A tube furnace establishes the rigorous control required for accurate microplastic decomposition by isolating the sample in a stable, uniform thermal environment. By combining high-precision temperature regulation with strict atmospheric management, it ensures that the breakdown of molecular chains is driven solely by intended thermal parameters, rather than environmental fluctuations or oxygen contamination.

Success in microplastic pyrolysis relies on separating thermal effects from environmental interference. A tube furnace achieves this by maintaining an oxygen-free atmosphere and precise thermal gradients, ensuring that molecular chains break in a predictable, reproducible manner to yield high-quality bio-oil and syngas.

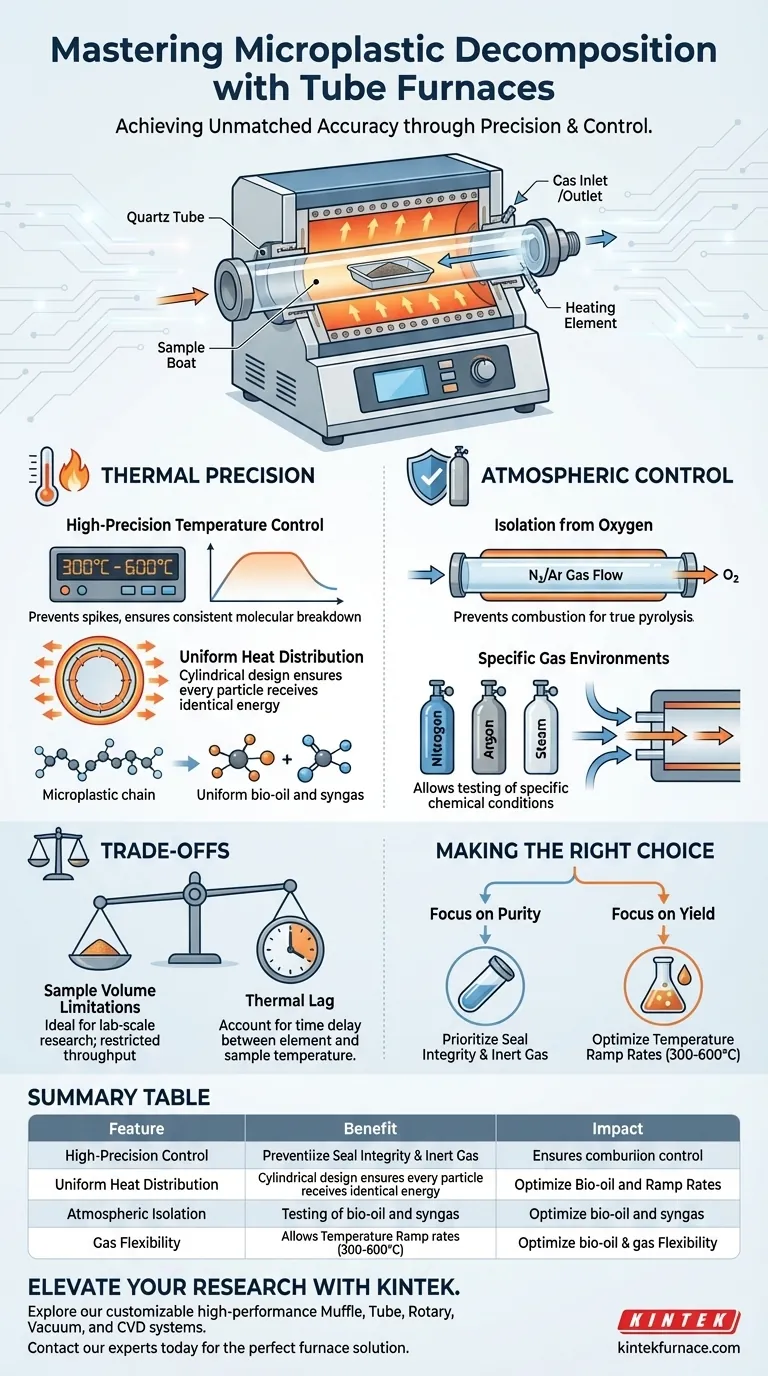

Achieving Thermal Precision

High-Precision Temperature Control

Accuracy in decomposition experiments depends on maintaining exact temperatures, typically between 300°C and 600°C. Tube furnaces utilize digital control systems to monitor and adjust heat output with minimal deviation. This prevents temperature spikes that could alter the chemical composition of the resulting bio-oil or syngas.

Uniform Heat Distribution

Inconsistent heating leads to incomplete decomposition or varied reaction rates within a single sample. Because the heating elements surround the cylindrical work tube, the furnace provides uniform heat along the tube’s entire length. This geometry ensures every particle of the microplastic sample is exposed to the same thermal energy simultaneously.

Predictable Molecular Breakdown

The primary goal of these experiments is to break microplastic molecular chains in a specific way. The stable thermal environment ensures these chains fracture in a predictable pattern. This reproducibility is essential for validating experimental data and comparing results across different studies.

Controlling the Reaction Atmosphere

Isolation from Oxygen

To achieve true pyrolysis (decomposition without combustion), oxygen must be excluded from the reaction. The design of the tube furnace allows for a sealed environment using stable quartz or ceramic tubes. This isolation is critical for preventing the sample from simply burning, which would ruin the experiment.

Specific Gas Environments

Beyond simple isolation, the furnace allows researchers to introduce specific gases to influence the reaction. Systems can flow Nitrogen (N2) or Argon (Ar) to create an inert atmosphere, or steam for specific gasification processes. This capability allows researchers to test how different environments affect the decomposition process without changing other variables.

Understanding the Trade-offs

Sample Volume Limitations

While tube furnaces offer exceptional control, they are generally limited by the diameter of the work tube. This restricts the sample size you can process in a single run, making them ideal for laboratory-scale research but less suited for high-volume throughput without scaling up significantly.

Thermal Lag

There is a physical barrier between the heating elements (outside the tube) and the sample (inside the tube). Users must account for a slight thermal lag, ensuring the internal sample temperature has actually reached the setpoint displayed on the controller before assuming the reaction has started.

Making the Right Choice for Your Goal

- If your primary focus is Chemical Purity: Prioritize the seal integrity of the quartz or ceramic tube to ensure a strictly oxygen-free environment using Nitrogen or Argon.

- If your primary focus is Product Yield (Bio-oil/Syngas): Focus on the precision of the temperature ramp rate within the 300°C to 600°C range to optimize the molecular breakdown.

Control the environment, and you control the chemistry.

Summary Table:

| Feature | Benefit for Microplastic Research | Experimental Impact |

|---|---|---|

| High-Precision Control | Maintains exact 300°C - 600°C range | Prevents chemical spikes; ensures data reproducibility |

| Uniform Heat Distribution | Cylindrical heating around the work tube | Ensures consistent reaction rates across all particles |

| Atmospheric Isolation | Sealed quartz/ceramic tube environment | Eliminates oxygen to prevent combustion (true pyrolysis) |

| Gas Flexibility | Supports Nitrogen, Argon, or Steam flow | Allows testing of specific chemical environments |

Elevate Your Research with Precision Thermal Solutions

Ready to achieve unmatched accuracy in your microplastic decomposition experiments? Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temp furnaces are fully customizable to meet your unique research parameters, ensuring you get the exact thermal environment required for high-quality bio-oil and syngas production.

Don't settle for inconsistent results. Contact KINTEK today to discuss your project requirements with our technical experts and find the perfect furnace solution for your laboratory.

Visual Guide

References

- Dorota Wieczorek, Katarzyna Ławińska. Microplastic Recovery and Conversion Pathways: The Most Recent Advancements in Technologies for the Generation of Renewable Energy. DOI: 10.3390/en18184949

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a quartz tube furnace facilitate diamond water vapor annealing? Enhance Interface Stability at 500 °C

- What core functions does a high-temperature tube furnace provide? Master TiN-Carbon Composite Pyrolysis

- What is the function of a high-temperature tube furnace in the annealing treatment of ZnIn electrodes?

- What are some examples of tube furnace models and their ideal applications? Find Your Perfect Match for Precise Thermal Processing

- Why Use Nitrogen in Lab Tube Furnaces for LFP Relithiation? Ensure Superior Battery Material Restoration

- What are the main features and functions of a laboratory tube furnace? Unlock Precise High-Temp Control for Your Lab

- Why is a tube furnace equipped with a nitrogen environment necessary for biochar? Achieve Precise Pyrolysis Control

- What technological requirements affect tube furnace design? Key Factors for Optimal Performance