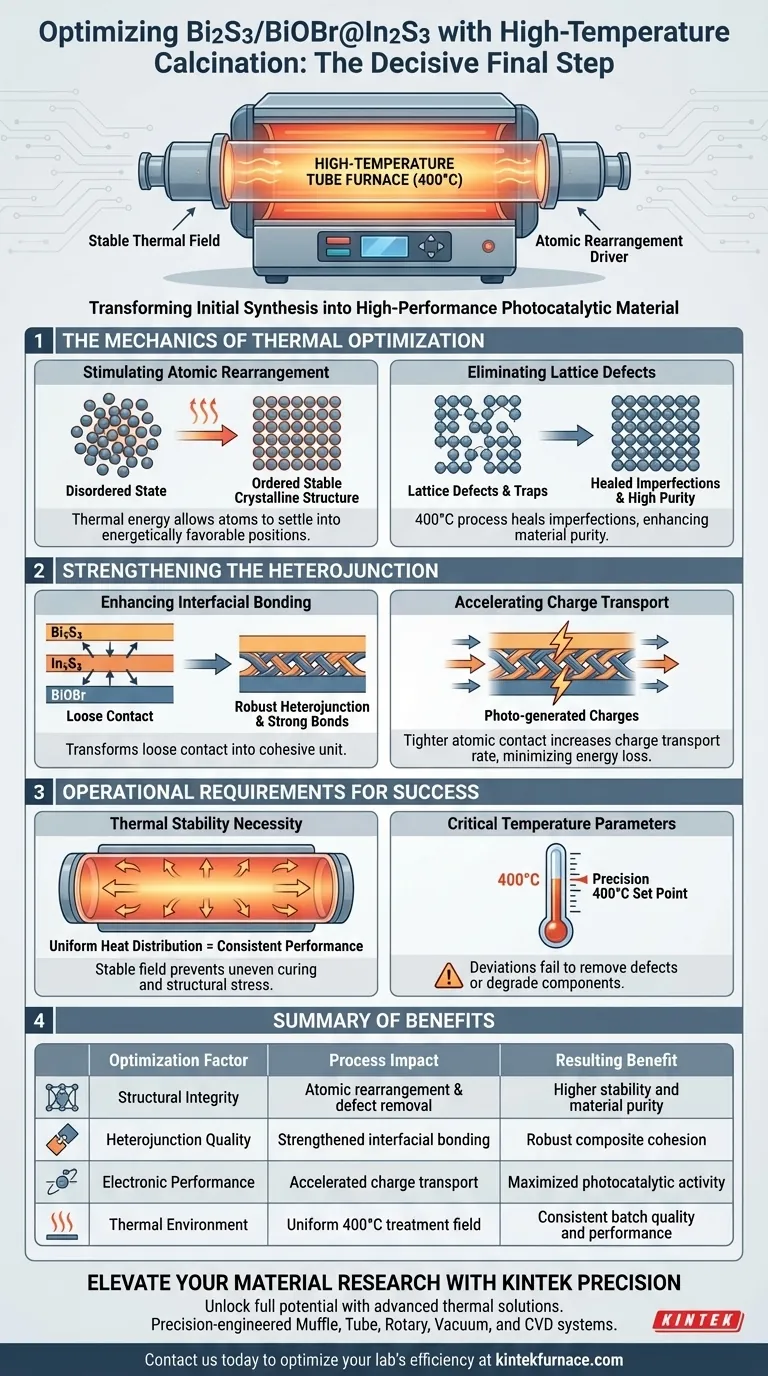

The calcination process using a high-temperature tube furnace is the decisive final step in optimizing the structural integrity of Bi2S3/BiOBr@In2S3. By maintaining a stable thermal field, typically at 400°C, this treatment drives the atomic rearrangement necessary to refine the composite material after initial synthesis.

Calcination provides the thermal energy required to eliminate lattice defects and solidify the bonds between material components. This structural perfection is the primary driver for efficient charge transport and maximized photocatalytic performance.

The Mechanics of Thermal Optimization

Stimulating Atomic Rearrangement

The synthesis of complex composites often leaves atoms in a disordered state. High-temperature treatment uses thermal energy to stimulate the movement of these atoms within the lattice structure.

This energy allows atoms to settle into more energetically favorable positions. The result is a more ordered, stable crystalline structure.

Eliminating Lattice Defects

During the initial creation of Bi2S3/BiOBr@In2S3, imperfections known as lattice defects are inevitably introduced. These defects can act as traps that hinder material performance.

The 400°C calcination process effectively heals these imperfections. By removing these defects, the material achieves a higher degree of purity and structural continuity.

Strengthening the Heterojunction

Enhancing Interfacial Bonding

The core strength of a composite material lies in how well its different components interact. Calcination significantly enhances the interfacial bonding strength between Bi2S3, In2S3, and BiOBr.

This process transforms loose contact into a robust heterojunction. A strong heterojunction is essential for the material to function as a cohesive unit rather than separate parts.

Accelerating Charge Transport

The physical connection between components dictates how well energy moves through the material. Tighter atomic-level contact directly increases the transport rate of photo-generated charges.

When charges move freely across the interface, energy loss is minimized. This optimization is the critical factor that boosts the overall photocatalytic activity of the final product.

Understanding the Operational Requirements

The Necessity of Thermal Stability

The reference emphasizes the use of a high-temperature tube furnace because it provides a stable thermal treatment field. Inconsistent heating can lead to uneven curing or structural stress.

Uniform heat distribution ensures that the entire sample undergoes the same degree of atomic rearrangement. This leads to consistent performance across the entire batch of material.

Critical Temperature Parameters

The process is typically operated at a specific set point of 400°C. This temperature is carefully selected to provide enough energy for rearrangement without destroying the material.

Deviating significantly from this temperature could fail to remove defects or potentially degrade the components. Precision in the thermal environment is non-negotiable for success.

Making the Right Choice for Your Goal

To maximize the potential of your Bi2S3/BiOBr@In2S3 composite, you must view calcination as a tuning process, not just a drying step.

- If your primary focus is Structural Stability: Ensure the tube furnace maintains a consistent 400°C to eliminate lattice defects and prevent future degradation.

- If your primary focus is Photocatalytic Efficiency: Prioritize this step to maximize the heterojunction strength, which directly correlates to faster charge transport rates.

Ultimately, the rigorous application of stable heat is what transforms a mixture of chemicals into a high-performance functional material.

Summary Table:

| Optimization Factor | Process Impact | Resulting Benefit |

|---|---|---|

| Structural Integrity | Atomic rearrangement & defect removal | Higher stability and material purity |

| Heterojunction Quality | Strengthened interfacial bonding | Robust composite cohesion |

| Electronic Performance | Accelerated charge transport | Maximized photocatalytic activity |

| Thermal Environment | Uniform 400°C treatment field | Consistent batch quality and performance |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your photocatalytic composites with KINTEK's advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all precision-engineered to provide the stable thermal fields essential for high-performance calcination.

Whether you require a standard 400°C treatment or a fully customizable high-temperature furnace tailored to your unique research needs, our systems ensure the structural perfection your materials deserve. Contact us today to optimize your lab's efficiency and discover the KINTEK advantage in material science.

Visual Guide

References

- Namasivayam Dhenadhayalan. Architecting ternary heteronanocomposites Bi2S3/BiOCl@In2S3 and Bi2S3/BiOBr@In2S3 for photocatalytic detoxification of organoarsenic compound. DOI: 10.1038/s41545-025-00469-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does an industrial-grade tube furnace play in Fe-P-NC catalyst pyrolysis? Precision Heating for Fe-P-NC Synthesis

- How does the design of tube furnaces ensure uniform heating? Master Precision with Multi-Zone Control

- What materials are recommended for constructing a tube furnace for high temperatures? Essential Guide for Labs

- What is the primary function of a high-temperature tube furnace for Ce-MOF to CeO2 conversion? Guide to Precision Nano-Engineering

- What are the specific functions of a vertical alumina tube reactor? Key Roles in Gasification Kinetics Research

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- Why is a High-Temperature Vacuum Tube Furnace required for the long-term homogenization of alloy ingots?

- Why is high-precision temperature control in a tube furnace critical for rhenium catalysts? Ensure Optimal Alumina Calcination