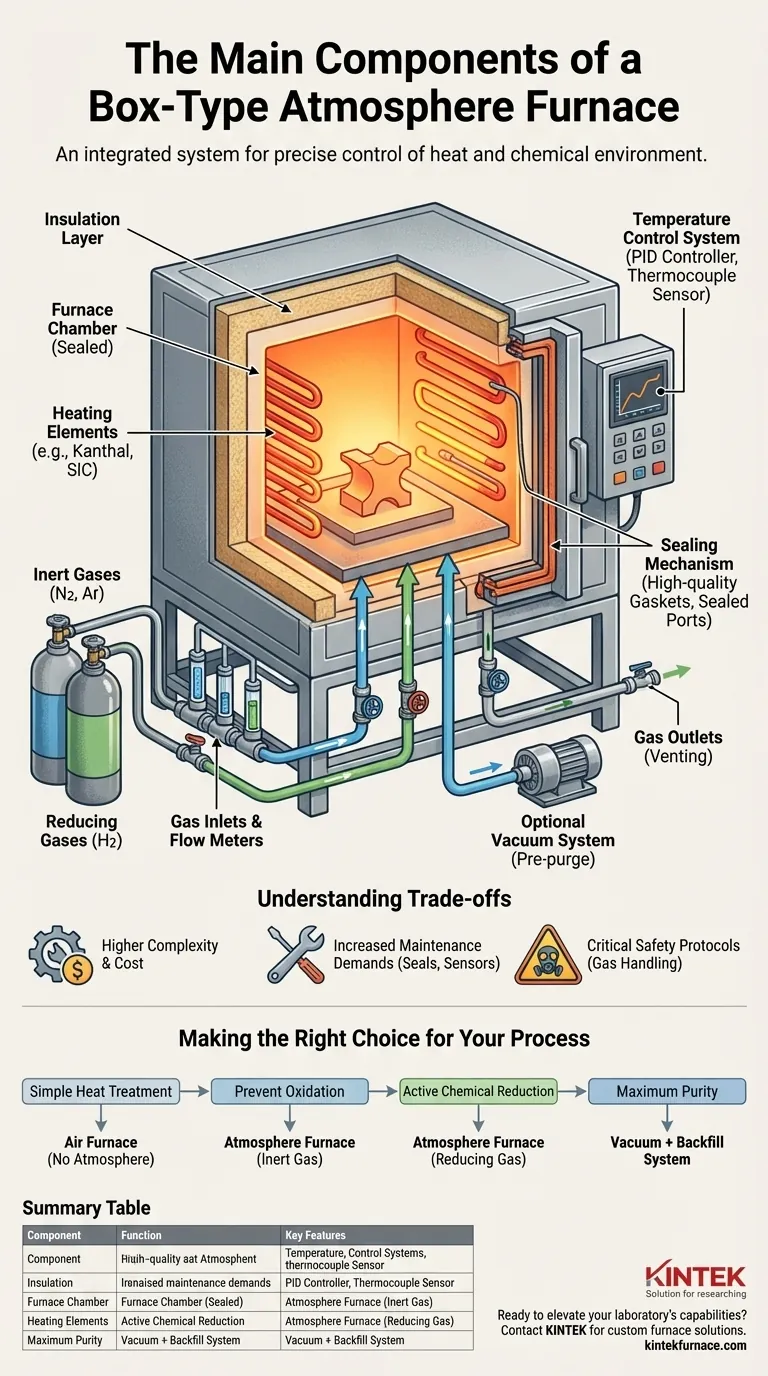

At its core, a box-type atmosphere furnace is an integrated system built around five key components: the furnace chamber, a heating system, an insulation layer, a temperature control system, and a dedicated atmosphere control system. While a standard furnace only manages heat, an atmosphere furnace adds the critical capability of precisely controlling the chemical environment inside the chamber.

A box-type atmosphere furnace should not be viewed as just a hot box. It is a sealed environmental system where the atmosphere control components—the gas inlets, outlets, and seals—are just as critical as the heating elements and temperature controller for achieving the desired material processing results.

The Core Structure: Containing the Environment

The physical body of the furnace serves to contain both the high temperatures and the specialized atmosphere, ensuring safety, efficiency, and process integrity.

The Furnace Chamber

This is the central workspace, a sealed box constructed from high-temperature-resistant materials. Its primary job is to contain the workpiece and the controlled atmosphere, preventing any interaction with the outside air.

The Insulation Layer

Surrounding the chamber is a thick layer of insulation. This component is crucial for minimizing heat loss, which improves energy efficiency and allows the furnace to reach and maintain high temperatures. It also keeps the outer shell of the furnace cool for operator safety.

The Sealing Mechanism

This is what distinguishes an atmosphere furnace from a standard air furnace. High-quality door gaskets and sealed ports are essential to prevent the controlled atmosphere from leaking out and, more importantly, to stop oxygen from leaking in and contaminating the process.

The Heating System: Generating and Managing Temperature

This system is the engine of the furnace, responsible for creating and regulating the thermal energy required for the process.

Heating Elements

These are the components that generate heat when electricity is passed through them. Common materials include high-resistance wire (like Kanthal) or more robust silicon carbide (SiC) or molybdenum disilicide (MoSi2) rods for higher temperatures. They are typically arranged to provide uniform heating throughout the chamber.

The Temperature Control System

This is the brain of the heating operation. It uses a thermocouple (a sensor) to measure the temperature inside the chamber and a PID controller to intelligently turn the heating elements on and off to precisely follow a programmed temperature profile. Modern systems are highly programmable, allowing for complex multi-step heating and cooling cycles.

The Atmosphere System: Controlling the Chemical Environment

This is the most defining feature of an atmosphere furnace. It allows you to replace the air inside the chamber with a specific gas or gas mixture to enable specific chemical reactions or prevent unwanted ones like oxidation.

Gas Inlets and Outlets

The furnace chamber is equipped with ports for introducing process gases and for safely venting them. The inlet system often includes flow meters to precisely regulate the volume of gas entering the furnace.

Atmosphere Control and Mixing

This system manages the flow of various gases, such as inert gases (Nitrogen, Argon) to prevent reactions, or reducing gases (Hydrogen) to actively remove oxygen. The ability to control gas flow rates is critical for maintaining a stable, positive pressure inside the furnace, which helps prevent air from leaking in.

Optional Vacuum System

For applications requiring the highest purity, some atmosphere furnaces include a vacuum pump. This is used to first remove nearly all of the air and moisture from the chamber before backfilling it with the desired high-purity process gas.

Understanding the Trade-offs

Choosing an atmosphere furnace involves accepting a higher level of complexity compared to a simple air furnace. Understanding these trade-offs is crucial.

Higher Complexity and Cost

The addition of gas plumbing, flow controllers, and robust sealing mechanisms makes an atmosphere furnace inherently more complex and expensive to purchase and operate than its standard air-only counterpart.

Increased Maintenance Demands

Door seals and gaskets are wear items that require regular inspection and replacement to ensure a proper seal. Gas lines, valves, and sensors also add to the list of components that need periodic maintenance to ensure reliability.

Critical Safety Protocols

Operating with bottled gases introduces new safety considerations. Inert gases like nitrogen and argon are asphyxiants in high concentrations, while reducing gases like hydrogen can be flammable or explosive. Proper ventilation and strict safety protocols are non-negotiable.

Making the Right Choice for Your Process

Your specific material processing goal determines which components are most critical.

- If your primary focus is simple heat treatment in air: A standard box furnace without atmosphere controls is a simpler, more cost-effective solution.

- If your primary focus is preventing oxidation (e.g., bright annealing, brazing): An atmosphere furnace with a reliable sealing system and inert gas (N2, Ar) capability is essential.

- If your primary focus is active chemical reduction (e.g., decarburization): You need a furnace specifically designed to safely handle reducing gases like hydrogen and provide precise flow control.

- If your primary focus is maximum purity for sensitive materials: A system featuring a vacuum purge cycle before backfilling with high-purity gas is the ideal choice.

Understanding how these components work together empowers you to select and operate the correct tool to achieve precise control over your thermal and chemical processing environment.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Furnace Chamber | Contains workpiece and atmosphere | Sealed, high-temperature resistant materials |

| Heating System | Generates and regulates heat | Heating elements (e.g., Kanthal, SiC), PID controller |

| Insulation Layer | Minimizes heat loss | Improves efficiency and safety |

| Temperature Control System | Manages temperature precisely | Thermocouple sensor, programmable cycles |

| Atmosphere Control System | Controls chemical environment | Gas inlets/outlets, flow meters, optional vacuum |

| Sealing Mechanism | Prevents leaks | High-quality gaskets and sealed ports |

Ready to elevate your laboratory's capabilities with a custom box-type atmosphere furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're focused on preventing oxidation, enabling chemical reduction, or achieving maximum purity, we can design a furnace that precisely meets your experimental requirements. Contact us today to discuss how we can enhance your thermal processing efficiency and results!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance