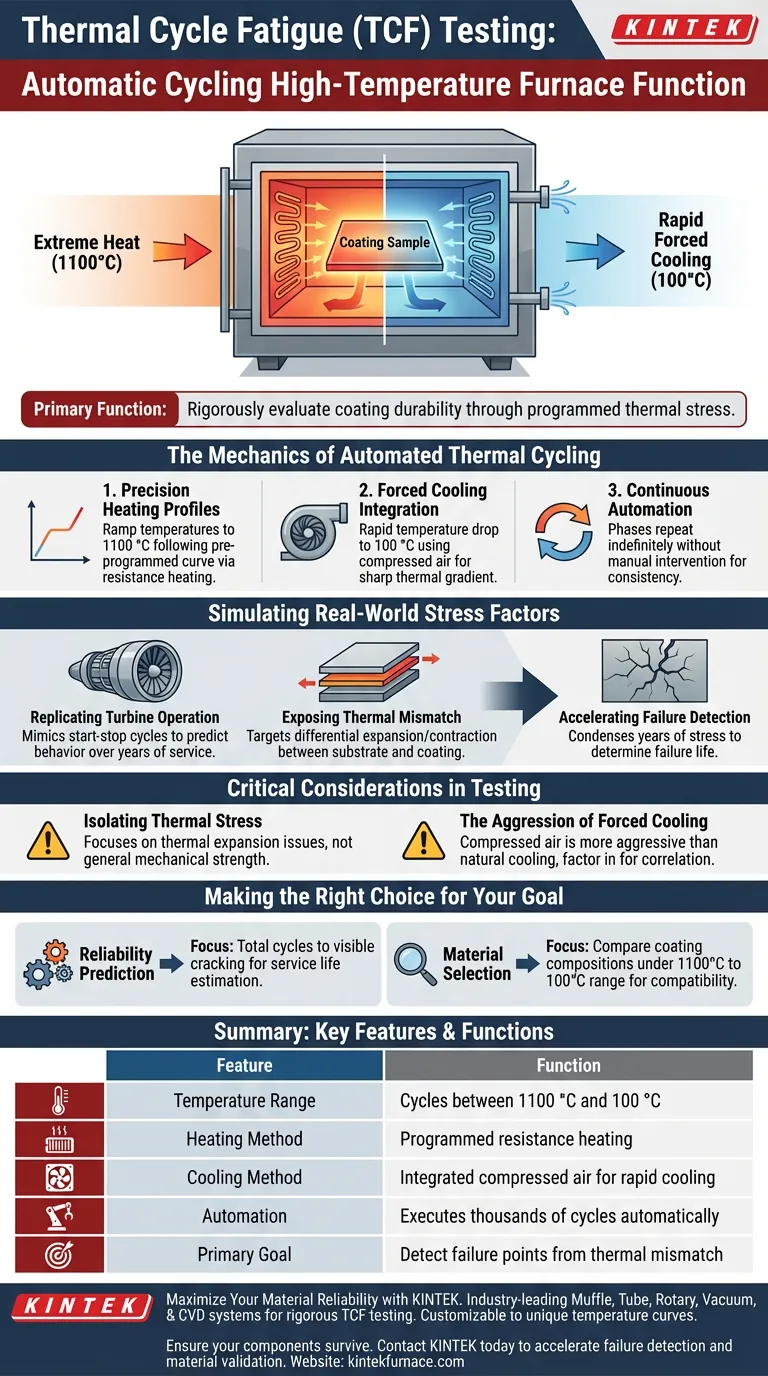

The primary function of an automatic cycling high-temperature box-type resistance furnace is to rigorously evaluate the durability of coating samples through programmed thermal stress. It operates by executing preset temperature control curves that alternate the sample between extreme heat (typically reaching 1100 °C) and rapid forced cooling (dropping to roughly 100 °C).

The core value of this equipment lies in its ability to replicate the harsh "start-stop" operational cycles of turbine engines. By accelerating these thermal shifts in a controlled environment, it exposes the failure points caused by thermal mismatch, providing a quantifiable metric for the coating's expected lifespan and reliability.

The Mechanics of Automated Thermal Cycling

Precision Heating Profiles

The furnace does not simply maintain a static temperature. It utilizes resistance heating to ramp temperatures up to 1100 °C following a specific, pre-programmed curve.

Forced Cooling Integration

To simulate the rapid temperature drops found in real-world operations, the system employs compressed air. This forces the temperature down to 100 °C quickly, creating a sharp thermal gradient.

Continuous Automation

The "automatic" nature of the device allows these heating and cooling phases to repeat indefinitely without manual intervention. This ensures consistency across hundreds or thousands of cycles, which is required for statistical validity.

Simulating Real-World Stress Factors

Replicating Turbine Operation

Turbine blades endure extreme stress every time an engine is turned on (heated) and turned off (cooled). This furnace mimics these specific start-stop cycles to predict how a part will behave over years of service.

Exposing Thermal Mismatch

Materials expand and contract at different rates when heated. This device specifically targets the "thermal mismatch" between a substrate and its coating.

Accelerating Failure Detection

By condensing years of thermal stress into a shorter testing period, engineers can determine the "failure life" of a coating. This prevents unreliable materials from moving to the manufacturing stage.

Critical Considerations in Testing

Isolating Thermal Stress

It is important to recognize that this test isolates thermal expansion and contraction issues. It specifically targets the integrity of the bond between layers rather than general mechanical strength.

The Aggression of Forced Cooling

The use of compressed air creates a more aggressive shock than natural cooling. While efficient for testing, this intensity must be factored in when correlating lab results with field data.

Making the Right Choice for Your Goal

To get the most out of Thermal Cycle Fatigue testing, align your approach with your specific engineering objectives:

- If your primary focus is Reliability Prediction: Focus on the total number of cycles the sample survives before visible cracking occurs to estimate service life.

- If your primary focus is Material Selection: Compare how different coating compositions handle the specific 1100 °C to 100 °C range to identify the most compatible thermal match.

Validating thermal compatibility through rigorous cycling is the only way to ensure coating integrity under the extreme demands of turbine operation.

Summary Table:

| Feature | Function in TCF Testing |

|---|---|

| Temperature Range | Cycles between 1100 °C (heating) and 100 °C (cooling) |

| Heating Method | Programmed resistance heating for precise ramp profiles |

| Cooling Method | Integrated compressed air for rapid forced cooling |

| Automation | Executes thousands of cycles without manual intervention |

| Primary Goal | Detect failure points caused by thermal expansion mismatch |

Maximize Your Material Reliability with KINTEK

Don't leave the integrity of your coatings to chance. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically engineered to handle the rigorous demands of thermal cycle fatigue testing. Backed by expert R&D and world-class manufacturing, our high-temperature lab furnaces are fully customizable to meet your unique temperature curves and cooling requirements.

Ensure your components survive the harshest environments. Contact KINTEK today to discuss your testing needs and discover how our precision thermal solutions can accelerate your failure detection and material validation.

Visual Guide

References

- Madhura Bellippady, Nicolaie Markocsan. Performance of Atmospheric Plasma-Sprayed Thermal Barrier Coatings on Additively Manufactured Super Alloy Substrates. DOI: 10.3390/coatings14050626

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is a box-type atmosphere furnace? Master Controlled Heat for Material Processing

- What is the purpose of using a high-temperature atmosphere furnace for the secondary cleaning of recycled carbon fibers?

- How does a furnace atmosphere protect materials from surface reactions? Master Controlled Heat Treatment

- What is the purpose of annealing prepared thin films in an argon environment? Optimize Structure & Prevent Oxidation

- What are the main components of a box-type atmosphere furnace? Essential Parts for Precise Thermal Processing

- What role does an electric furnace with a precision temperature controller play in biochar prep? Master High Performance

- Which process is a retort furnace useful to carry? Master Heat Treatment with Absolute Atmospheric Control

- What safety features are included in the box type annealing atmosphere furnace? Ensure Operator and Equipment Protection