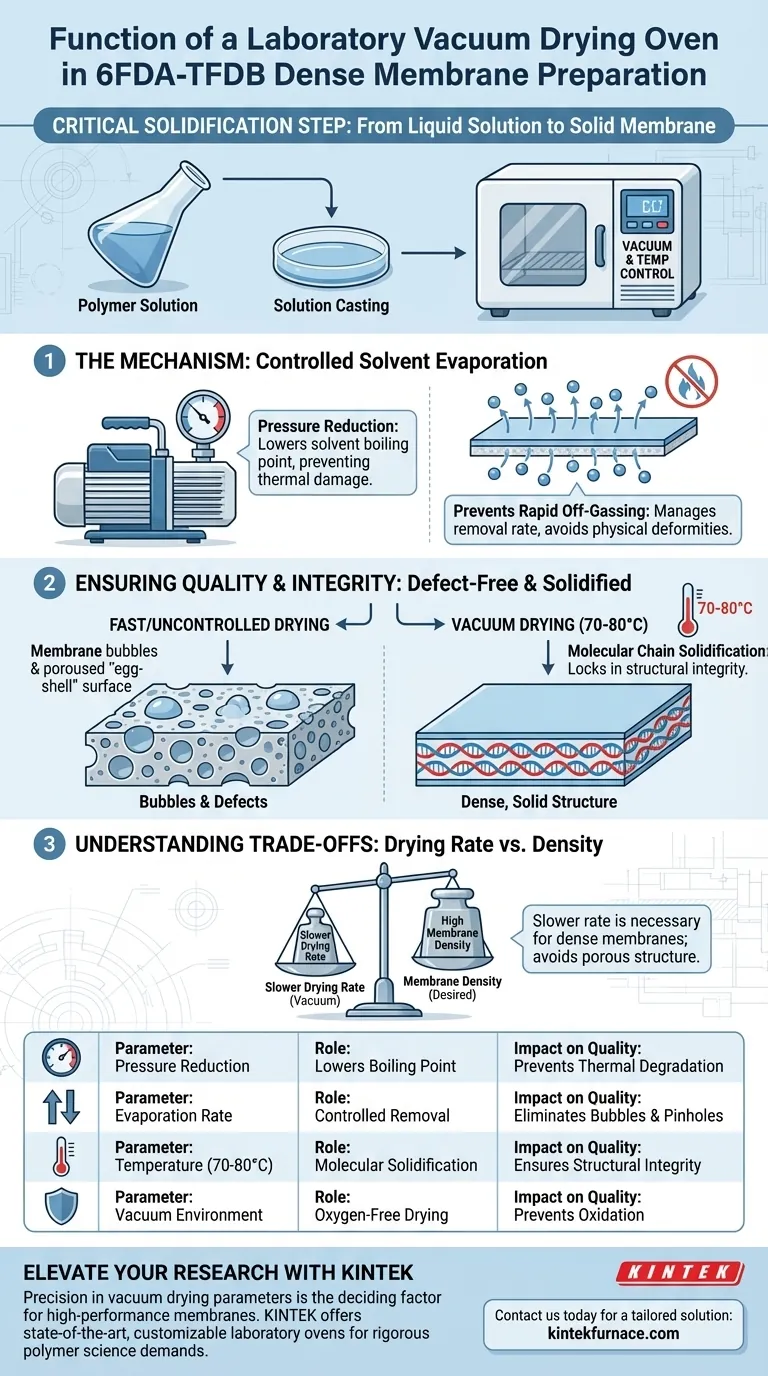

In the preparation of 6FDA-TFDB dense membranes, a laboratory vacuum drying oven acts as the critical solidification instrument following the solution casting process. Its primary function is to facilitate the controlled evaporation of solvents, ensuring the transition from a liquid polymer solution to a solid, structurally sound membrane.

The vacuum oven creates a controlled environment that lowers the solvent boiling point, allowing for thorough removal without the high heat that could damage the polymer. This precise regulation is essential for preventing surface defects, such as bubbles, while ensuring the complete solidification of the molecular chains.

The Mechanism of Solvent Removal

Controlled Evaporation via Pressure Reduction

The central principle of this process is the relationship between pressure and boiling points. By reducing the pressure inside the chamber, the oven allows solvents to evaporate at temperatures significantly lower than their atmospheric boiling points.

Preventing Rapid Off-Gassing

For 6FDA-TFDB membranes, uncontrolled evaporation is detrimental. The vacuum oven manages the rate of solvent removal, preventing the rapid gas expansion that leads to physical deformities in the membrane structure.

Ensuring Membrane Quality and Integrity

Eliminating Surface Defects

One of the most common failure points in membrane fabrication is the formation of residual bubbles. If solvents are removed too quickly or incompletely, gas pockets become trapped within the polymer matrix. The vacuum drying process mitigates this, ensuring a smooth, defect-free surface essential for a "dense" membrane.

Solidification of Molecular Chains

Beyond simple drying, the oven plays a role in the material's final morphology. High-temperature vacuum steps, typically ranging from 70°C to 80°C, drive the complete solidification of the polymer molecular chains. This step locks in the structural integrity required for the membrane to function correctly in separation applications.

Understanding the Trade-offs

Drying Rate vs. Membrane Density

While vacuum drying is effective, it is inherently slower than rapid convective drying methods. However, this slower rate is a necessary trade-off; faster drying methods often result in an "egg-shell" layer or porous structure, which defeats the purpose of creating a dense membrane.

Thermal Balance

There is a delicate balance between temperature and vacuum level. Excessive heat can degrade the polymer or cause rapid skin formation that traps solvent inside (skinning), while insufficient heat under vacuum may leave residual solvent that weakens the mechanical properties of the 6FDA-TFDB.

Making the Right Choice for Your Goal

To maximize the performance of your 6FDA-TFDB membranes, tailor your drying protocol to your specific requirements:

- If your primary focus is defect minimization: Prioritize a gradual ramp in vacuum pressure to prevent the rapid boiling of solvents that causes pinholes and bubbles.

- If your primary focus is structural integrity: Ensure the final drying stage is held at the optimal 70-80°C range long enough to guarantee full solvent extraction and molecular chain solidification.

Precision in your vacuum drying parameters is the deciding factor between a compromised film and a high-performance dense membrane.

Summary Table:

| Parameter | Role in Membrane Preparation | Impact on Quality |

|---|---|---|

| Pressure Reduction | Lowers solvent boiling point | Prevents thermal degradation of polymer |

| Evaporation Rate | Controlled solvent removal | Eliminates bubbles and surface pinholes |

| Temperature (70-80°C) | Molecular chain solidification | Ensures structural integrity and density |

| Vacuum Environment | Oxygen-free drying | Prevents oxidation and contamination |

Elevate Your Membrane Research with KINTEK

Precision is the deciding factor between a compromised film and a high-performance dense membrane. KINTEK provides state-of-the-art laboratory vacuum drying ovens designed to meet the rigorous demands of polymer science.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are working with 6FDA-TFDB or other advanced materials, our lab high-temp furnaces are fully customizable to your unique research needs.

Ready to optimize your solidification process? Contact us today to speak with our technical experts about a tailored solution for your laboratory.

Visual Guide

References

- Xiuling Chen, Nanwen Li. Atomically distributed Al-F3 nanoparticles towards precisely modulating pore size of carbon membranes for gas separation. DOI: 10.1038/s41467-024-54275-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is precise heating rate control necessary? Master Activated Carbon Heat Treatment with KINTEK

- How does calcination temperature affect CuO grain growth? Optimize Nanoporous Film Morphology and Crystallinity

- Why is programmable heating equipment necessary for composite curing? Master Thermal Control for Superior Strength

- What is the primary function of a laboratory electric oven in food waste torrefaction? Ensure Accurate Sample Prep

- What are the advantages of the Laser Hearth Method for Zirconia? Achieve High Purity & Density for Advanced Research

- What is the primary purpose of 24-hour wet milling for SSBSN ceramics? Achieve Atomic-Scale Homogeneity

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- Why is temperature control precision critical for gas diffusion electrodes? Achieve Perfect PTFE Redistribution