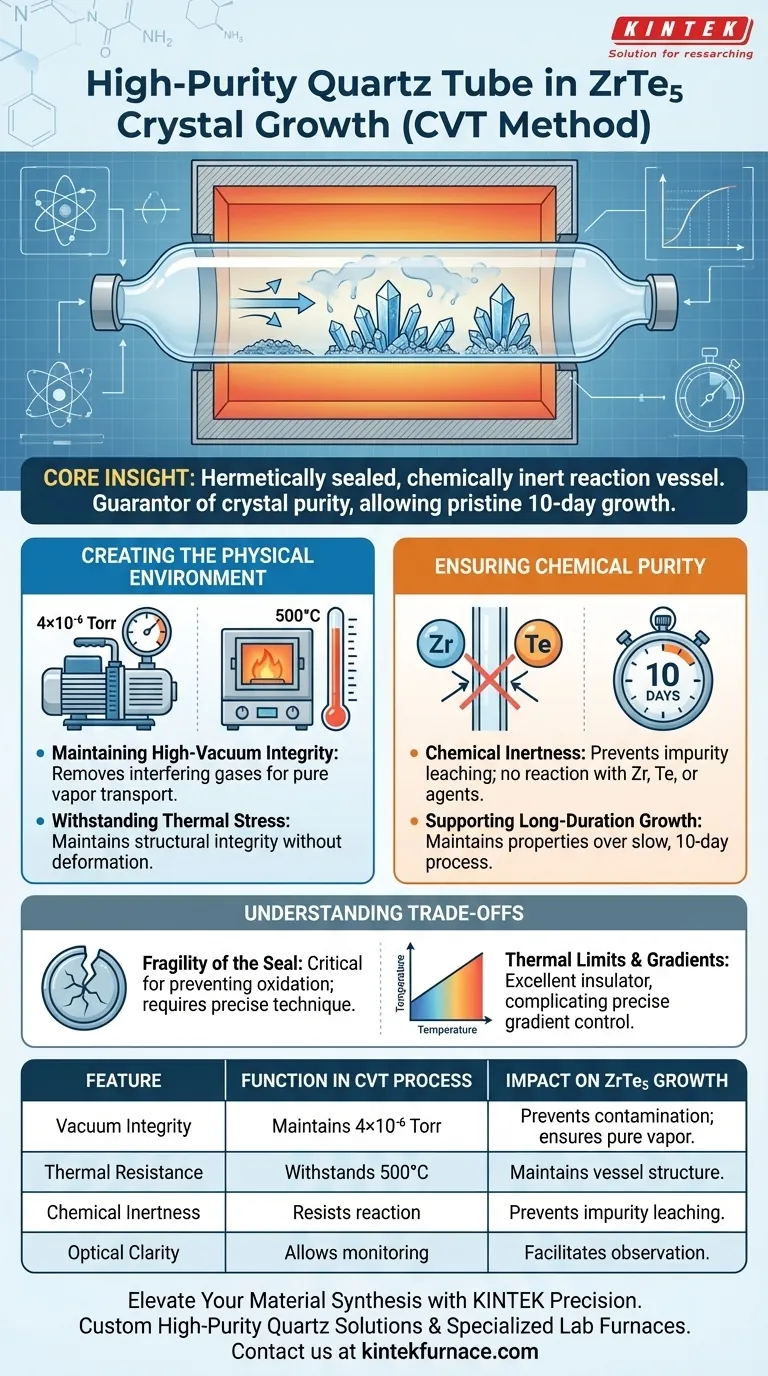

The high-purity quartz tube functions as a hermetically sealed, chemically inert reaction vessel critical for the Chemical Vapor Transport (CVT) process. Its primary role is to maintain a high-vacuum environment of approximately 4×10^-6 Torr while withstanding sustained temperatures of around 500°C, ensuring the isolation necessary for growing Zirconium Pentatelluride (ZrTe5) single crystals.

Core Insight: The quartz tube is the guarantor of crystal purity. By isolating the reaction from the external atmosphere and refusing to interact chemically with the reactants, it allows for a pristine, 10-day growth cycle that yields crystals with a distinct metallic luster.

Creating the Necessary Physical Environment

To understand the tube's function, you must first understand the hostile conditions required for CVT. The tube acts as the primary barrier between the delicate crystal growth and the outside world.

Maintaining High-Vacuum Integrity

The growth of ZrTe5 requires a contaminant-free environment. The quartz tube is evacuated to a vacuum of roughly 4×10^-6 Torr before being sealed.

This vacuum removes gases that could interfere with the vapor transport process. It ensures that the only vapors present are the specific raw materials and transport agents intended for the reaction.

Withstanding Thermal Stress

The CVT method operates at significant temperatures, specifically around 500°C for this application.

The high-purity quartz must withstand this heat without softening or deforming. It maintains its structural integrity throughout the heating phase, ensuring the volume and pressure within the vessel remain constant.

Ensuring Chemical Purity

The deep need in crystal growth is preventing unintended side reactions. The material choice of the vessel is as important as the reactants themselves.

Chemical Inertness

High-purity quartz is selected specifically for its chemical stability.

It does not react with the Zirconium, Tellurium, or the transport agents used in the process. This prevents impurities from leaching into the growing crystal lattice, which is essential for achieving the high purity required for research-grade samples.

Supporting Long-Duration Growth

The growth of ZrTe5 is not instantaneous; it is a slow process spanning approximately 10 days.

The tube must maintain its inert properties and vacuum seal for this entire duration. Any degradation in the tube wall over this period would compromise the final millimeter-scale crystals.

Understanding the Trade-offs

While high-purity quartz is the standard for this application, it imposes specific limitations that you must manage.

The Fragility of the Seal

The reliability of the entire process hinges on the initial vacuum seal.

Because quartz is brittle, creating a perfect seal that holds 4×10^-6 Torr at 500°C requires precise technique. A microscopic failure in the seal leads to oxidation and immediate failure of the growth run.

Thermal Limits and Gradients

Quartz is an excellent insulator, which is generally beneficial, but it can complicate the management of temperature gradients.

In CVT, a precise temperature difference drives transport. The tube's wall thickness must be uniform to ensure the thermal field inside matches the gradient applied by the furnace, otherwise, nucleation may occur unpredictably.

Making the Right Choice for Your Goal

The use of high-purity quartz is dictated by the specific requirements of your end product.

- If your primary focus is optical and structural quality: Prioritize the cleanliness of the quartz and the quality of the vacuum seal to ensure the distinct metallic luster and millimeter-scale dimensions.

- If your primary focus is experimental throughput: Ensure your sealing protocols are standardized, as the 10-day duration means any failure in the tube's integrity results in significant lost time.

Success in growing ZrTe5 lies in treating the quartz tube not just as a container, but as a critical, active component of the synthesis environment.

Summary Table:

| Feature | Function in CVT Process | Impact on ZrTe5 Growth |

|---|---|---|

| Vacuum Integrity | Maintains $4 \times 10^{-6}$ Torr | Prevents contamination; ensures pure vapor transport |

| Thermal Resistance | Withstands constant 500°C | Maintains vessel structure over 10-day cycles |

| Chemical Inertness | Resists reaction with Zr, Te, or agents | Prevents impurity leaching into the crystal lattice |

| Optical Clarity | Allows monitoring of nucleation | Facilitates growth observation and gradient control |

Elevate Your Material Synthesis with KINTEK Precision

Precision in ZrTe5 single crystal growth demands more than just raw materials—it requires the perfect environment. Backed by expert R&D and manufacturing, KINTEK provides high-purity quartz solutions and specialized lab high-temp furnaces, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard dimensions or a custom setup tailored for specific temperature gradients, our equipment is designed to ensure the chemical purity and structural integrity your research-grade samples require.

Ready to optimize your CVT or high-temperature lab processes? Contact us today to discuss your unique needs and discover how KINTEK can enhance your lab's efficiency and success.

Visual Guide

References

- Yueying Hou, Yan‐Feng Chen. Probing Anisotropic Quasiparticle Dynamics and Topological Phase Transitions in Quasi‐1D Topological Insulator ZrTe<sub>5</sub>. DOI: 10.1002/advs.202504798

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What physical conditions do high-temperature tube furnaces provide for flue gas kinetics? Precision Thermal Simulation

- What role does a high-temperature tube furnace play in nanoporous carbon synthesis? Essential Activation Stage Insights

- Why is a tube furnace with precise temperature control necessary for Fe7S8@CT-NS composites? Master Advanced Synthesis

- What is the function of a high-temperature tube furnace in Ti3AlC2 synthesis? Achieve Pure MAX Phase Precursor Powders

- How does a tube furnace facilitate gas-phase hydrogenation for Zircaloy-4? Achieve Precise Hydride Precipitation

- How do tube furnaces function and where are they used? Discover Precision Heating Solutions

- What role does a tube resistance furnace play during the oxidative roasting phase of ore pellets? Master Heat Precision

- What is the purpose of using a tube furnace for a second calcination at 750°C? Mastering Biochar Activation