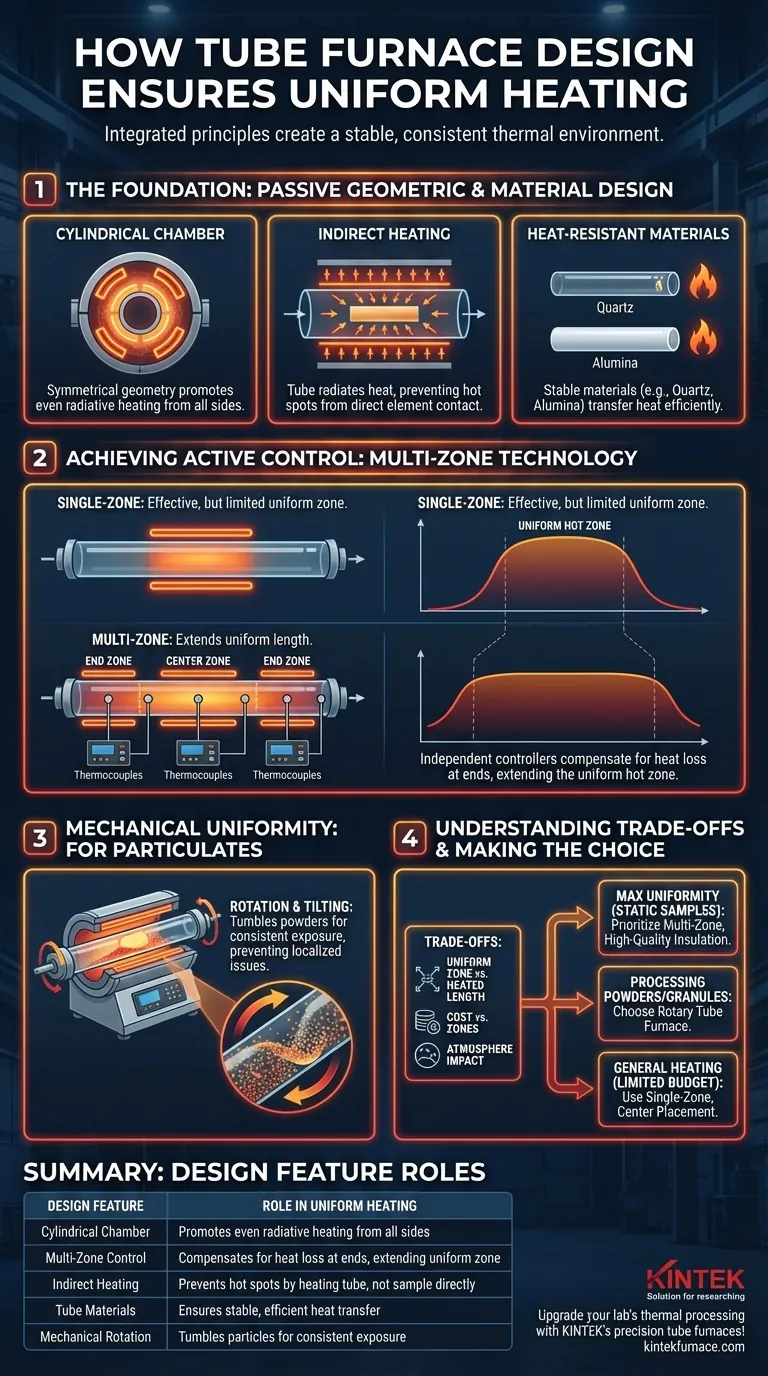

Uniform heating in a tube furnace is not an accident; it is the direct result of several integrated design principles. This precision is achieved through a combination of the furnace's cylindrical geometry, the use of multiple, independently controlled heating zones, and effective insulation that prevents heat from escaping at the ends of the tube. Together, these features create a stable and consistent thermal environment critical for high-precision work.

The core challenge of thermal uniformity is managing heat loss. A well-designed tube furnace doesn't just generate heat; it actively controls its distribution along the entire length of the tube to create a predictable and stable processing environment.

The Foundation: Core Geometric and Material Design

The physical construction of a tube furnace lays the groundwork for thermal uniformity. The shape, materials, and method of heating are all deliberate choices aimed at even heat distribution.

The Cylindrical Chamber

A tube furnace's core is its cylindrical chamber. This geometry ensures that the heating elements, which encircle the tube, are an equal distance from the center at all points around the circumference. This naturally promotes even radiative heating from the outside in.

The Indirect Heating Principle

Tube furnaces operate as "muffle" furnaces. The heating elements do not directly touch the sample; instead, they heat the furnace tube. The tube itself then radiates heat uniformly inward toward the material being processed, preventing hot spots that could occur from direct exposure to the elements.

Heat-Resistant Tube Materials

The material of the process tube, often quartz, alumina, or mullite, is chosen for its thermal stability and conductivity. These materials can withstand high temperatures and transfer heat efficiently and evenly, contributing to a consistent temperature profile inside the tube.

Achieving Active Control: Multi-Zone Technology

While the physical design creates a baseline for uniformity, active temperature management is what allows for true precision. This is where multi-zone control becomes essential.

How Single-Zone Furnaces Work

A single-zone furnace has one set of heating elements and one controller. While effective for many tasks, temperature naturally drops off near the ends of the tube where heat escapes. This results in a shorter, truly uniform hot zone in the center.

The Power of Multi-Zone Control

A multi-zone furnace divides the heated length into three or more sections, each with its own thermocouple and independent controller. The end zones can be programmed to run at a higher temperature than the center zone. This extra heat actively compensates for the energy that is naturally lost at the openings, significantly extending the length of the uniform temperature zone.

Mechanical Uniformity for Particulates

For processing powders or granules, some specialized furnaces feature tube rotation and body tilting. This mechanical movement ensures the material inside is constantly tumbling, exposing all particles to the same thermal conditions and preventing localized overheating or under-heating.

Understanding the Trade-offs

Achieving perfect uniformity involves balancing design complexity, cost, and the physical realities of heat transfer.

Uniform Zone vs. Heated Length

A critical concept is that the uniform hot zone is always shorter than the furnace's total heated length. Heat loss at the ends is unavoidable. A three-zone furnace dramatically improves this ratio but does not eliminate the effect entirely.

Cost vs. Number of Zones

Greater uniformity requires greater complexity. A three-zone furnace provides significantly better uniformity than a single-zone model but at a higher cost due to the additional controllers, thermocouples, and more complex wiring.

Atmosphere and Pressure Impact

Running a process under a vacuum or a flowing gas can also affect temperature uniformity. The movement of gas or the lack of it (in a vacuum) changes the heat transfer dynamics within the tube, which may require adjustments to the temperature settings to maintain uniformity.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the precision your process requires.

- If your primary focus is maximum uniformity for static samples: Prioritize a multi-zone (typically three-zone) furnace and use high-quality insulation plugs to minimize end losses.

- If your primary focus is processing powders or granules: A rotary tube furnace is the superior choice for ensuring all particles receive uniform heat exposure.

- If your primary focus is general heating on a limited budget: A single-zone furnace is effective, provided you place your sample directly in the center of the tube where the temperature is most stable.

By understanding these design principles, you can confidently select and operate a tube furnace to achieve the precise, repeatable thermal processing your work demands.

Summary Table:

| Design Feature | Role in Uniform Heating |

|---|---|

| Cylindrical Chamber | Promotes even radiative heating from all sides |

| Multi-Zone Control | Compensates for heat loss at ends, extending uniform zone |

| Indirect Heating | Prevents hot spots by heating tube, not sample directly |

| Tube Materials (e.g., Quartz) | Ensures stable, efficient heat transfer |

| Mechanical Rotation (for powders) | Tumbles particles for consistent exposure |

Upgrade your lab's thermal processing with KINTEK's precision tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we offer advanced solutions like Tube Furnaces, Muffle Furnaces, and CVD/PECVD Systems, with deep customization to meet your unique experimental needs. Ensure uniform heating and reliable results—contact us today to discuss how we can enhance your workflow!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents