To ensure operational safety, a box-type annealing atmosphere furnace integrates several critical safety systems. These primarily include electrical protections like overcurrent and overvoltage safeguards, thermal protection against overheating, and physical containment features such as a reliably sealed furnace door to prevent atmosphere leakage. In the event of a fault, these systems are designed to automatically cut power and trigger an audible or visual alarm.

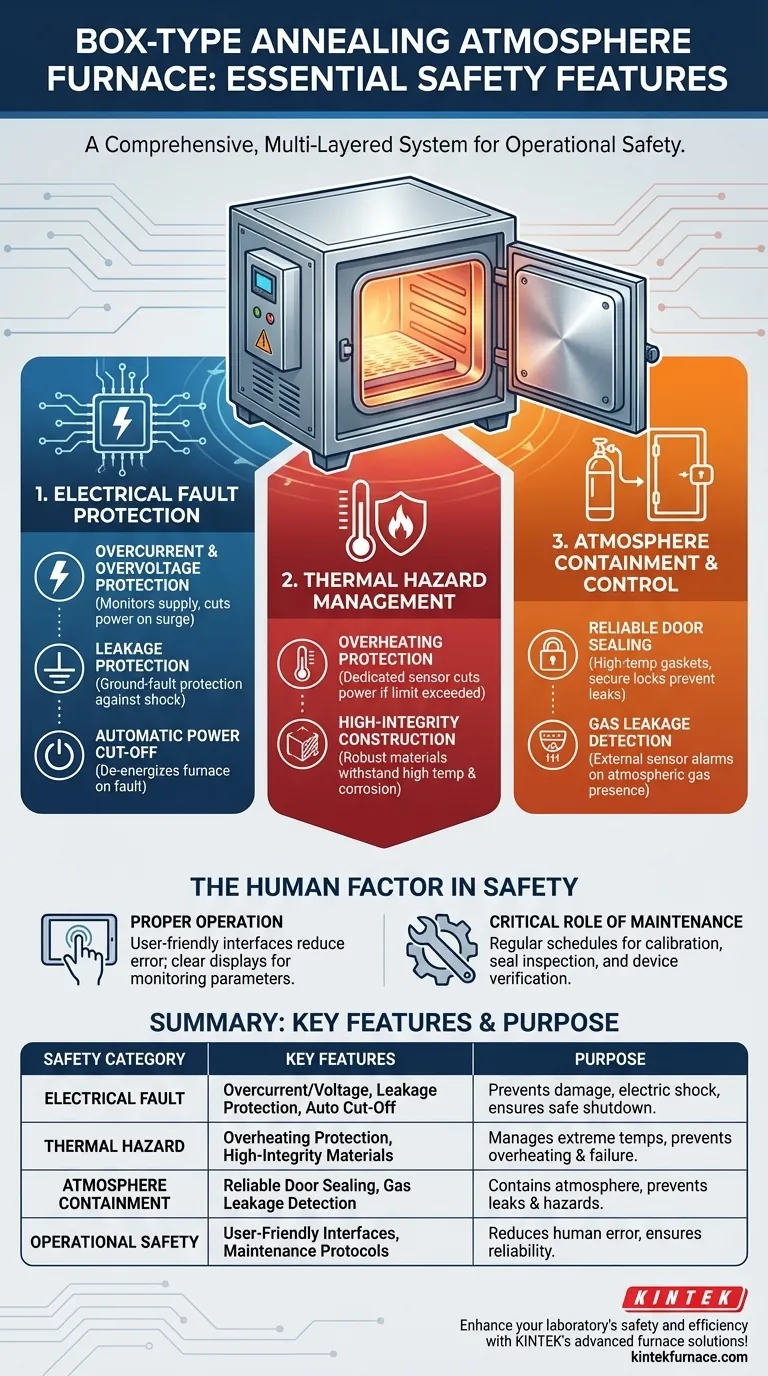

The safety of a box-type annealing furnace is not based on a single feature, but on a comprehensive, multi-layered system. This system works to prevent electrical faults, manage extreme temperatures, and contain the controlled atmosphere, ensuring protection for both the operator and the equipment.

A Multi-Layered Approach to Furnace Safety

A modern atmosphere furnace must manage three distinct categories of risk: electrical hazards, thermal hazards, and atmospheric hazards. The safety features are designed to address each of these areas independently and collectively.

Electrical Fault Protection

The electrical system is the furnace's nerve center, and its protection is paramount for preventing equipment damage and ensuring operator safety.

Overcurrent and Overvoltage Protection This is a fundamental safeguard for the furnace's internal components. It monitors the electrical supply and immediately cuts power if it detects a surge or abnormal current draw, preventing damage to the sensitive control systems and heating elements.

Leakage Protection Often called ground-fault protection, this feature is a critical life-safety device. It monitors for any electrical current "leaking" to the furnace chassis, which could happen if a wire becomes frayed. If a leak is detected, it instantly shuts off power to prevent the risk of severe electric shock to an operator.

Automatic Power Cut-Off Nearly all safety systems are tied to an automatic power cut-off mechanism. Whether the fault is electrical or thermal, the system's primary response is to de-energize the furnace, placing it in a safe state until the issue can be diagnosed and resolved.

Thermal Hazard Management

Controlling extreme heat is the furnace's primary function, but it also represents a significant hazard if not properly managed.

Overheating Protection This system uses a dedicated temperature sensor, separate from the primary control thermocouple. If the furnace temperature exceeds a pre-set safety limit due to a control failure, this system overrides all commands and cuts power to the heating elements, preventing catastrophic damage to the workpiece, insulation, and the furnace itself.

High-Integrity Construction Materials Safety is also a function of design and material selection. The furnace chamber and door seals are built from high-quality materials engineered to withstand high temperatures and resist corrosion over long-term operation, ensuring structural integrity under constant thermal stress.

Atmosphere Containment and Control

The controlled atmosphere is essential for the annealing process but can pose a risk if it leaks into the surrounding environment.

Reliable Door Sealing The furnace door is a critical boundary. It is engineered with a robust sealing structure, often using high-temperature gaskets and secure locking mechanisms, to maintain a positive internal pressure and prevent any leakage of the process atmosphere.

Gas Leakage Detection While not always standard on every model, many atmosphere furnace systems incorporate an external gas leakage detector. This sensor monitors the air around the furnace for the specific gases being used (e.g., hydrogen, argon). If a leak is detected from a failed seal or connection, it will trigger an alarm, providing a crucial early warning.

Understanding the Human Factor in Safety

Engineered safety features are only part of the equation. Operational and maintenance practices are just as critical to ensuring a safe environment.

The Importance of Proper Operation

Modern furnaces often feature user-friendly digital interfaces. These systems contribute to safety by reducing the likelihood of user error. Clear displays for setting parameters and monitoring the furnace's status help ensure the equipment is operated within its designed limits.

The Critical Role of Maintenance

Safety systems are only reliable if they are properly maintained. Regular maintenance schedules are a vital safety protocol. This includes calibrating the temperature control and overheating systems, inspecting door seals for wear, and verifying the function of all electrical protection devices. A neglected safety feature is an unreliable one.

Making the Right Choice for Your Goal

When evaluating a furnace, consider how its safety features align with your primary operational priorities.

- If your primary focus is operator safety: Prioritize furnaces with comprehensive electrical leakage protection, external gas leakage detectors, and well-designed door interlocks.

- If your primary focus is equipment longevity: Look for precise overheating protection, high-quality heating elements, and robust chamber and seal construction.

- If your primary focus is process reliability and uptime: A modular design and a clear diagnostic interface are key, as they simplify the maintenance and troubleshooting of all systems, including safety features.

Ultimately, a truly safe furnace environment is achieved by combining robust engineering with diligent operational and maintenance protocols.

Summary Table:

| Safety Category | Key Features | Purpose |

|---|---|---|

| Electrical Fault Protection | Overcurrent/Overvoltage Protection, Leakage Protection, Automatic Power Cut-Off | Prevents equipment damage and electric shock, ensures safe shutdown during faults |

| Thermal Hazard Management | Overheating Protection, High-Integrity Construction Materials | Manages extreme temperatures, prevents overheating damage and structural failure |

| Atmosphere Containment | Reliable Door Sealing, Gas Leakage Detection | Contains controlled atmospheres, prevents leaks and environmental hazards |

| Operational Safety | User-Friendly Interfaces, Maintenance Protocols | Reduces human error, ensures system reliability through regular upkeep |

Enhance your laboratory's safety and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature furnaces, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, offering robust safety features for operator protection and equipment longevity. Contact us today to discuss how our tailored solutions can meet your specific requirements and elevate your processes!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality