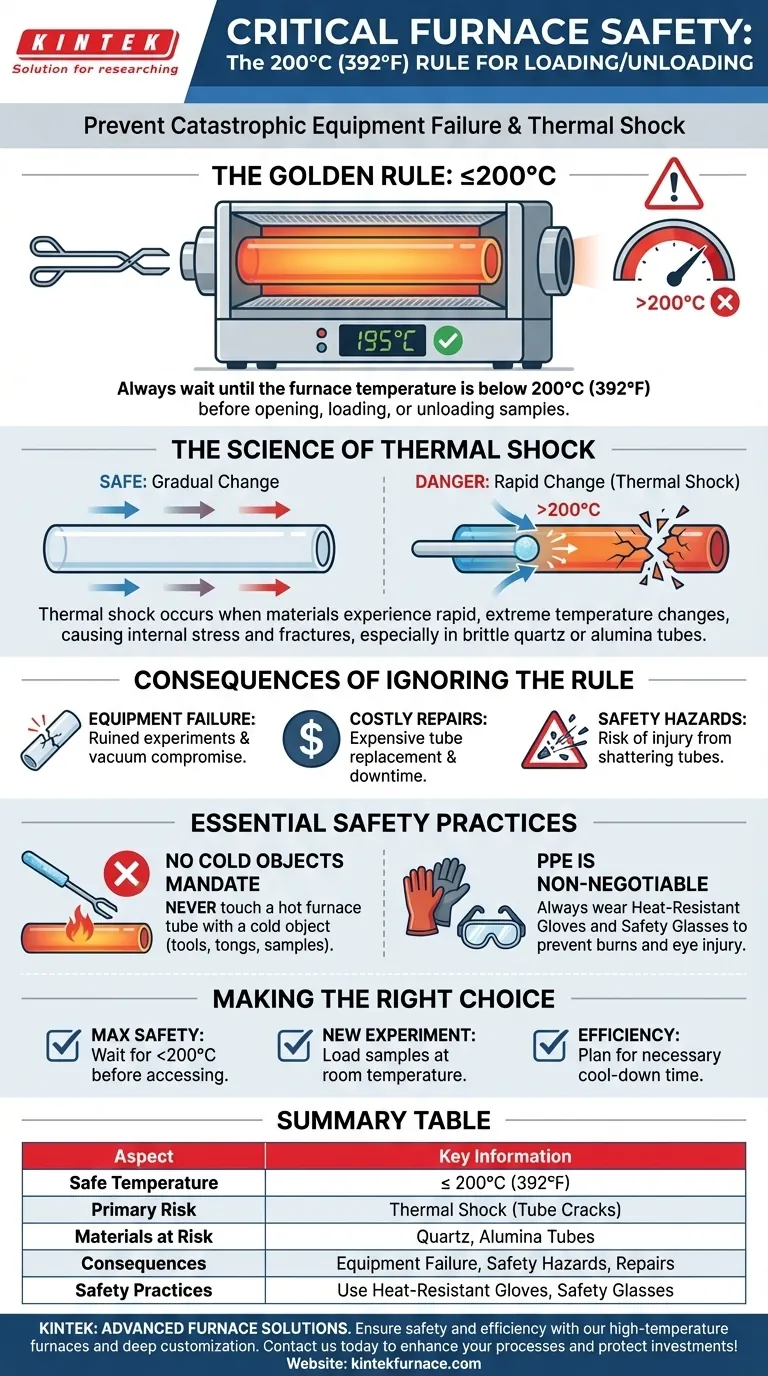

To prevent catastrophic equipment failure, your furnace temperature must be at or below 200°C (392°F) before loading or unloading any samples. This critical temperature threshold is designed to protect the furnace's internal components, most notably the processing tube, from the damaging effects of rapid temperature change.

The 200°C rule is not about convenience; it is the primary defense against thermal shock, a phenomenon that can cause brittle furnace tubes to crack or even shatter, leading to costly repairs and significant safety risks.

The Science Behind the 200°C Rule

To operate a furnace safely and effectively, it's essential to understand the physical principle that dictates this rule. The entire procedure is built around mitigating thermal shock.

What is Thermal Shock?

Thermal shock occurs when a material experiences a rapid and extreme change in temperature. This causes different parts of the material to expand or contract at different rates, creating immense internal stress.

Think of pouring cold water into a hot glass baking dish. The sudden temperature difference can cause the glass to crack instantly. The same principle applies to the sensitive components inside a furnace.

Why Furnace Tubes are So Vulnerable

Many high-temperature furnace tubes are made from materials like quartz or alumina. While incredibly durable at stable, high temperatures, they are often brittle at lower temperatures.

When you introduce a room-temperature object—like a sample boat or loading rod—into a tube that is significantly hotter than 200°C, the area of contact cools down instantly. This localized, rapid contraction creates stress that the material cannot withstand, leading to fractures.

The Consequences of Tube Failure

Ignoring the 200°C guideline can have severe consequences beyond a simple broken part.

A cracked tube can ruin a sensitive experiment, compromise the vacuum or controlled atmosphere within the furnace, and lead to expensive and time-consuming repairs. In a worst-case scenario, a shattering tube can create a serious safety hazard from flying debris.

Essential Safety and Operating Practices

Adhering to the temperature limit is the first step. It must be paired with consistent safety protocols to protect both the operator and the equipment.

The "No Cold Objects" Mandate

The rule to keep the furnace below 200°C is part of a broader principle: never touch a hot furnace tube with a cold object. This applies to loading, unloading, or any adjustment.

Even if the furnace is slightly above 200°C, resist the temptation to insert tongs or sample holders. The risk of inducing thermal shock remains unacceptably high.

Personal Protective Equipment (PPE) is Non-Negotiable

Even at 200°C, surfaces are hot enough to cause severe burns. Always wear the proper personal protective equipment.

Heat-resistant gloves are mandatory to protect your hands from burns when handling tools or parts near the furnace opening.

Safety glasses or goggles are equally critical. They protect your eyes from ambient heat, stray sparks, or potential debris in the unlikely event of a component failure.

Making the Right Choice for Your Process

Following these guidelines is straightforward. Use this checklist to ensure you are operating safely and preserving the integrity of your equipment.

- If your primary focus is maximum safety and equipment life: Always wait for the furnace display to read below 200°C before opening the chamber or inserting any tools.

- If you are beginning an experiment: Load your sample into the furnace tube while the entire system is at room temperature, before you begin the heating cycle.

- If you are concerned about workflow efficiency: Factor the necessary cool-down time into your experimental planning to avoid pressure to unload the furnace while it is still too hot.

Ultimately, treating the 200°C limit as an unbreakable rule protects your investment, your experiment, and your personal safety.

Summary Table:

| Aspect | Key Information |

|---|---|

| Safe Temperature | ≤ 200°C (392°F) |

| Primary Risk | Thermal shock causing tube cracks |

| Materials at Risk | Quartz, alumina furnace tubes |

| Consequences | Equipment failure, safety hazards, costly repairs |

| Safety Practices | Use heat-resistant gloves and safety glasses |

Ensure your lab operates safely and efficiently with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, preventing issues like thermal shock. Contact us today to discuss how our products can enhance your processes and protect your investments!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety