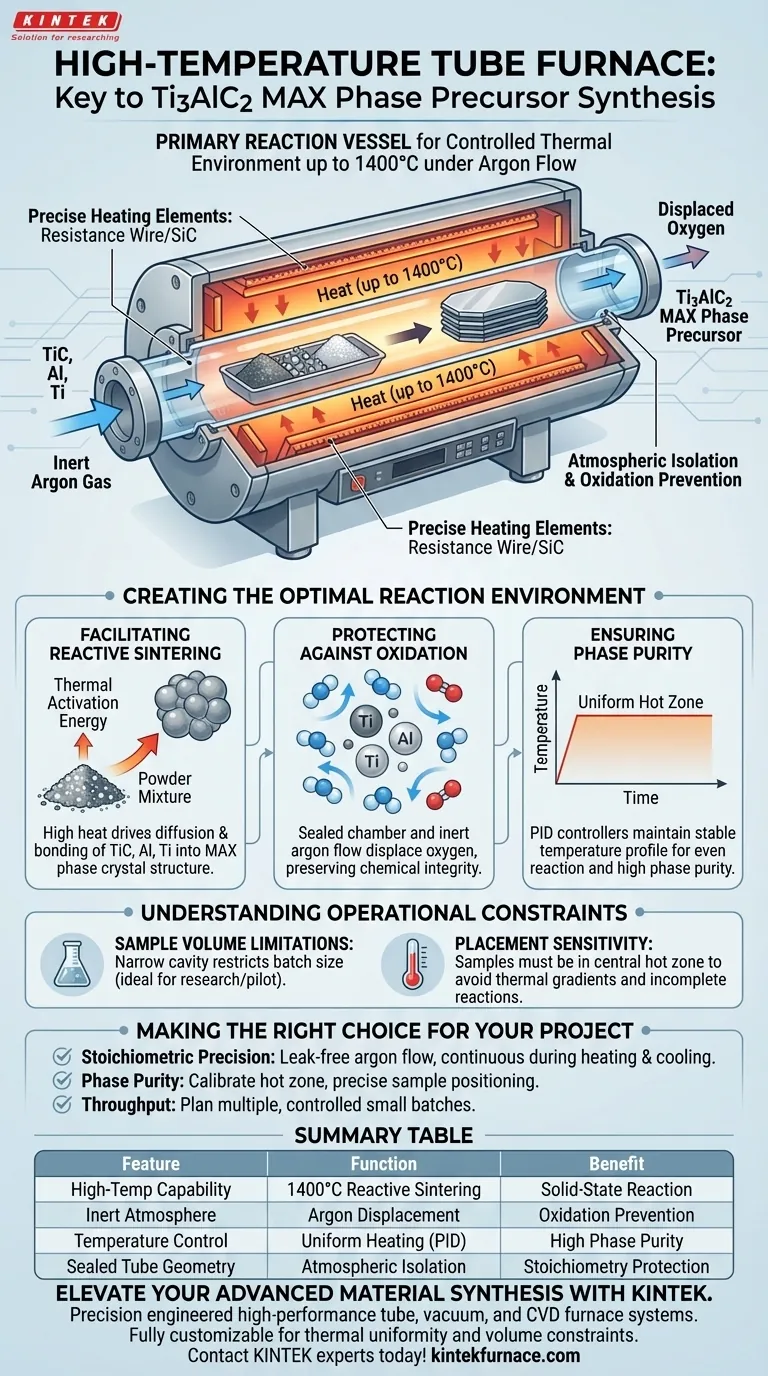

A high-temperature tube furnace functions as the primary reaction vessel for synthesizing Ti3AlC2 MAX phase precursor powders. It creates a controlled thermal environment capable of reaching 1400°C under a continuous flow of inert argon gas. This specific setup is required to facilitate the reactive sintering of titanium carbide (TiC), aluminum (Al), and titanium (Ti) elemental powders while strictly preventing oxidation.

The core value of the tube furnace is its ability to couple extreme heat with atmospheric isolation. It ensures the stoichiometric accuracy of the final precursor by enabling a complete solid-state reaction without the chemical contamination inherent in open-air thermal processing.

Creating the Optimal Reaction Environment

Facilitating Reactive Sintering

The synthesis of Ti3AlC2 is a solid-state reaction that requires significant thermal activation energy.

The tube furnace generates the necessary heat—specifically up to 1400°C—to drive the reactive sintering process. This high temperature forces the distinct TiC, Al, and Ti powders to diffuse and bond, transforming the raw mixture into the desired MAX phase crystal structure.

Protecting Against Oxidation

Titanium and aluminum powders are highly reactive to oxygen, especially at elevated temperatures.

The tube furnace utilizes a sealed cylindrical chamber that allows for the introduction of an inert gas, typically argon. By displacing oxygen with argon, the furnace prevents the raw materials from oxidizing during the heating cycle, ensuring the chemical integrity of the final product.

Ensuring Phase Purity

In MAX phase synthesis, temperature uniformity is critical to prevent the formation of unwanted secondary phases.

The furnace employs precise heating elements (such as resistance wire or SiC) and PID controllers to maintain a stable temperature profile across the sample. This uniformity ensures that the entire batch of powder reacts evenly, resulting in high phase purity and complete structural formation.

Understanding Operational Constraints

Sample Volume Limitations

While excellent for precision, tube furnaces generally utilize a narrow cylindrical cavity.

This geometry restricts the volume of sample material that can be processed in a single run. Consequently, this equipment is ideal for research and pilot-scale synthesis but may present a bottleneck for high-volume industrial production.

Placement Sensitivity

Although the central "hot zone" of the furnace offers high uniformity, temperature gradients can exist near the ends of the tube.

Samples must be positioned carefully within the precise center of the heating zone. Improper placement can lead to incomplete reactions or gradients in the final material properties.

Making the Right Choice for Your Project

To ensure successful Ti3AlC2 synthesis, align your equipment usage with your specific constraints:

- If your primary focus is stoichiometric precision: Ensure your gas lines are leak-free and maintain a continuous argon flow throughout both the heating and cooling phases to prevent re-oxidation.

- If your primary focus is phase purity: Calibrate the furnace to confirm the central hot zone's length and position your sample strictly within these limits to avoid thermal gradients.

- If your primary focus is throughput: Acknowledge the batch-size limitations of the tube geometry and plan for multiple, strictly controlled runs rather than overfilling a single boat.

Success in synthesizing MAX phase precursors relies not just on reaching 1400°C, but on maintaining absolute atmospheric control during the process.

Summary Table:

| Feature | Function in Ti3AlC2 Synthesis | Benefit |

|---|---|---|

| High-Temp Capability | Reaches up to 1400°C | Facilitates solid-state reactive sintering |

| Inert Atmosphere | Argon gas flow displacement | Prevents oxidation of Ti and Al powders |

| Temperature Control | PID-controlled uniform heating | Ensures high phase purity and structural integrity |

| Sealed Tube Geometry | Atmospheric isolation | Protects chemical stoichiometry and prevents contamination |

Elevate Your Advanced Material Synthesis with KINTEK

Precision is non-negotiable when synthesizing Ti3AlC2 MAX phases. KINTEK provides high-performance tube, vacuum, and CVD furnace systems specifically engineered to deliver the 1400°C stability and inert atmosphere control your research demands. Backed by expert R&D and manufacturing, our systems are fully customizable to overcome sample volume constraints and ensure absolute thermal uniformity.

Ready to optimize your lab's high-temperature processing? Contact KINTEK experts today to find the perfect solution for your unique needs!

Visual Guide

References

- Srinivasa Kartik Nemani, Babak Anasori. Ti <sub>3</sub> C <sub>2</sub> T <i> <sub>x</sub> </i> MXene‐Zirconium Diboride Based Ultra‐High Temperature Ceramics. DOI: 10.1002/advs.202500487

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of tube furnaces for certain applications? Unlock Precise Atmosphere and Temperature Control

- What is the significance of the calcination process using a high-temperature tube furnace? Enhance Bi2S3/BiOBr@In2S3 Performance

- What control options are available for tube furnaces? Scale from Simple Heating to Complex Automation

- Why is a tube furnace equipped with a nitrogen environment necessary for biochar? Achieve Precise Pyrolysis Control

- How is the application scope of vertical fluidized bed tube furnaces expected to evolve? Discover Future Innovations in Precision Heating

- In what settings are both tube and box furnaces commonly used? Optimize Your Thermal Processes with the Right Choice

- What is the primary function of a single-temperature zone tube furnace in MoS2 CVD? Master Your Synthesis Process

- What temperature should the furnace be at when loading or unloading samples? Stay Safe and Prevent Damage