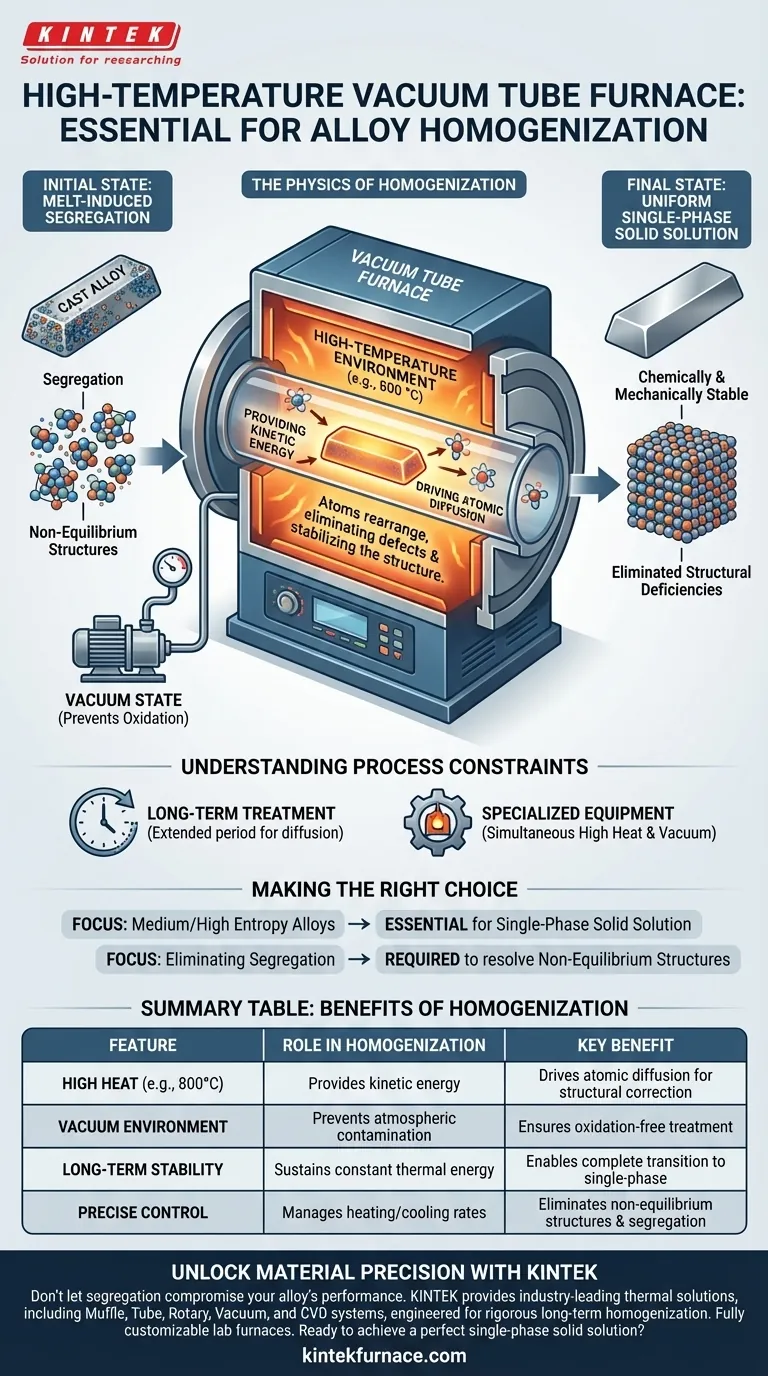

A High-Temperature Vacuum Tube Furnace is essential because it provides the strictly controlled environment necessary to reorganize an alloy's atomic structure after melting. It delivers the precise thermal energy required to drive atomic diffusion while maintaining a vacuum to ensure the process occurs without contamination.

By maintaining a stable high-temperature environment under vacuum, this equipment transforms a segregated, non-equilibrium casting into a uniform, single-phase solid solution.

Eliminating Structural Deficiencies

Addressing Melt-Induced Segregation

When alloy ingots are initially prepared via melting, they rarely cool into a perfect, uniform state. The solidification process generates segregation and non-equilibrium structures.

The Necessity of Correction

These structural inconsistencies result in a material that is chemically and mechanically unstable. To create a usable high-performance alloy, these initial defects must be eliminated through post-preparation treatment.

The Physics of Homogenization

Providing Kinetic Energy

Correcting the structure requires atoms to physically move and rearrange themselves within the solid material. The furnace creates a stable high-temperature environment, such as 800 °C.

Driving Atomic Diffusion

This intense heat provides the atoms with sufficient kinetic energy to diffuse. Without this added energy, the atoms would remain locked in their segregated positions.

Stabilizing the Solid Solution

As atoms diffuse, the chemical composition becomes uniform throughout the ingot. This thermal treatment is critical for stabilizing the single-phase solid solution structure, particularly for medium and high entropy alloys.

Understanding the Process Constraints

The Commitment to Long-Term Treatment

This method is not an instantaneous fix; it is a "long-term" homogenization process. It requires maintaining high temperatures and a vacuum state over an extended period to allow sufficient diffusion.

Equipment Dependency

You cannot achieve this result with standard heating methods. The requirement for simultaneous high heat and a vacuum necessitates specialized tube furnace architecture to prevent oxidation while energizing the atoms.

Making the Right Choice for Your Goal

To determine if this step is critical for your workflow, consider your specific material requirements:

- If your primary focus is Medium or High Entropy Alloys: You must use this process to stabilize the single-phase solid solution structure essential for these materials.

- If your primary focus is Eliminating Segregation: You require this specific thermal treatment to provide the kinetic energy needed to resolve non-equilibrium structures generated during melting.

Success in alloy preparation relies on recognizing that melting is only the beginning; true material stability is achieved through controlled heat and vacuum.

Summary Table:

| Feature | Role in Homogenization | Key Benefit |

|---|---|---|

| High Heat (e.g., 800°C) | Provides necessary kinetic energy | Drives atomic diffusion for structural correction |

| Vacuum Environment | Prevents atmospheric contamination | Ensures oxidation-free treatment of sensitive alloys |

| Long-term Stability | Sustains constant thermal energy | Enables complete transition to single-phase solid solution |

| Precise Control | Manages heating/cooling rates | Eliminates non-equilibrium structures and segregation |

Unlock Material Precision with KINTEK

Don't let segregation compromise your alloy's performance. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all engineered for rigorous long-term homogenization. Backed by expert R&D and precision manufacturing, our lab high-temperature furnaces are fully customizable to meet your specific material requirements.

Ready to achieve a perfect single-phase solid solution? Contact us today to discuss your unique research or production needs with our technical team.

Visual Guide

References

- Chao-hong Wang, Yue-Han Li. Liquid-State Interfacial Reactions of Lead-Free Solders with FeCoNiCr and FeCoNiMn Medium-Entropy Alloys at 250 °C. DOI: 10.3390/ma18102379

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does a tube furnace contribute to the accuracy of microplastic thermal decomposition? Ensure Pyrolysis Precision

- How do the heating elements in a tube furnace function? Uncover Key Insights for Precise Heating

- What core functions does a program-controlled tube furnace perform? Master BN@C Synthesis with Precision

- What role does a high-temperature tube furnace play in Pt/MoS2 synthesis? Master Atomic-Level Defect Engineering

- What is the primary function of a high-temperature tube furnace in h-BN preparation? Achieve Clean Surface Activation

- What are some standard models of tube furnaces and their specifications? Find the Perfect Fit for Your Lab

- Why are sealed quartz tubes required for TMD synthesis? Ensure Pure MoS2 & WS2 Growth

- What is the function of an industrial tube furnace during the secondary carbonization of biomass? Achieve Precision.